HJ Lubtronic SIP

Please select a hotspot to learn more.

HJL360 » HJ Lubtronic SIP overview » HJ Lubtronic SIP

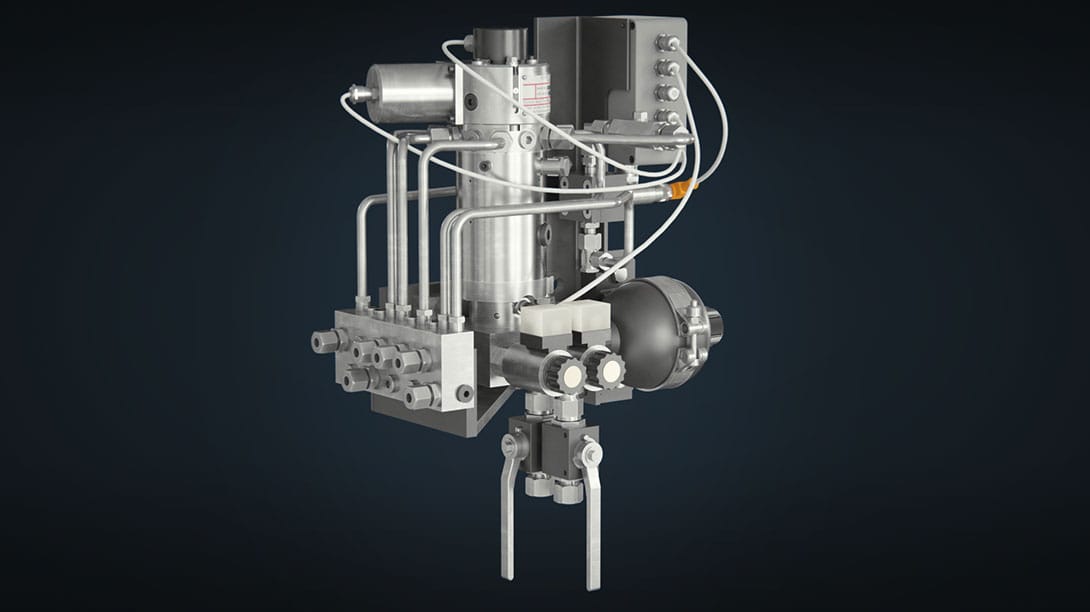

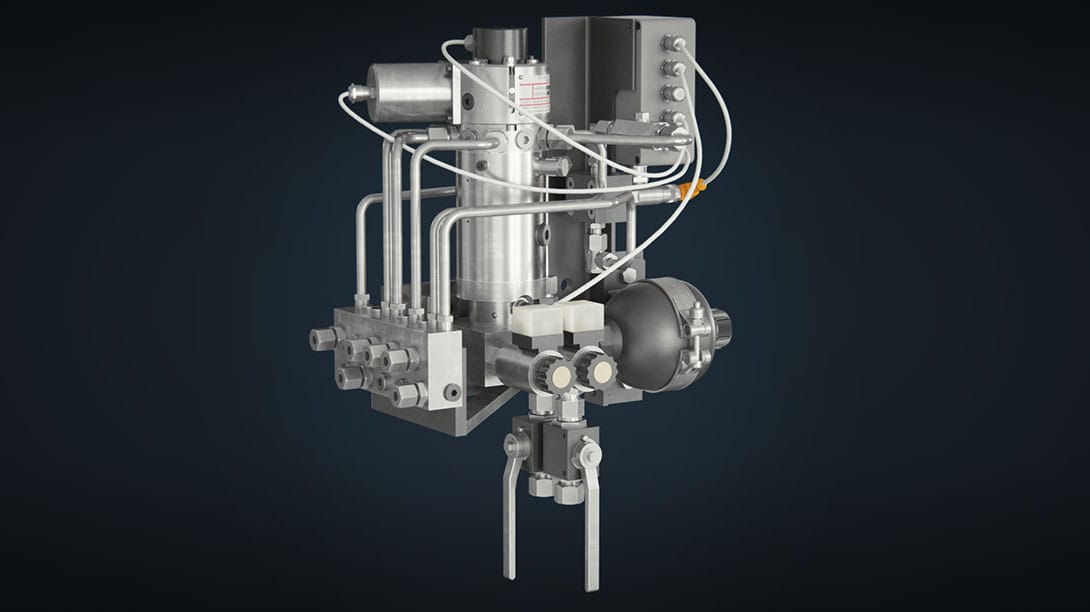

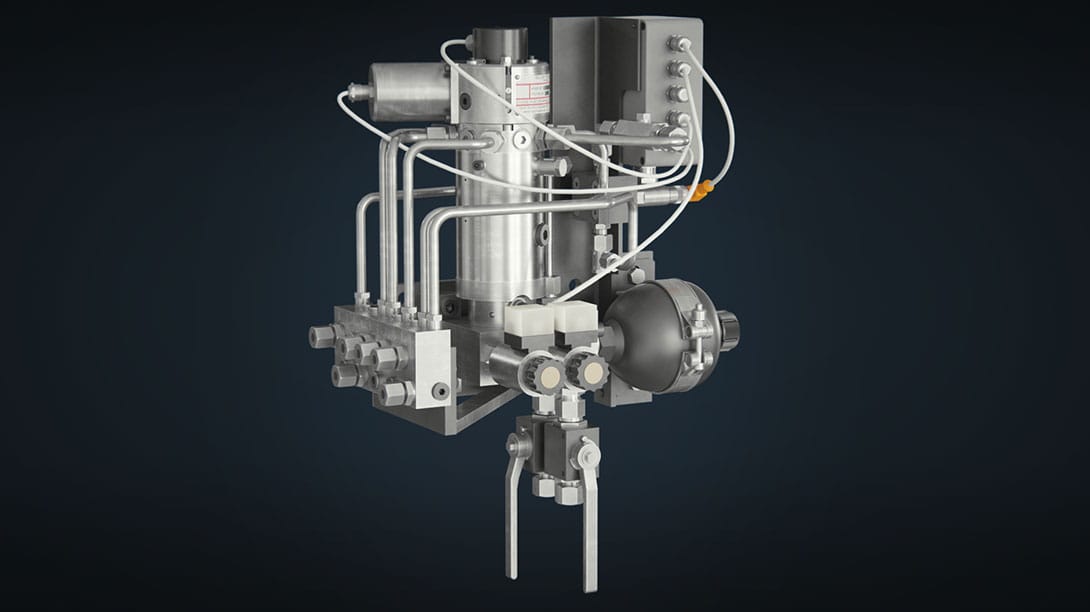

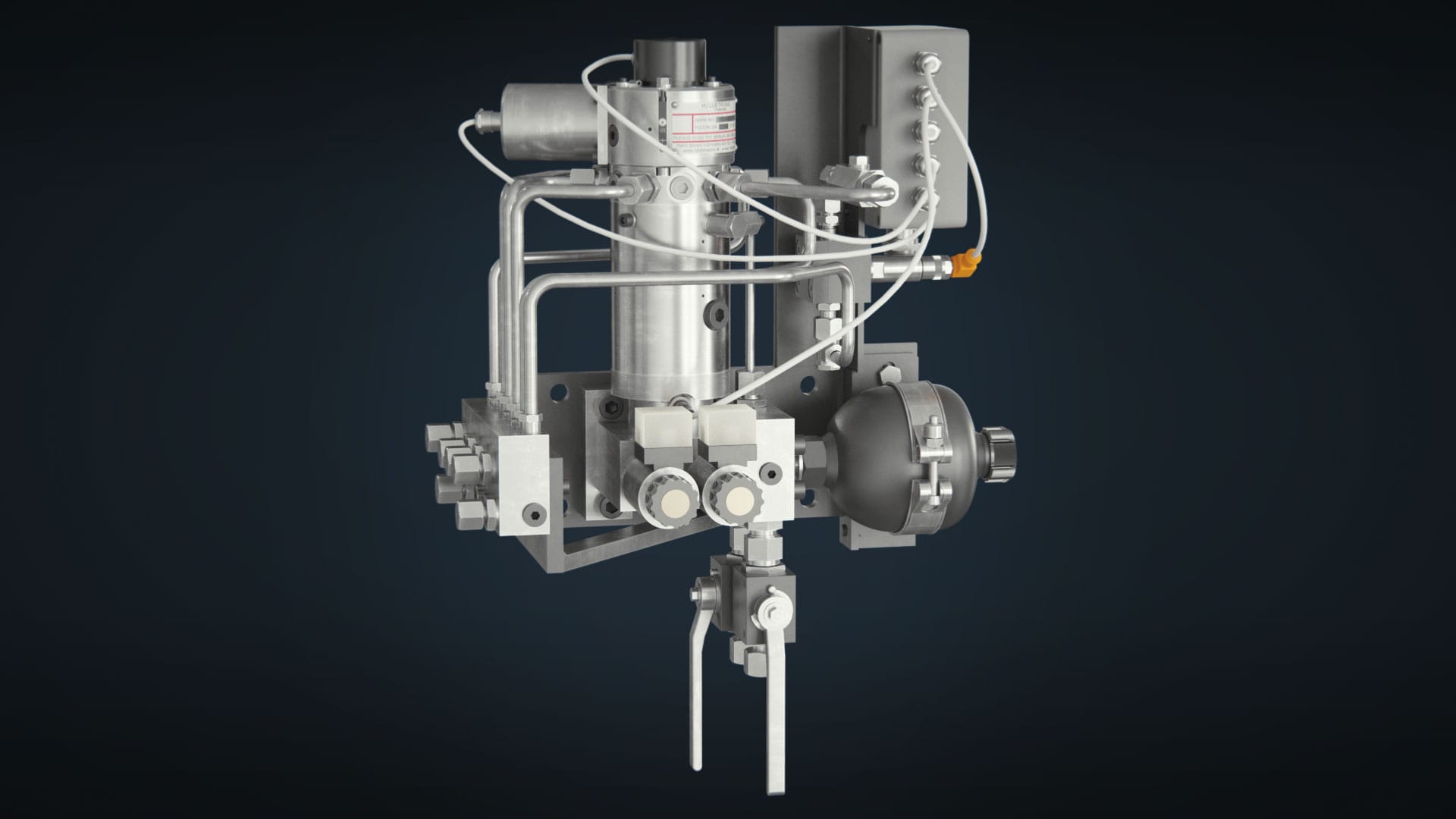

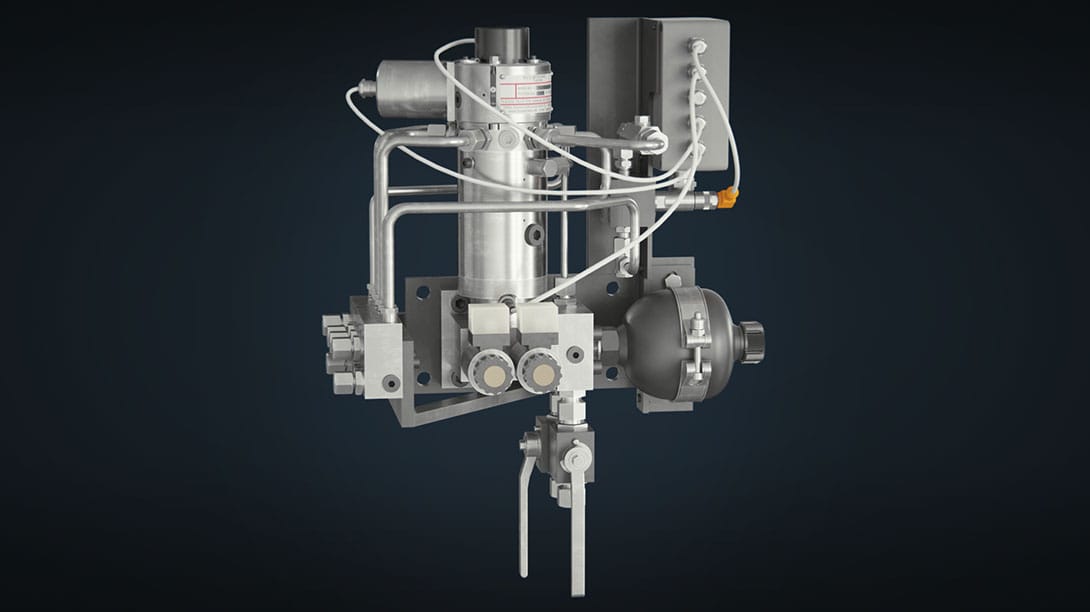

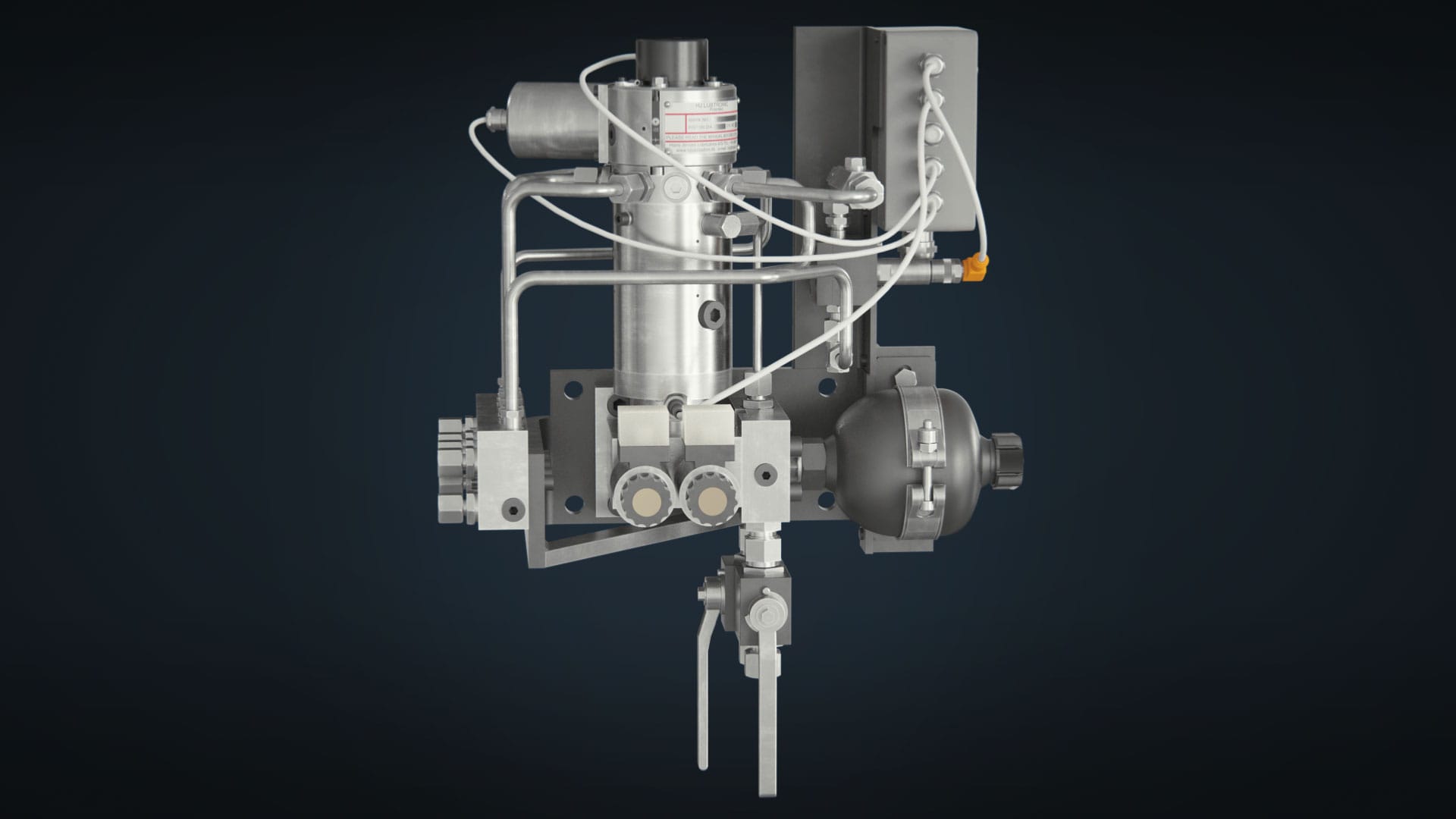

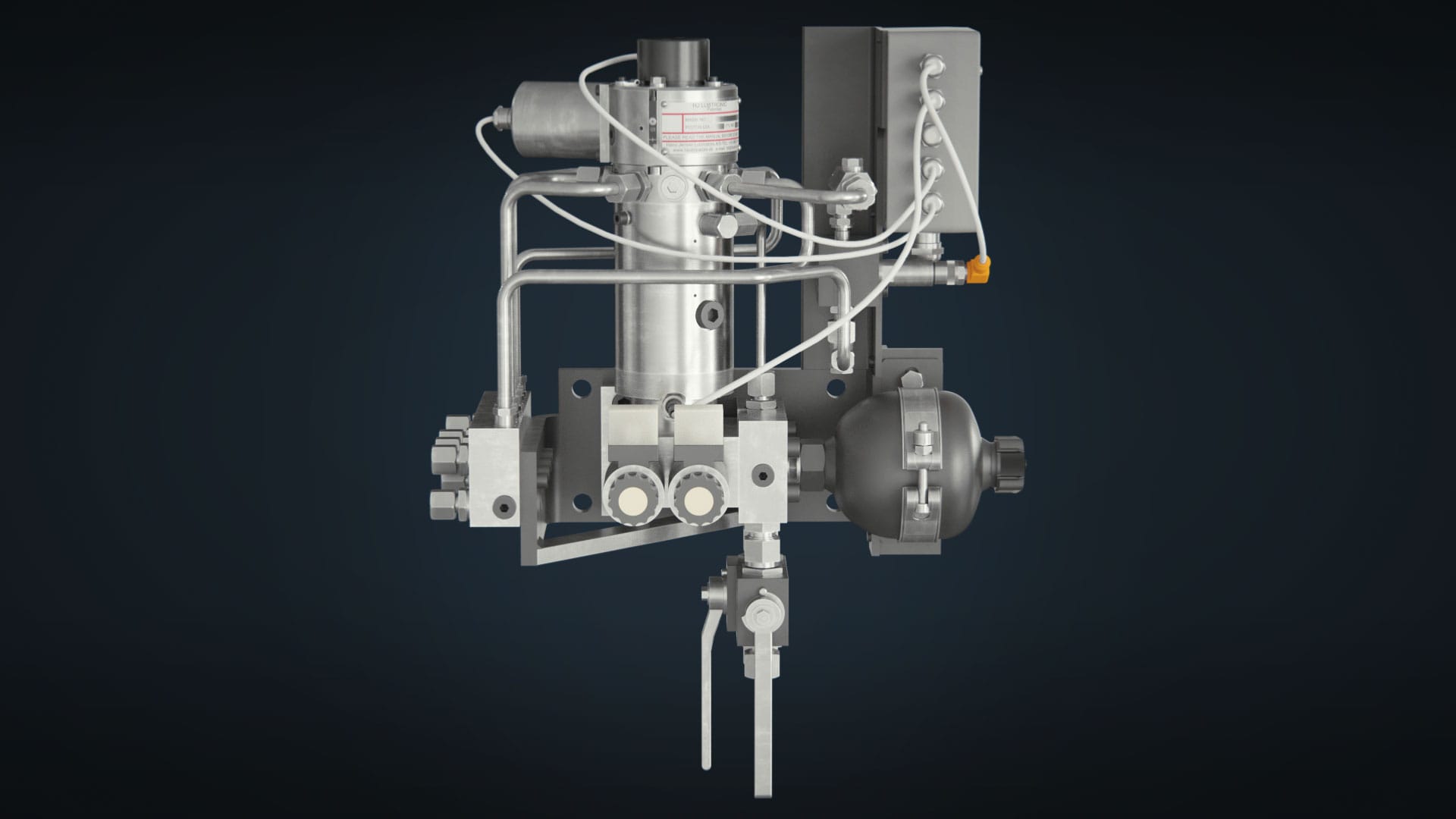

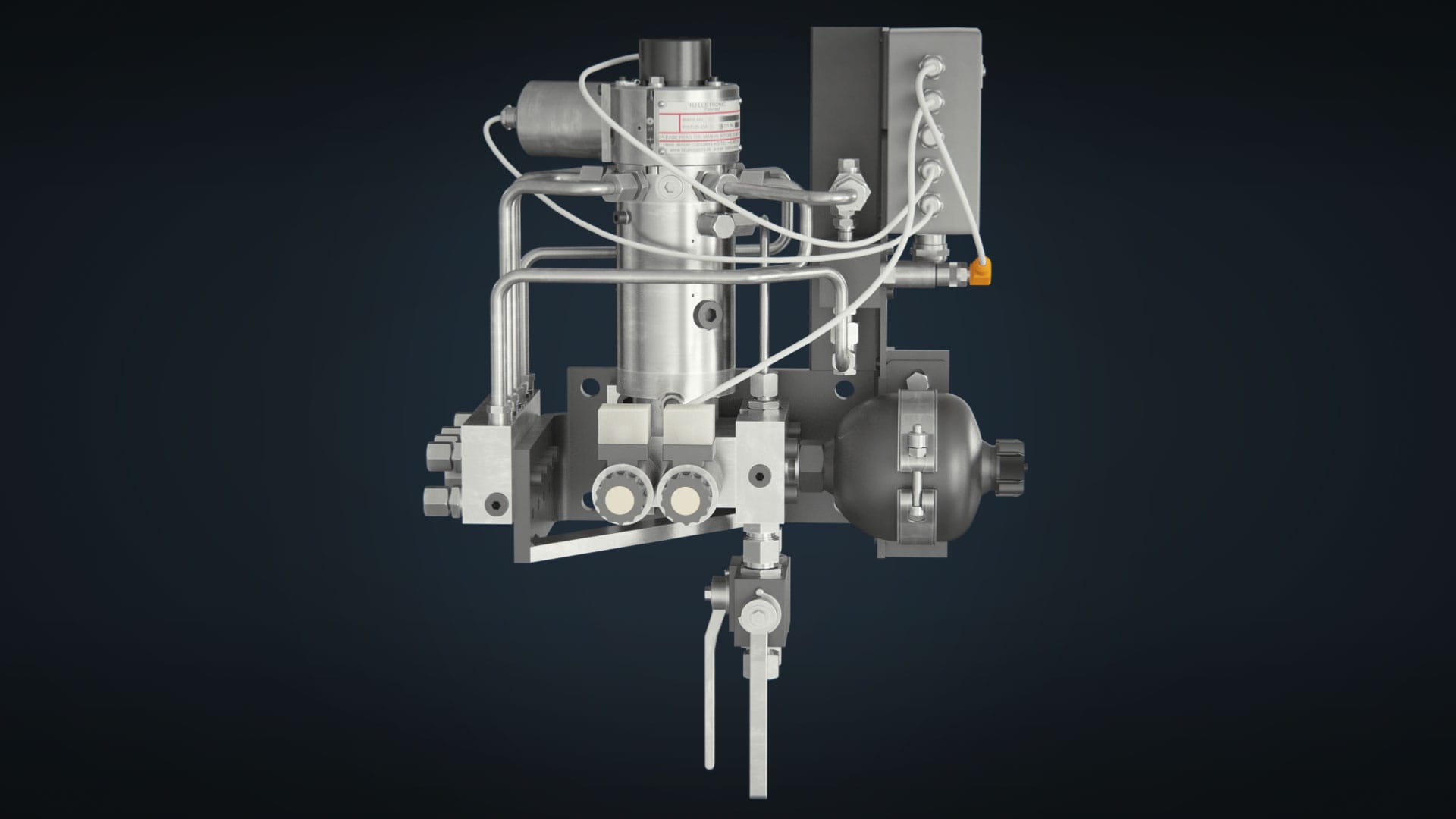

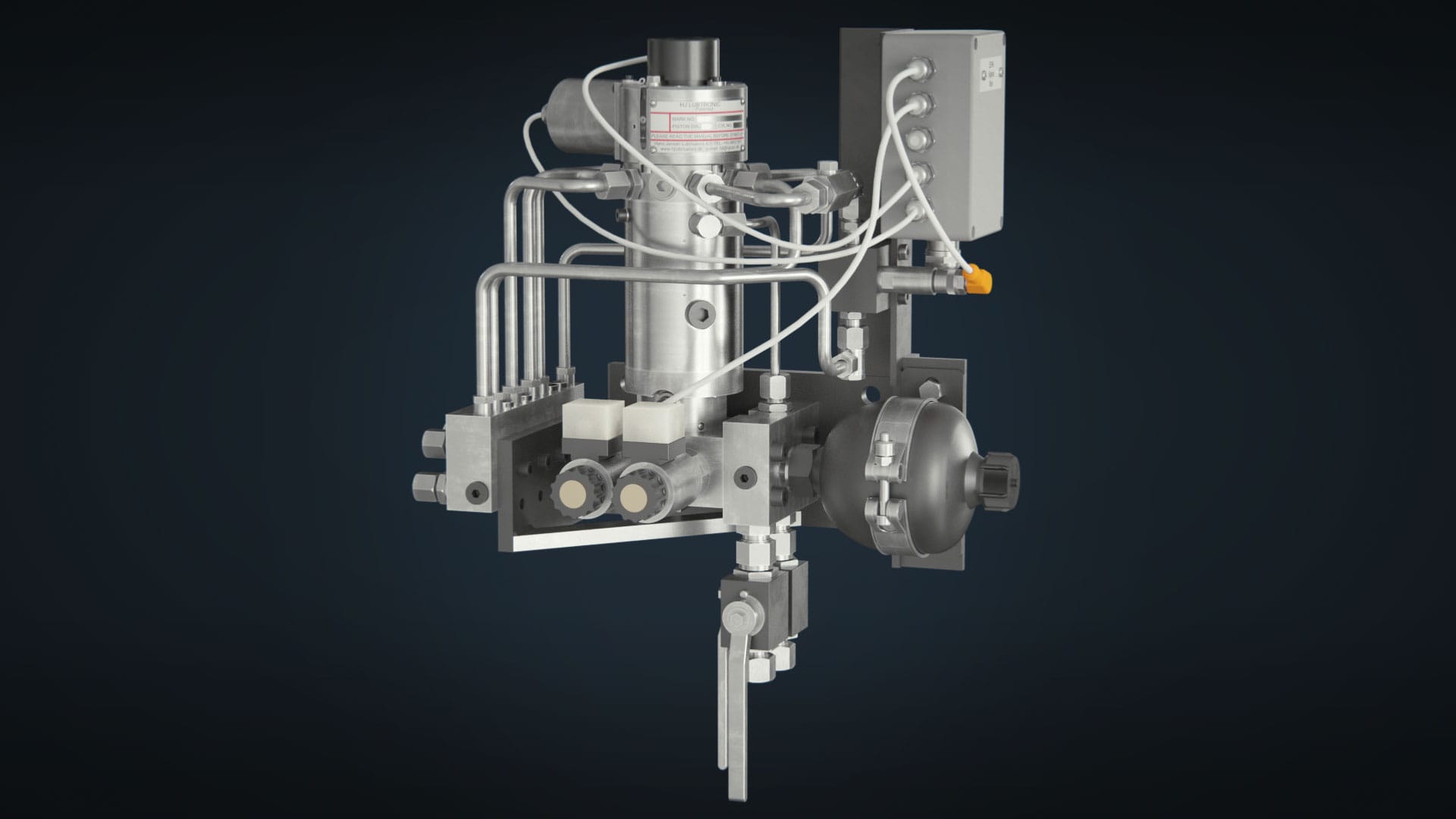

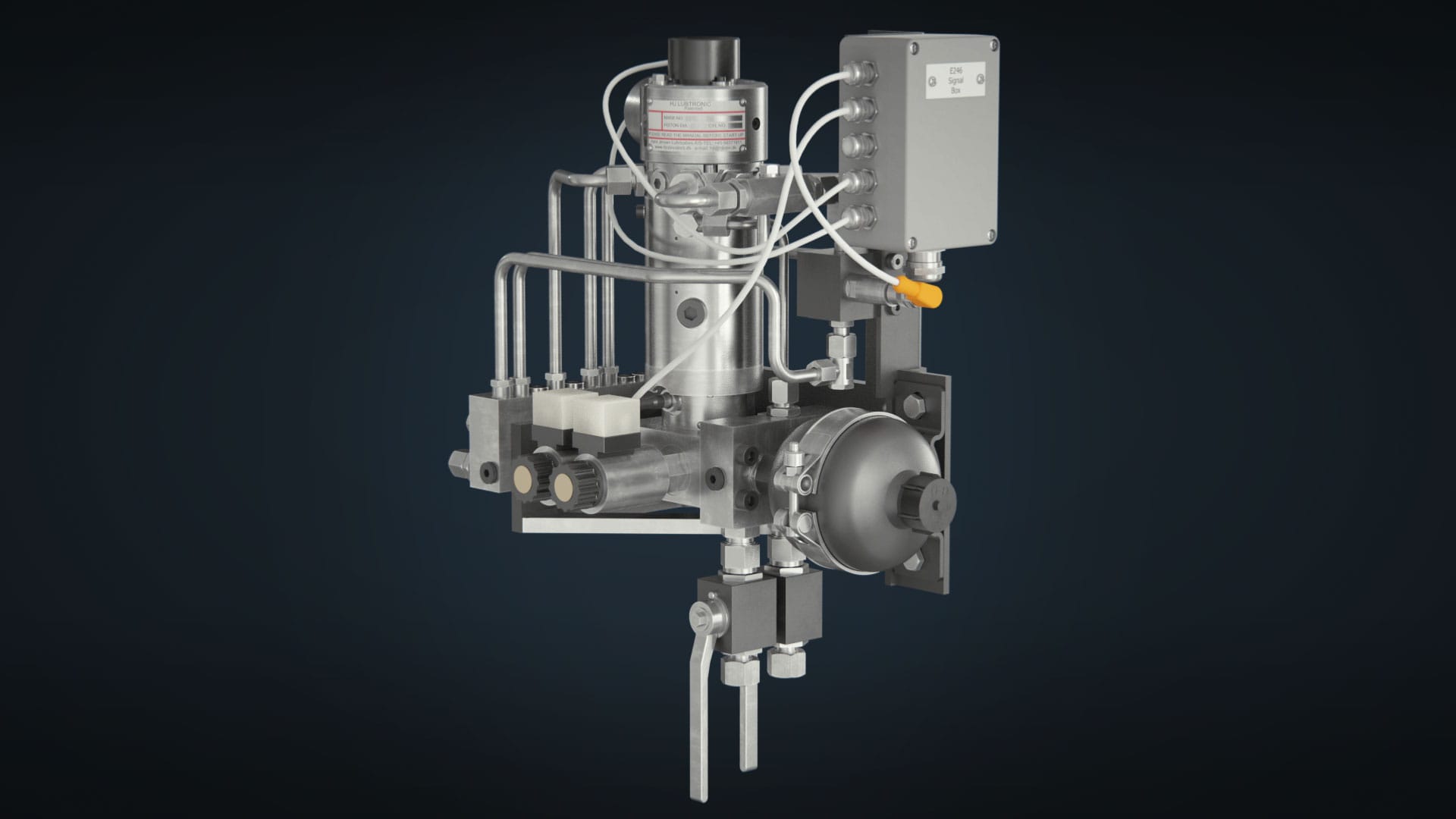

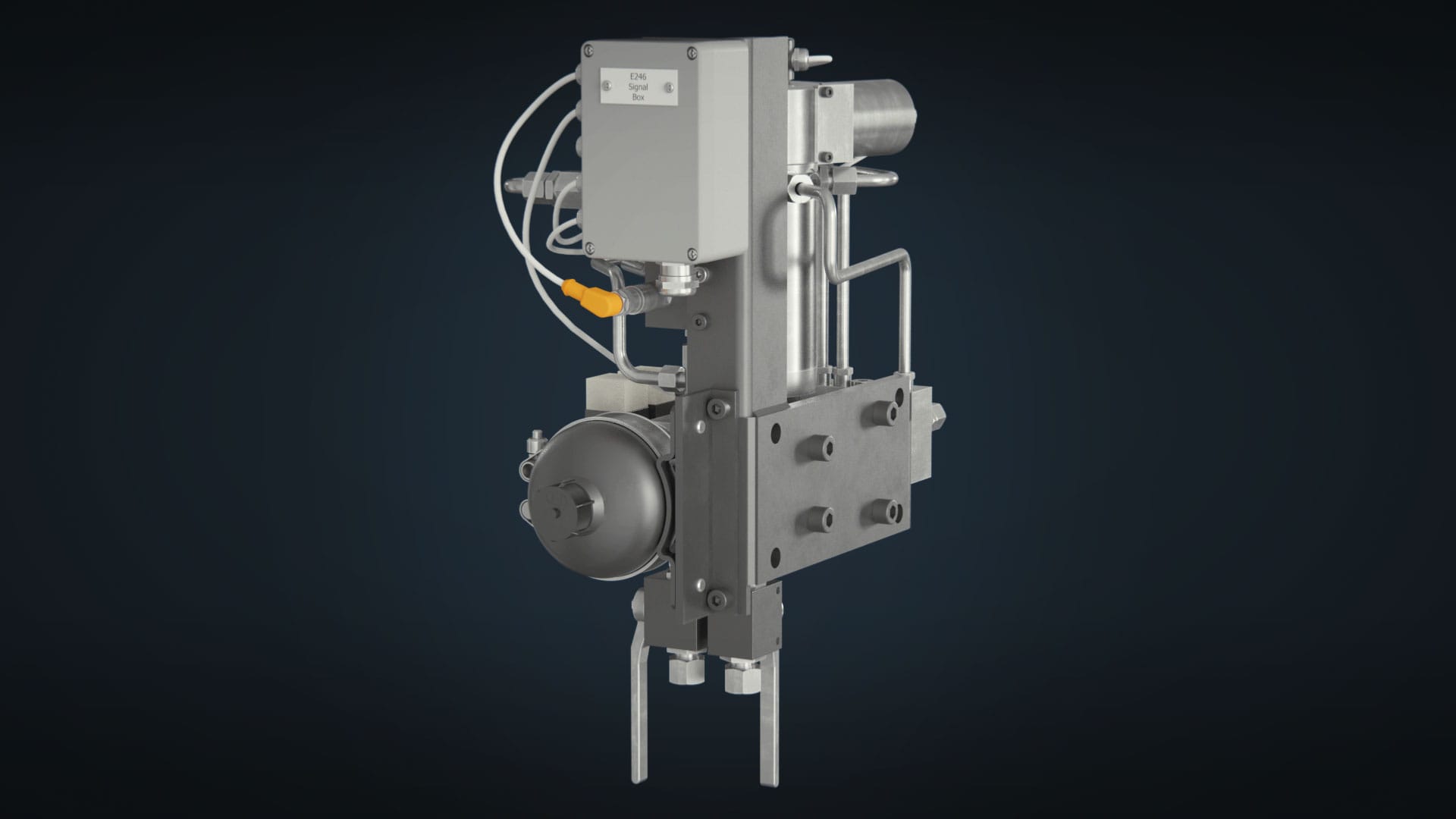

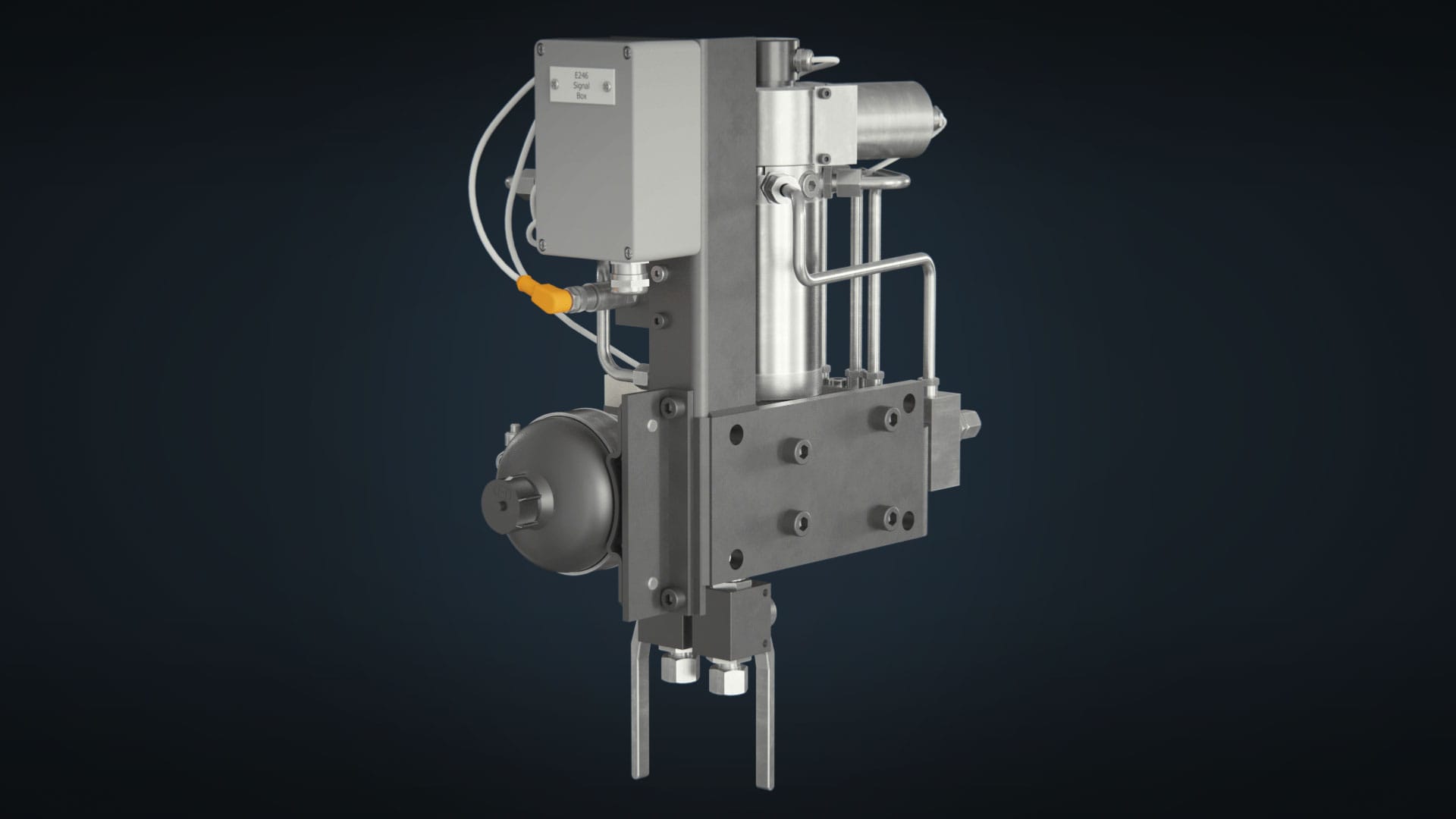

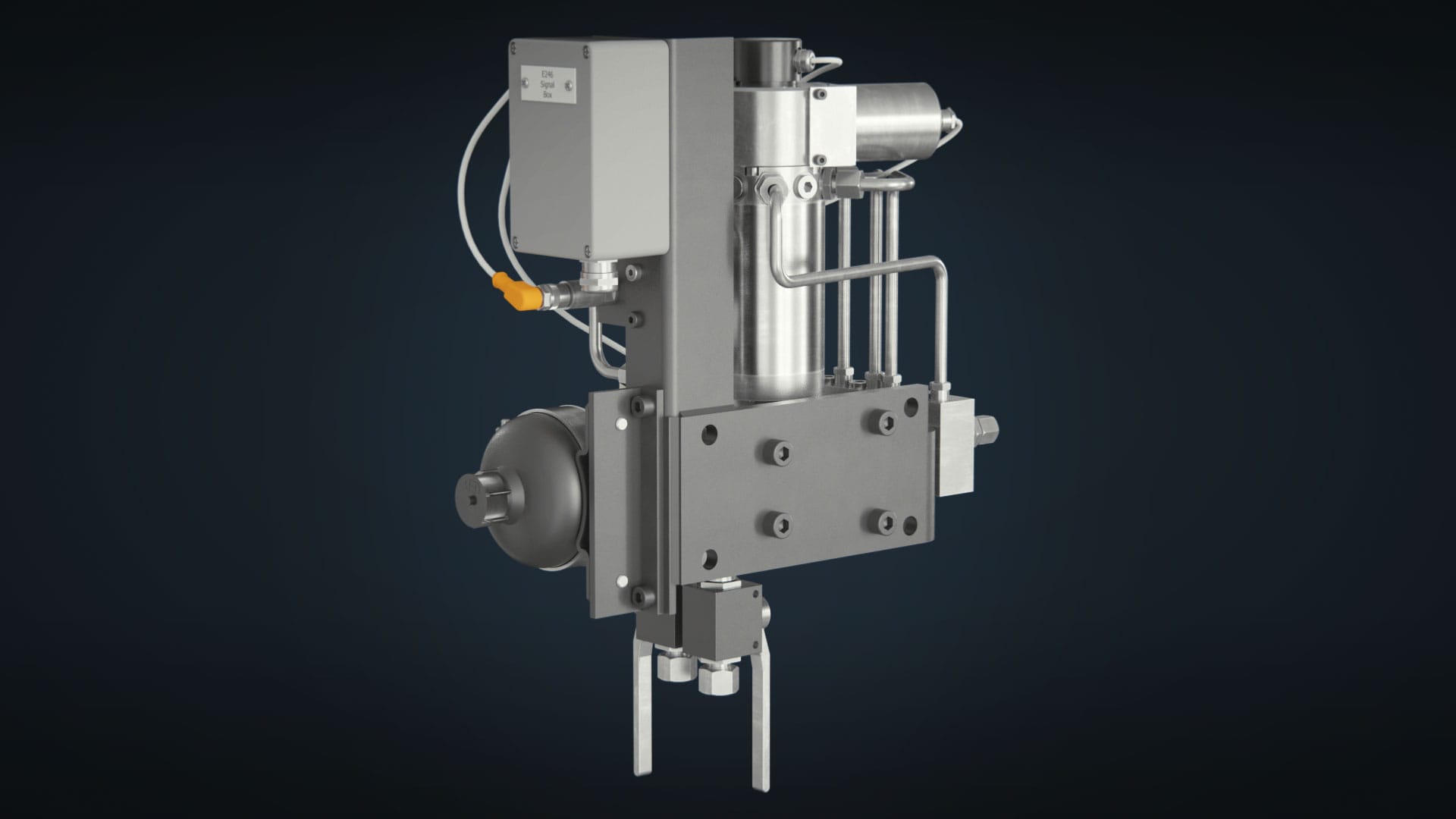

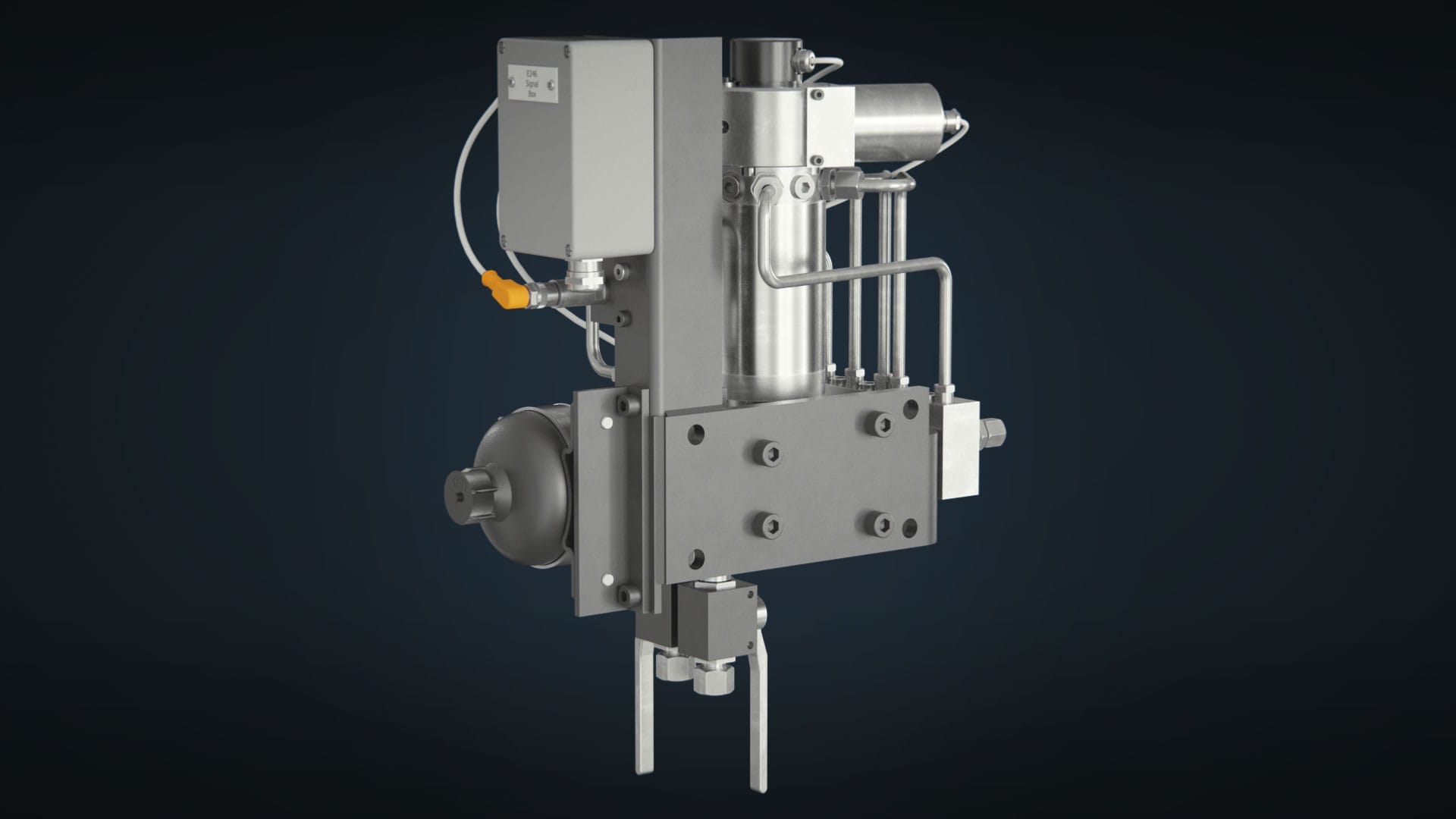

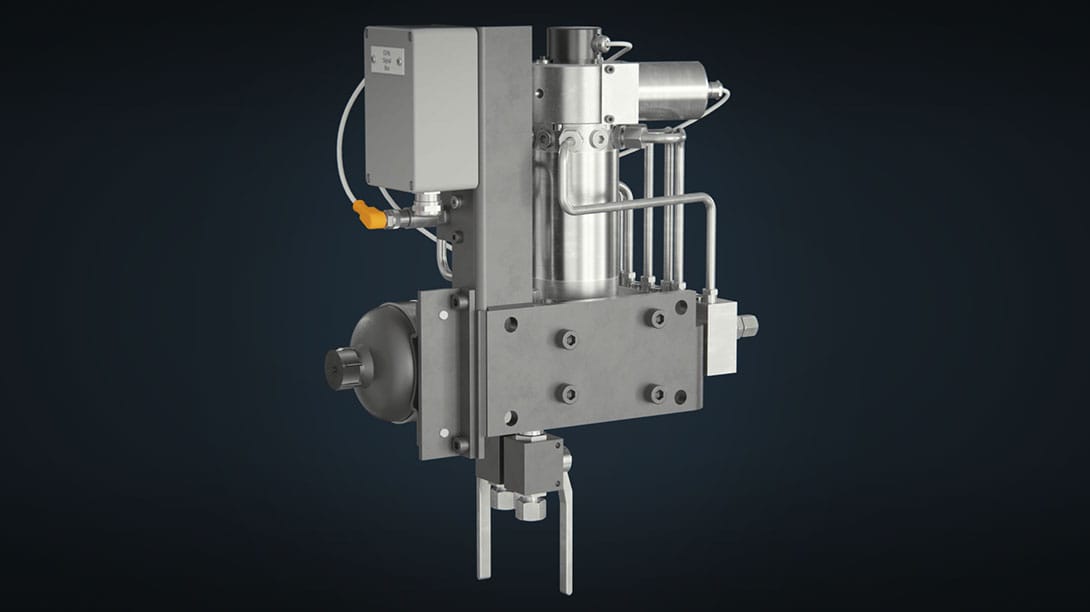

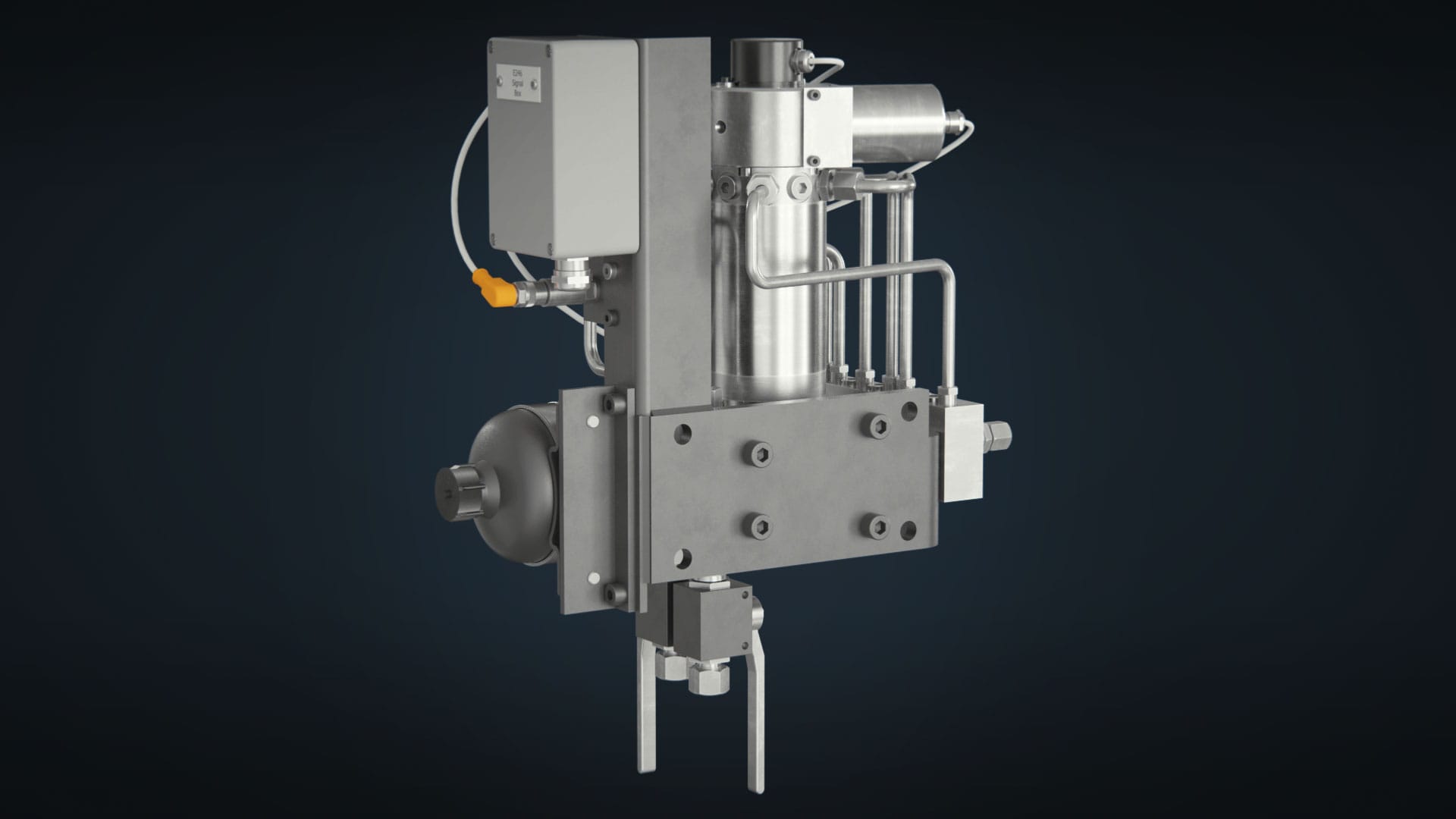

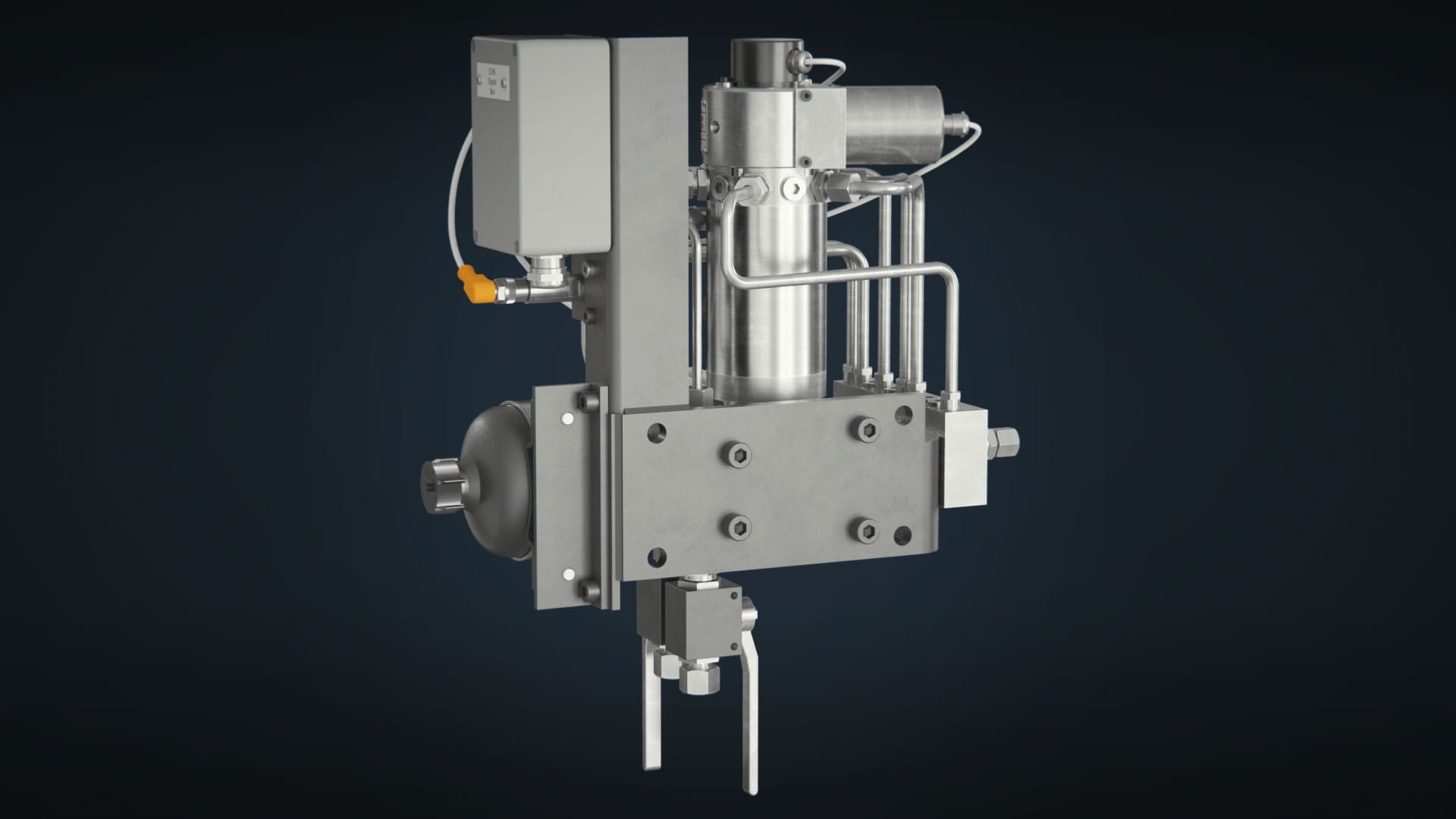

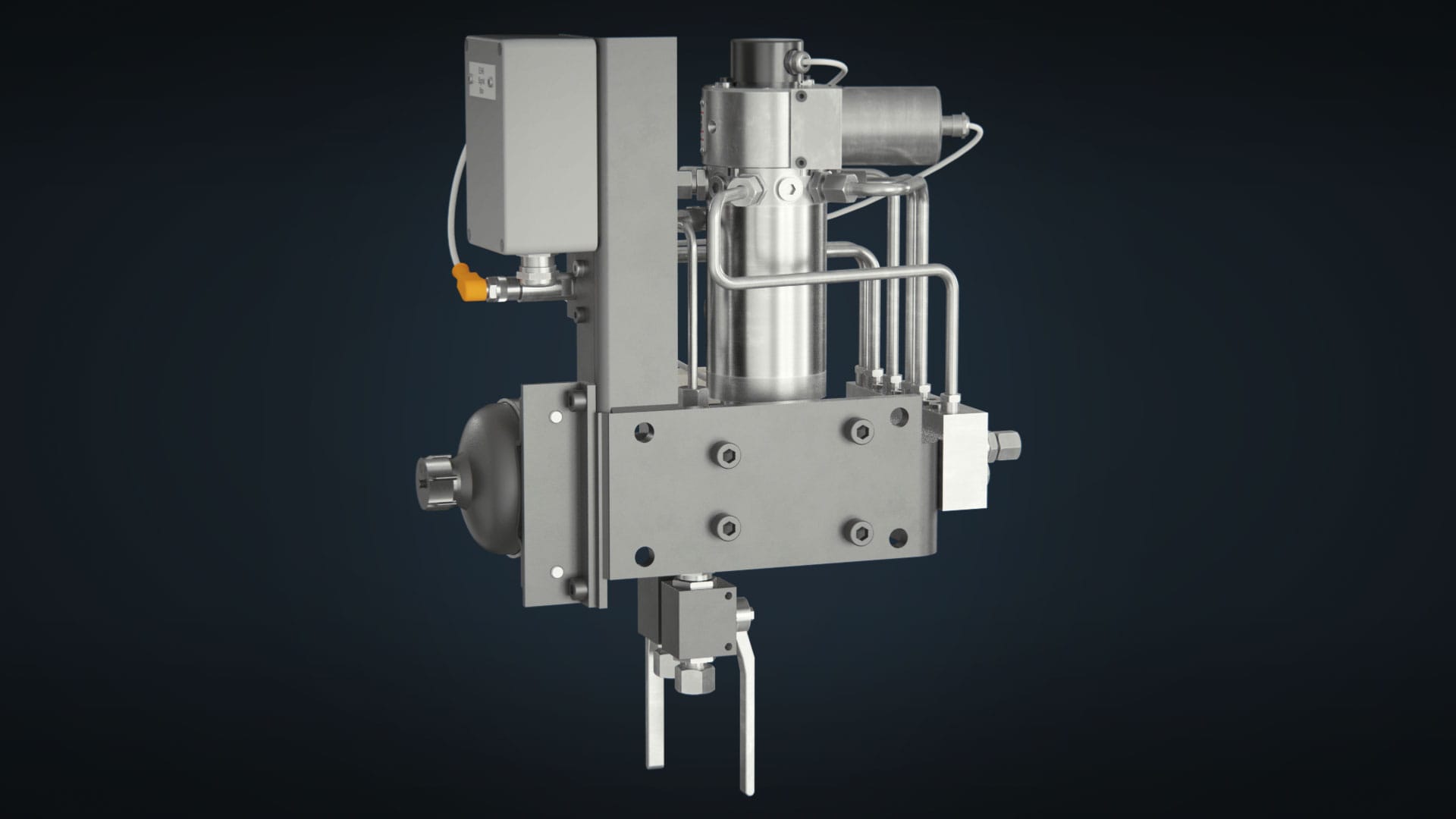

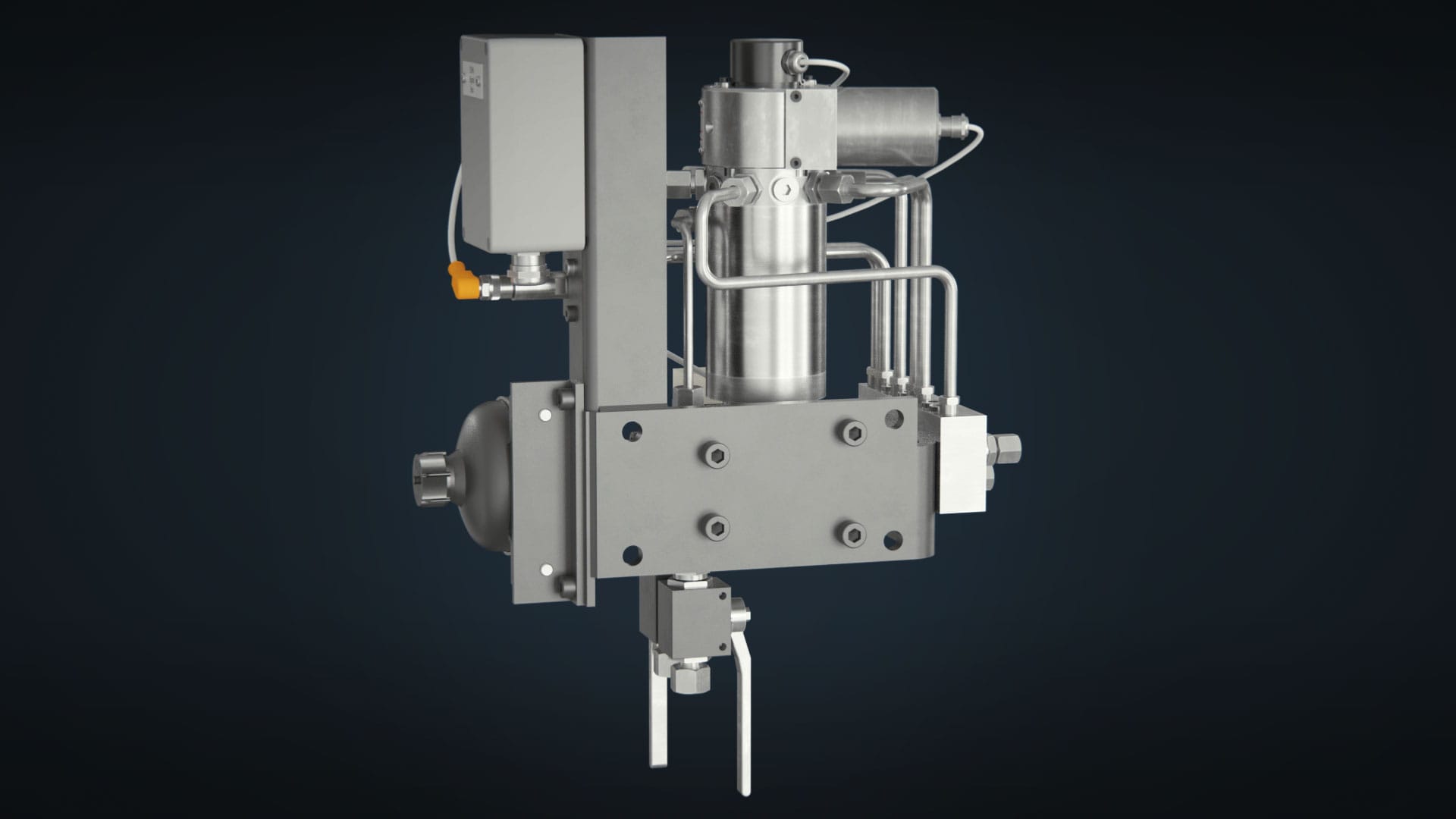

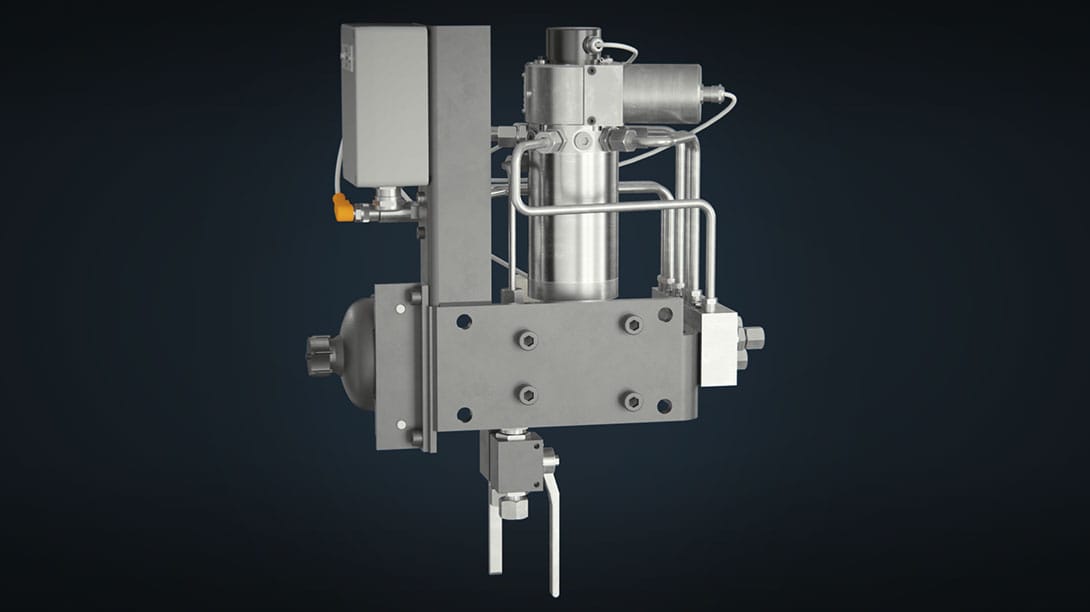

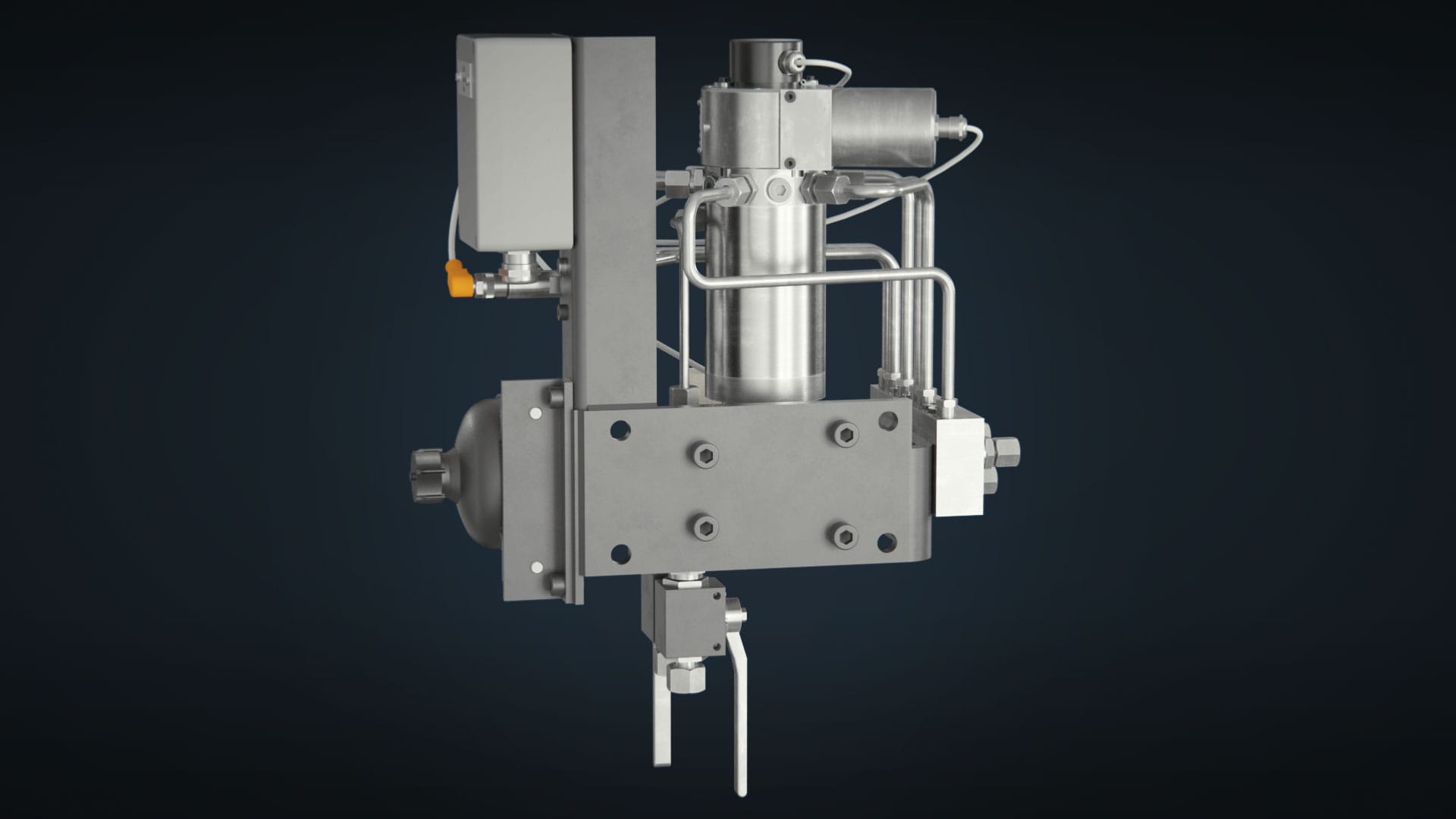

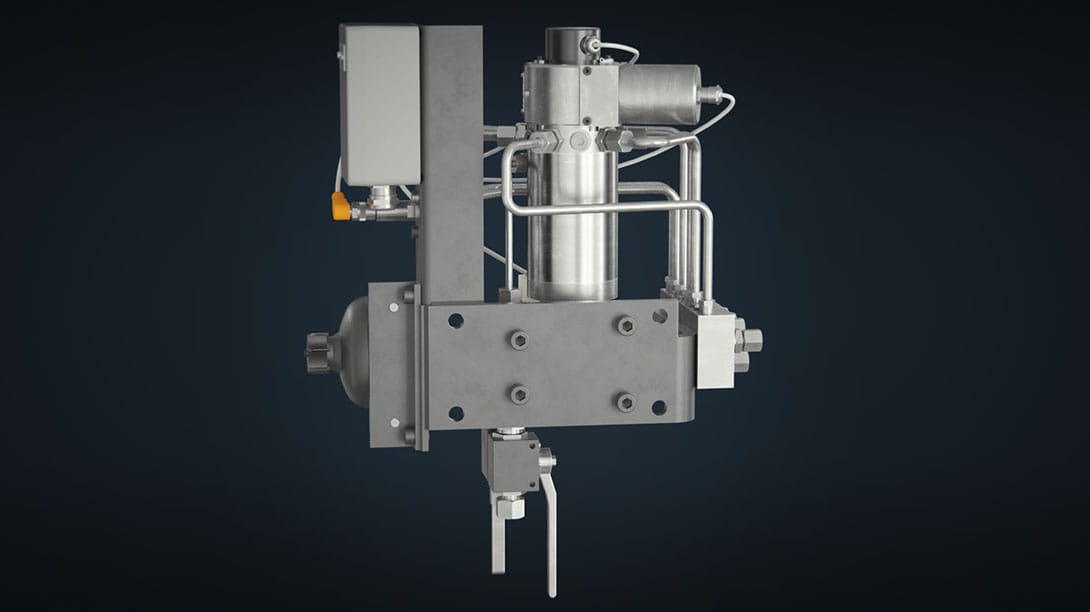

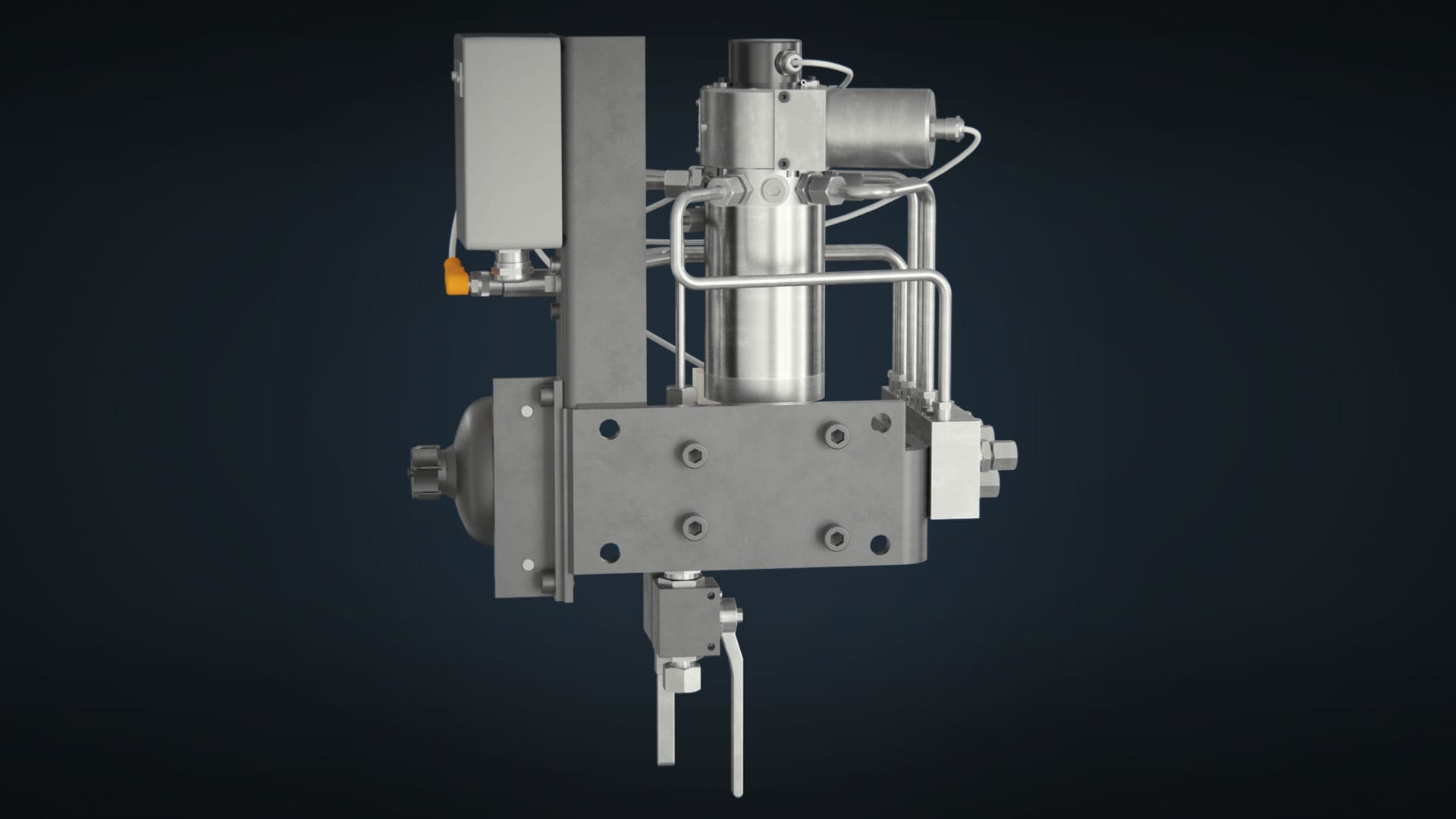

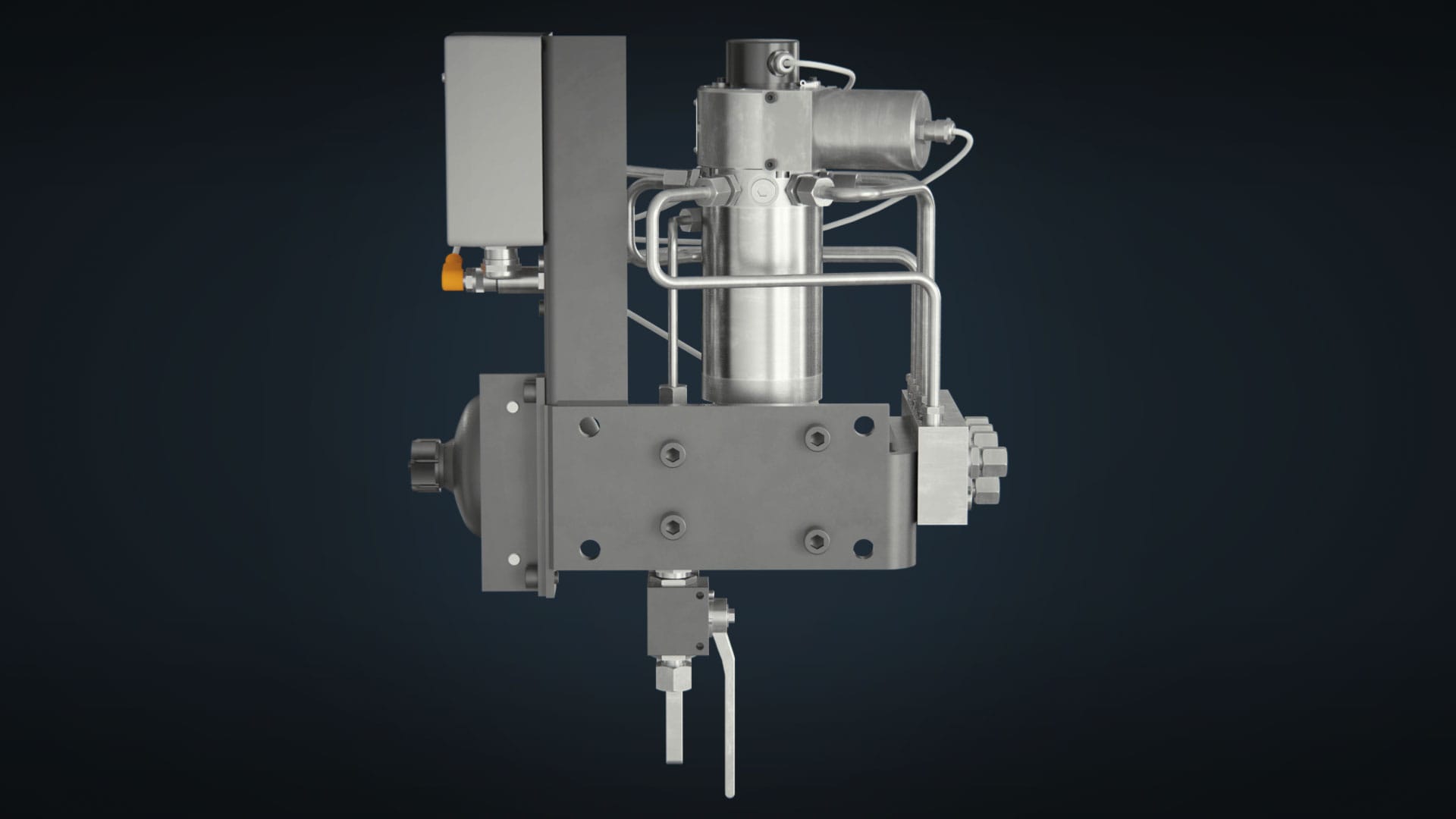

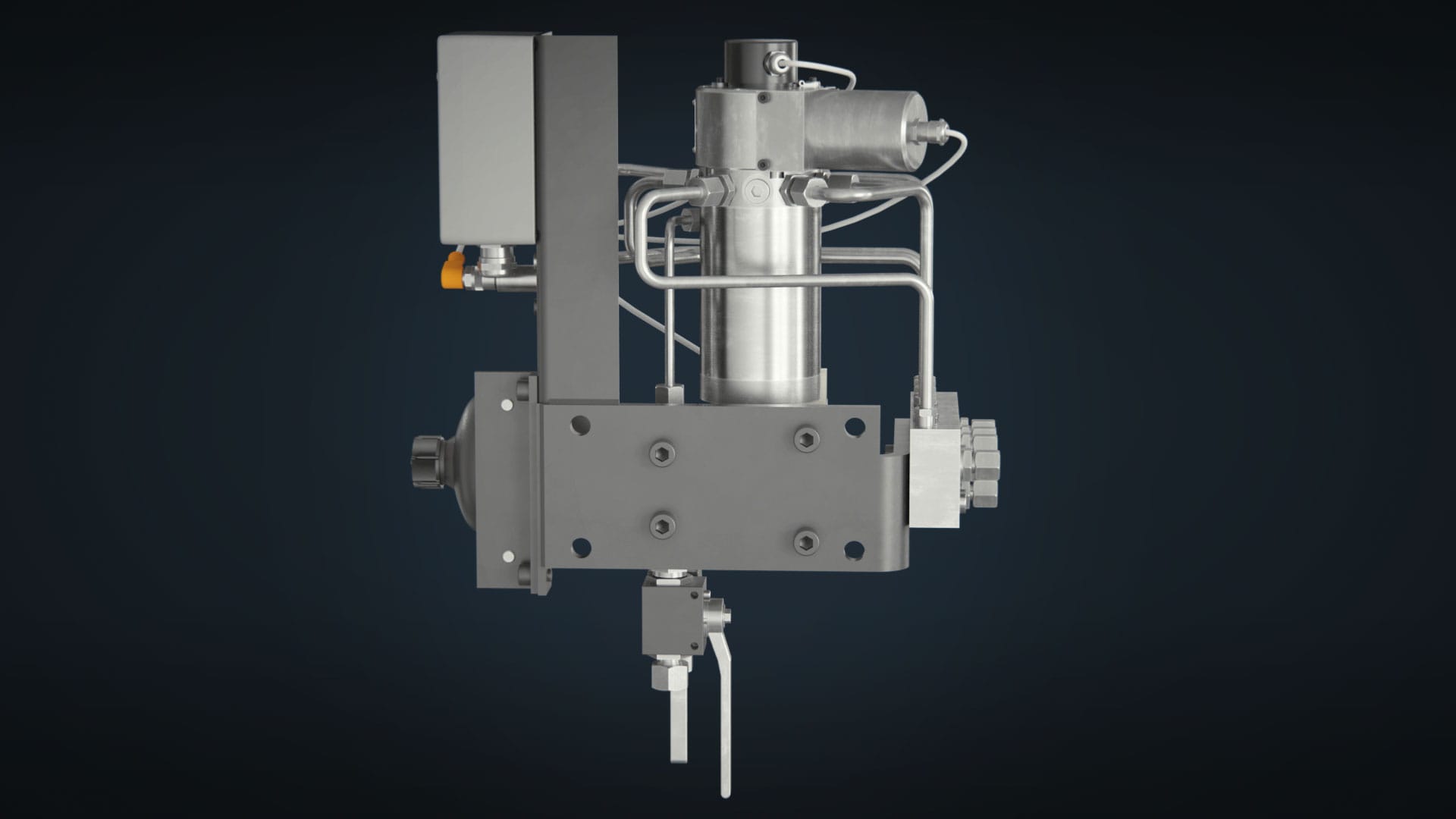

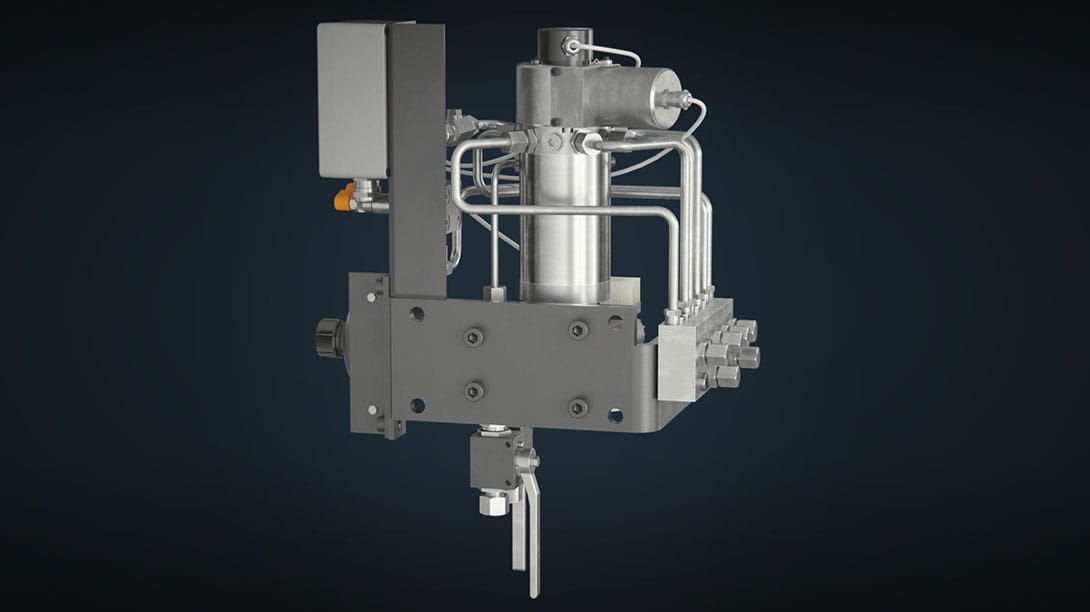

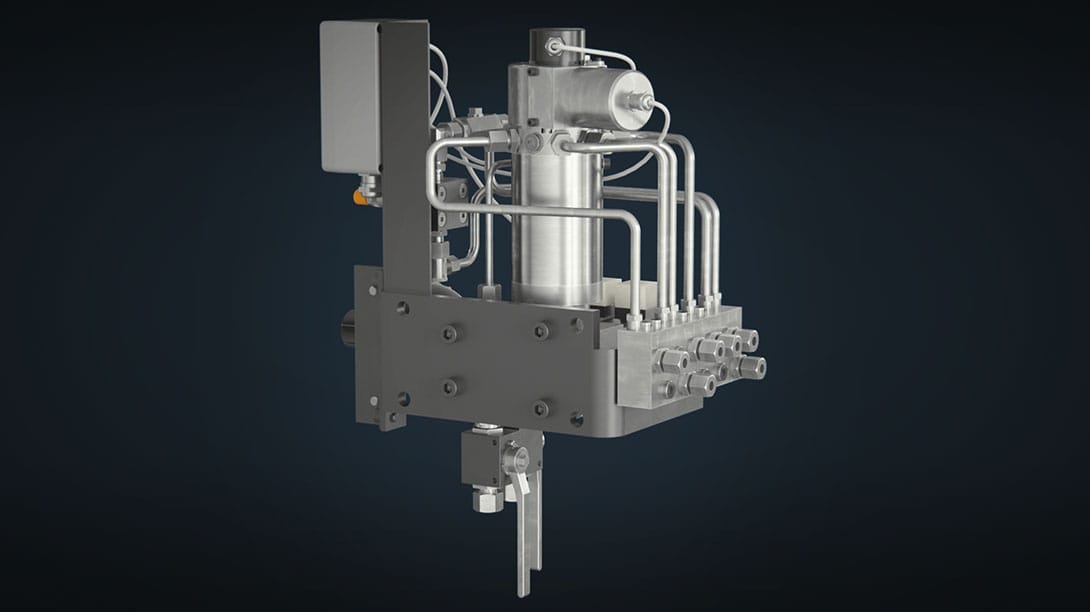

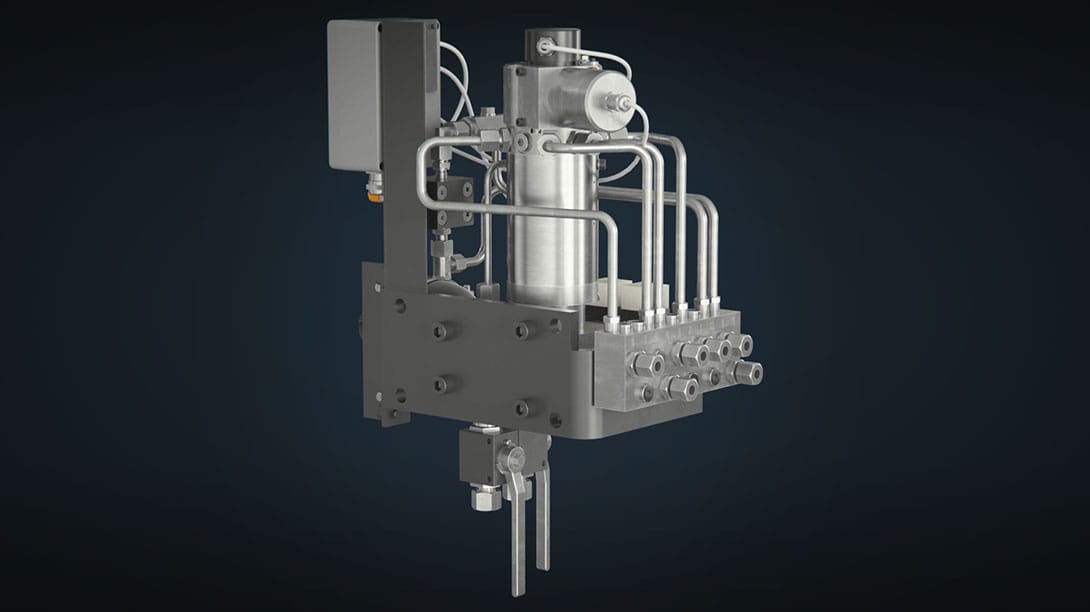

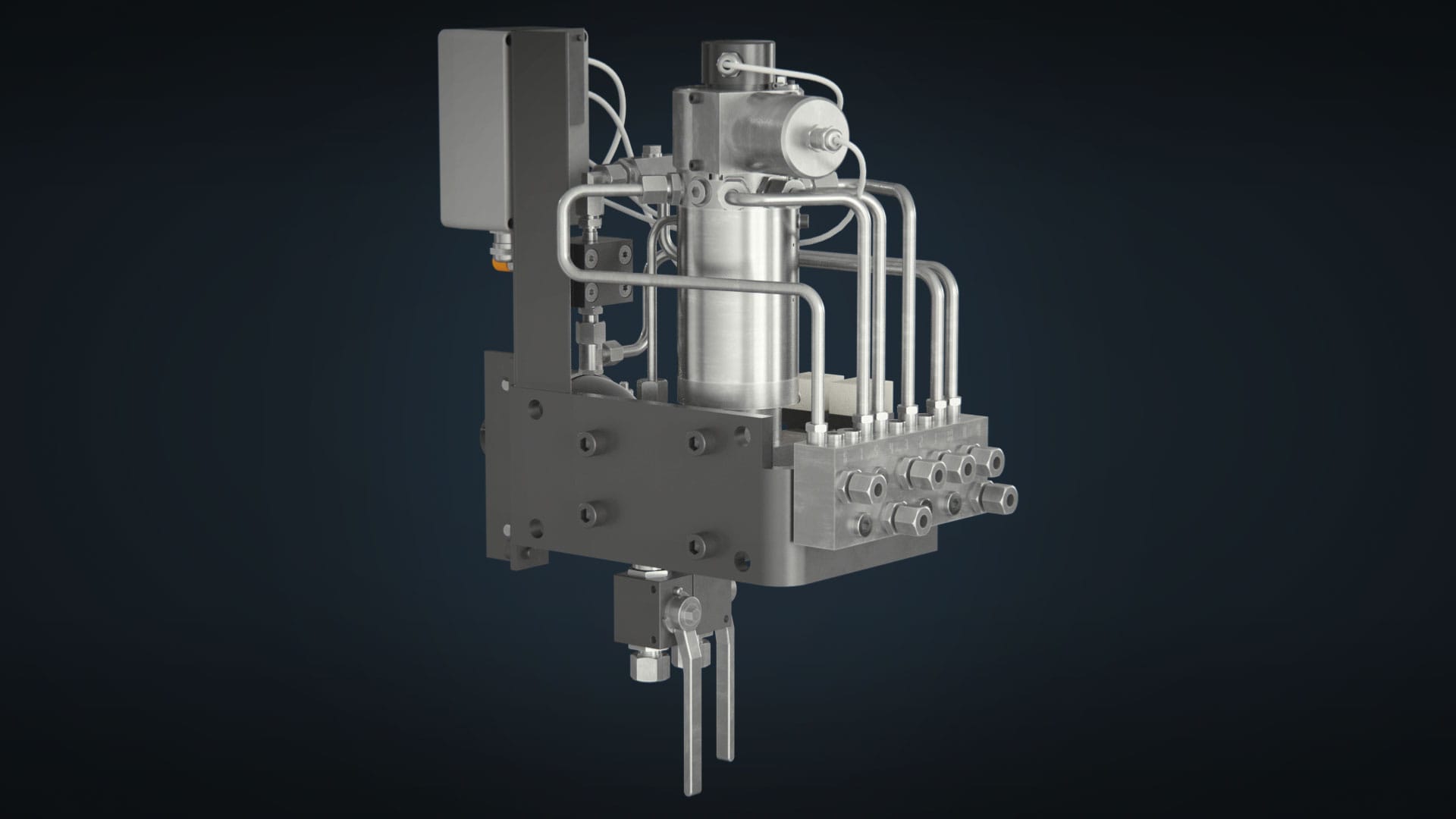

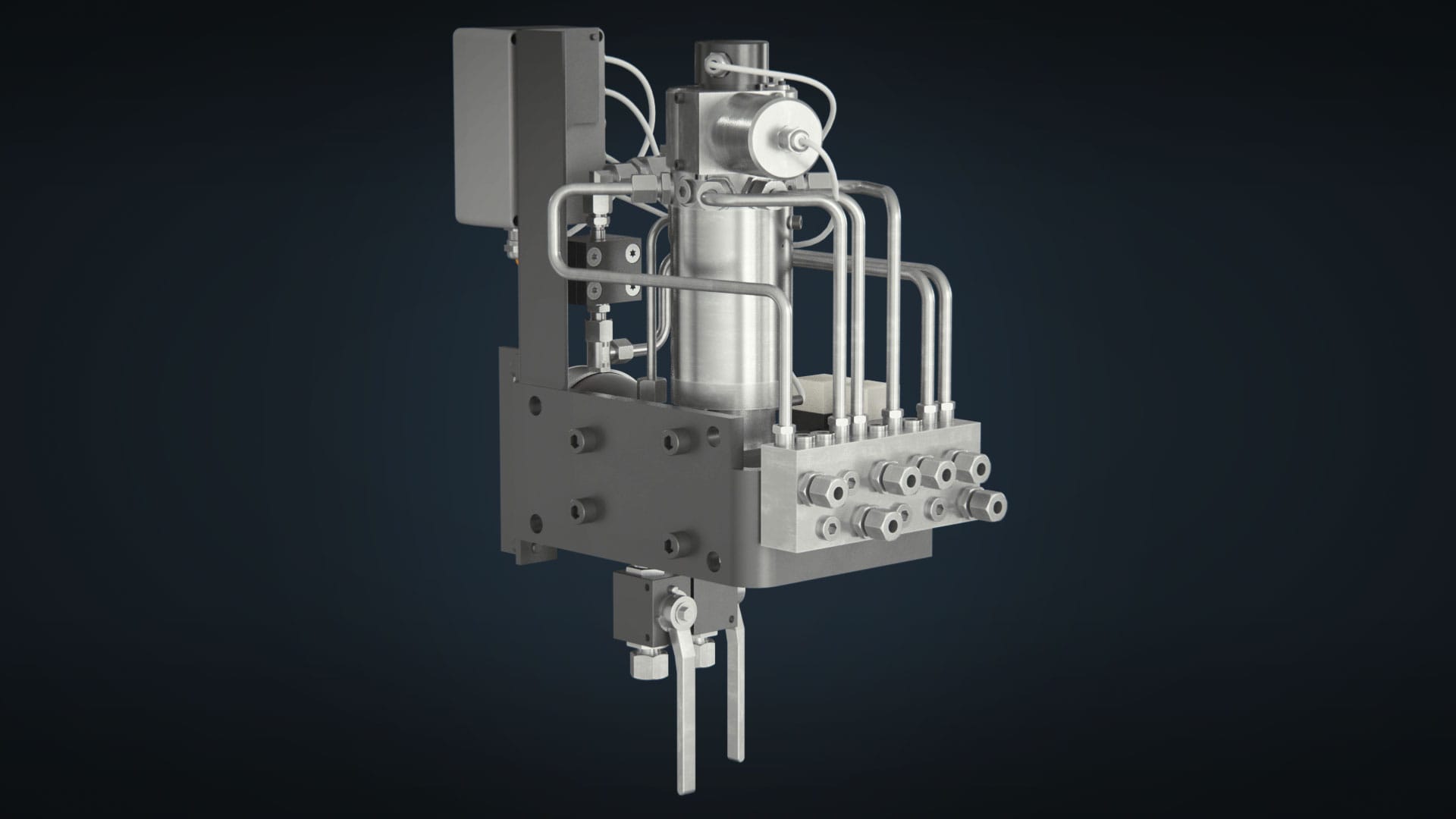

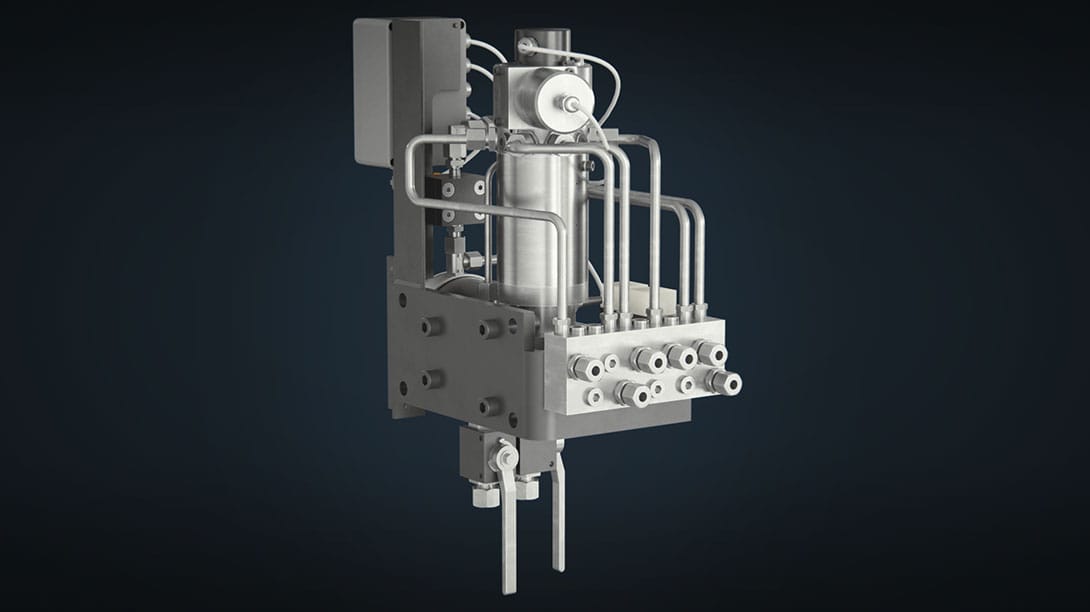

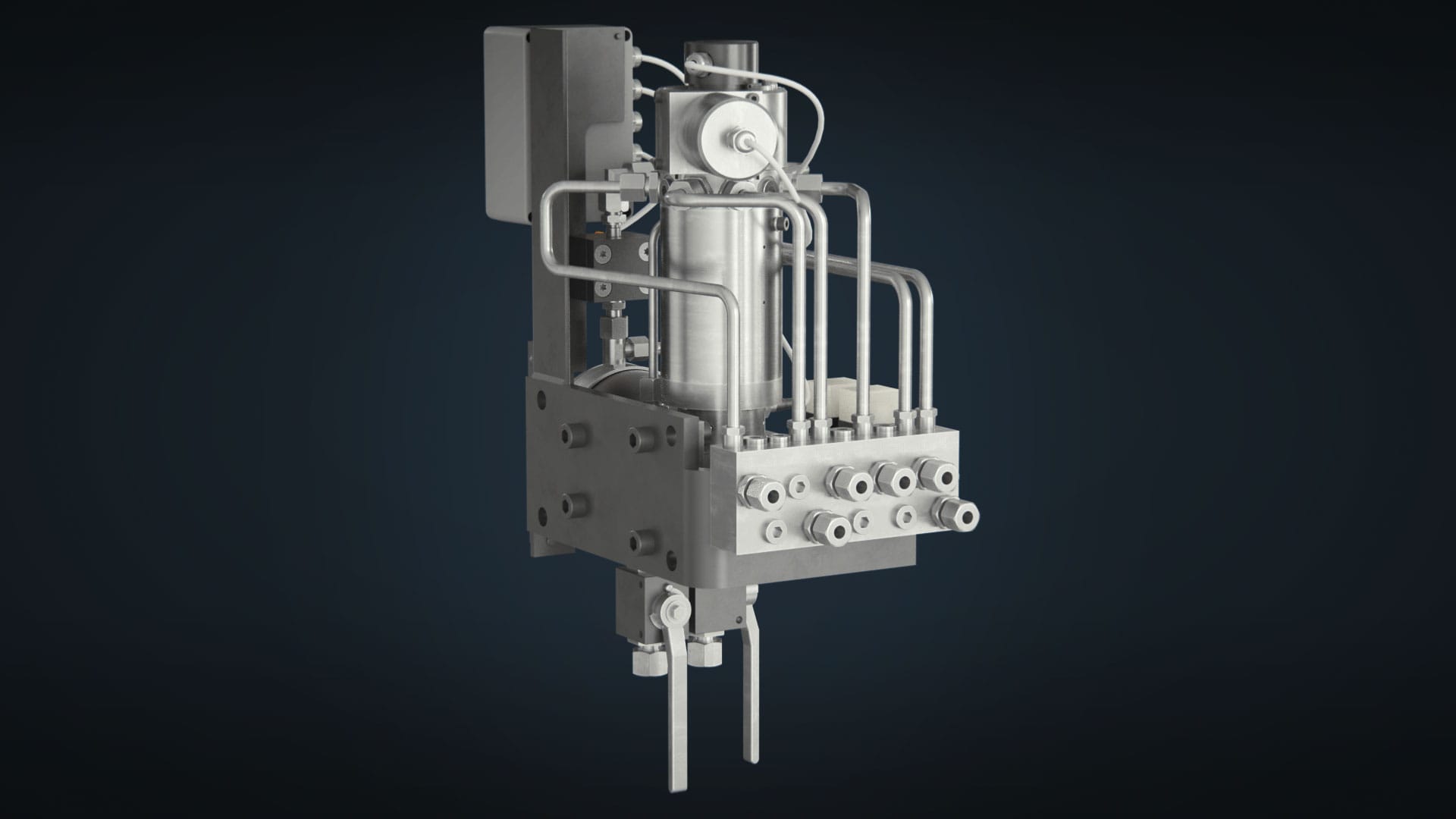

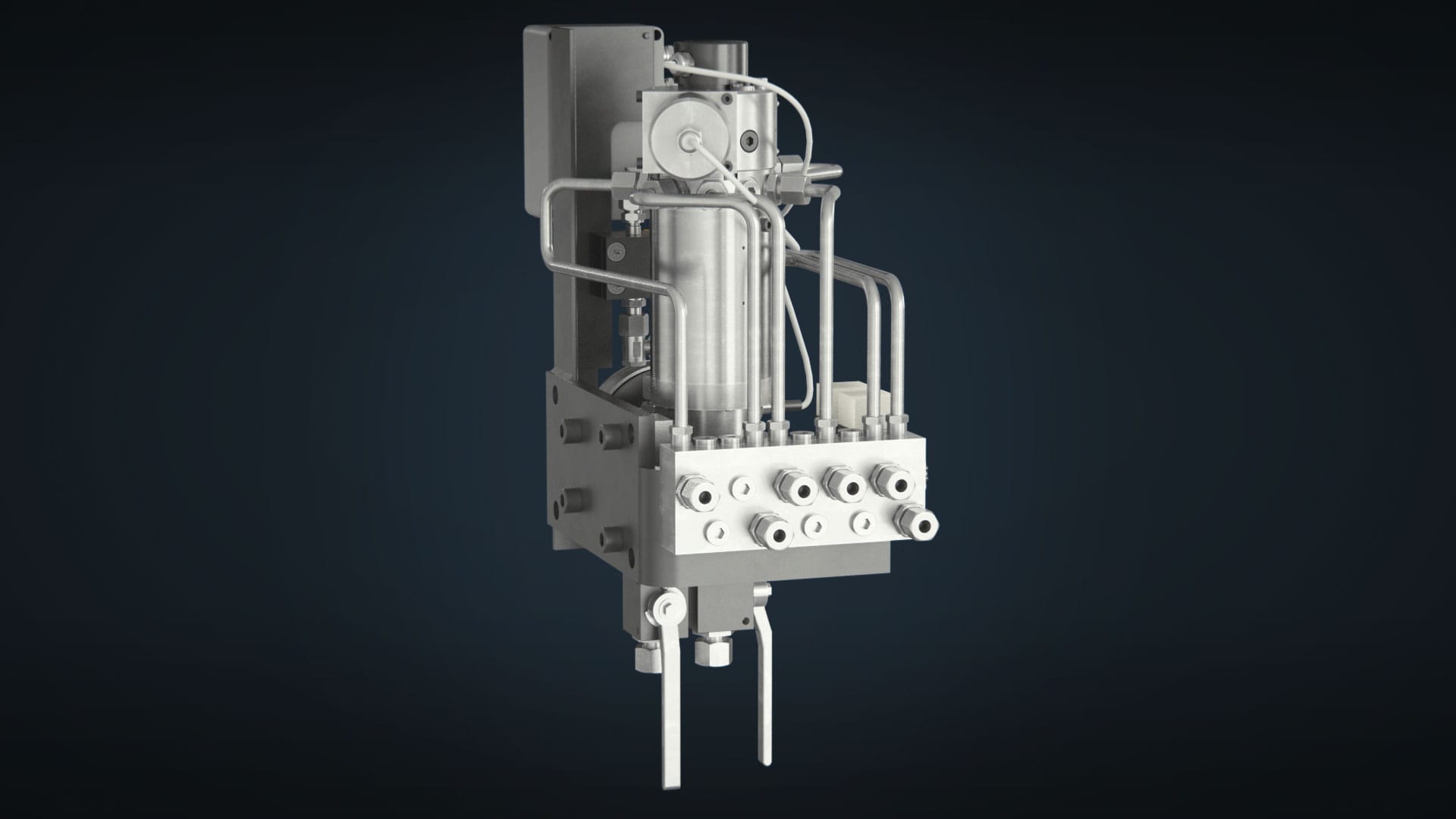

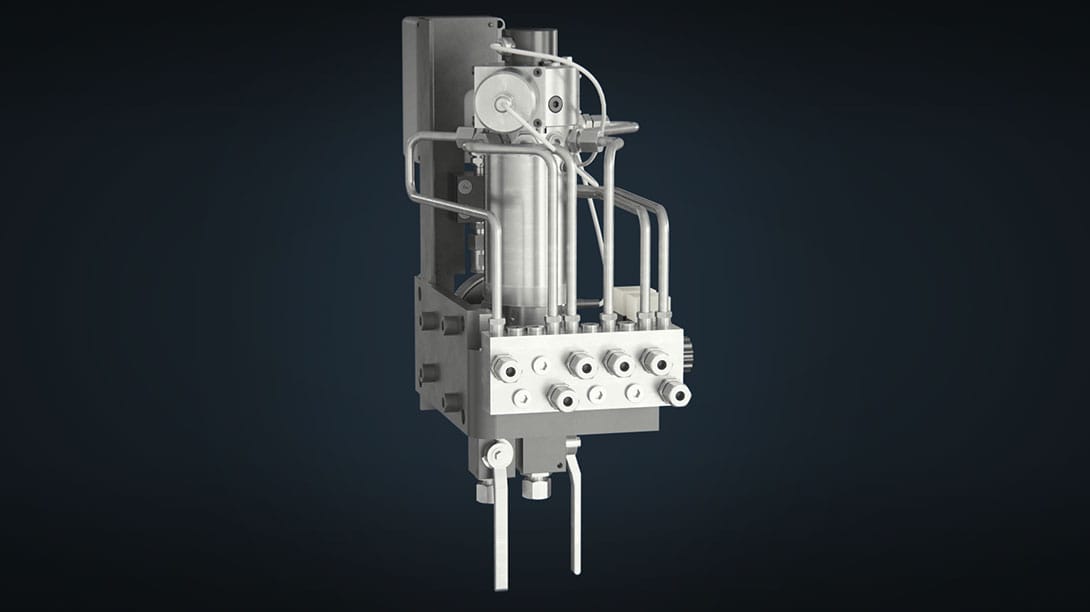

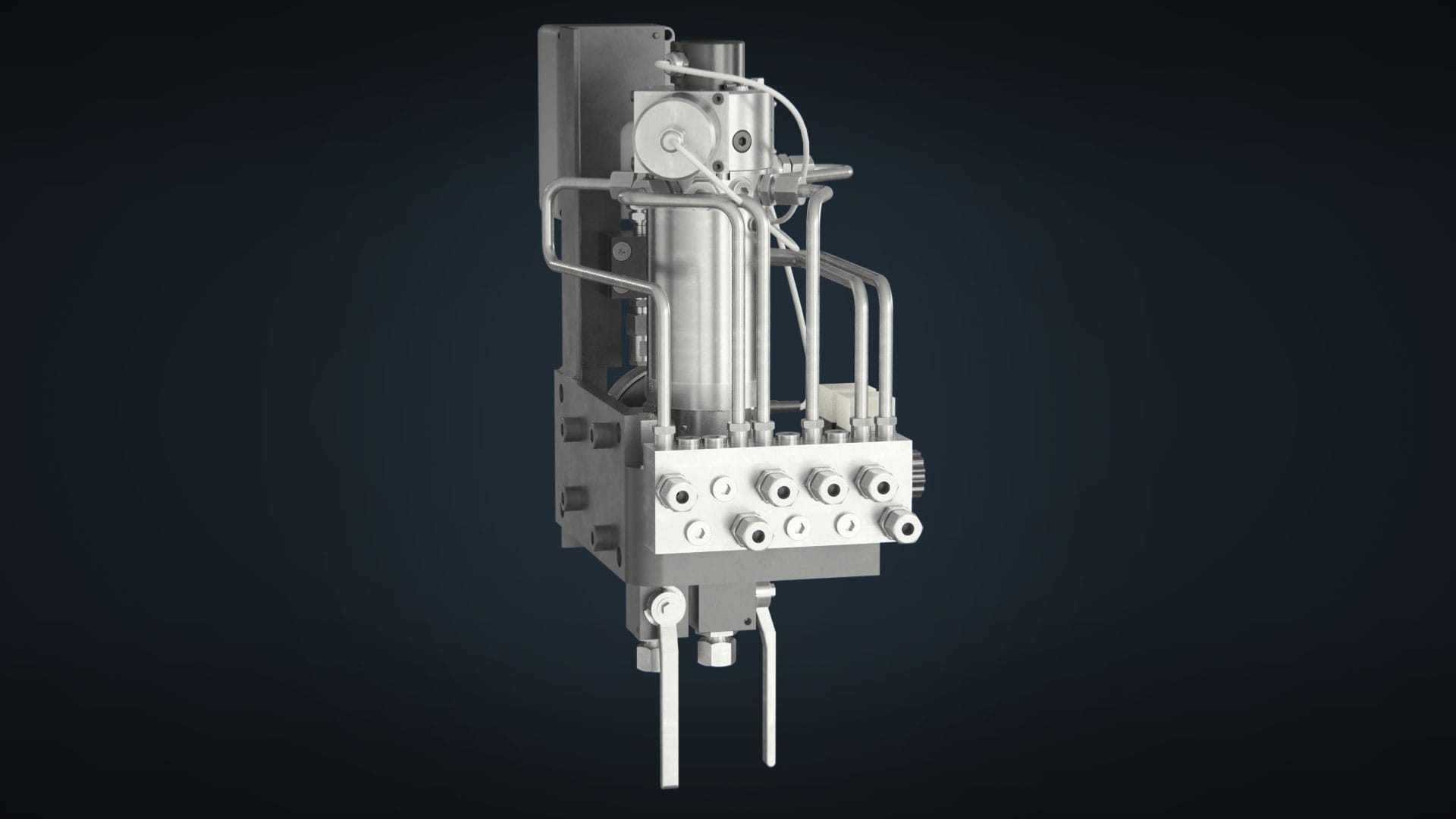

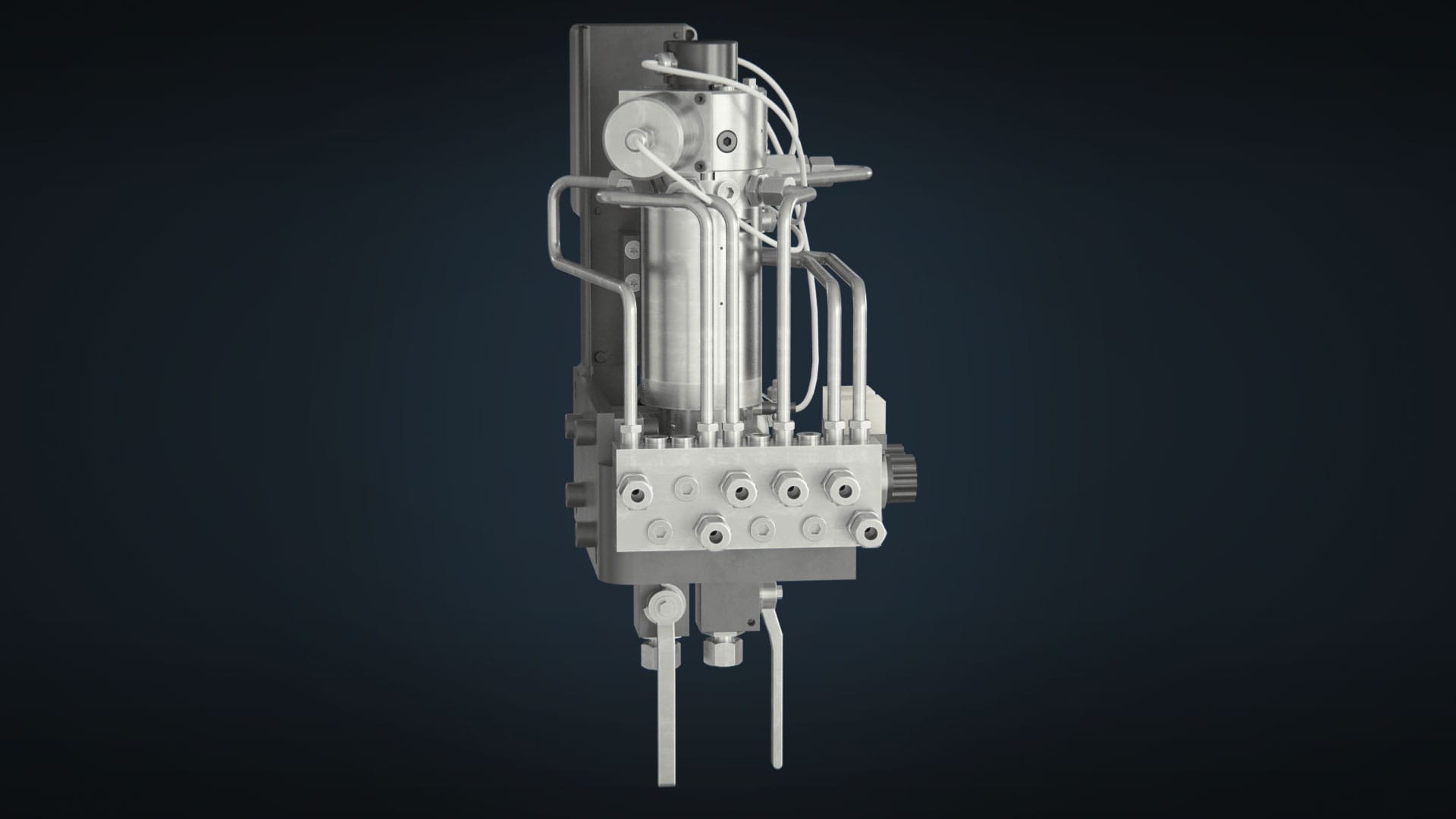

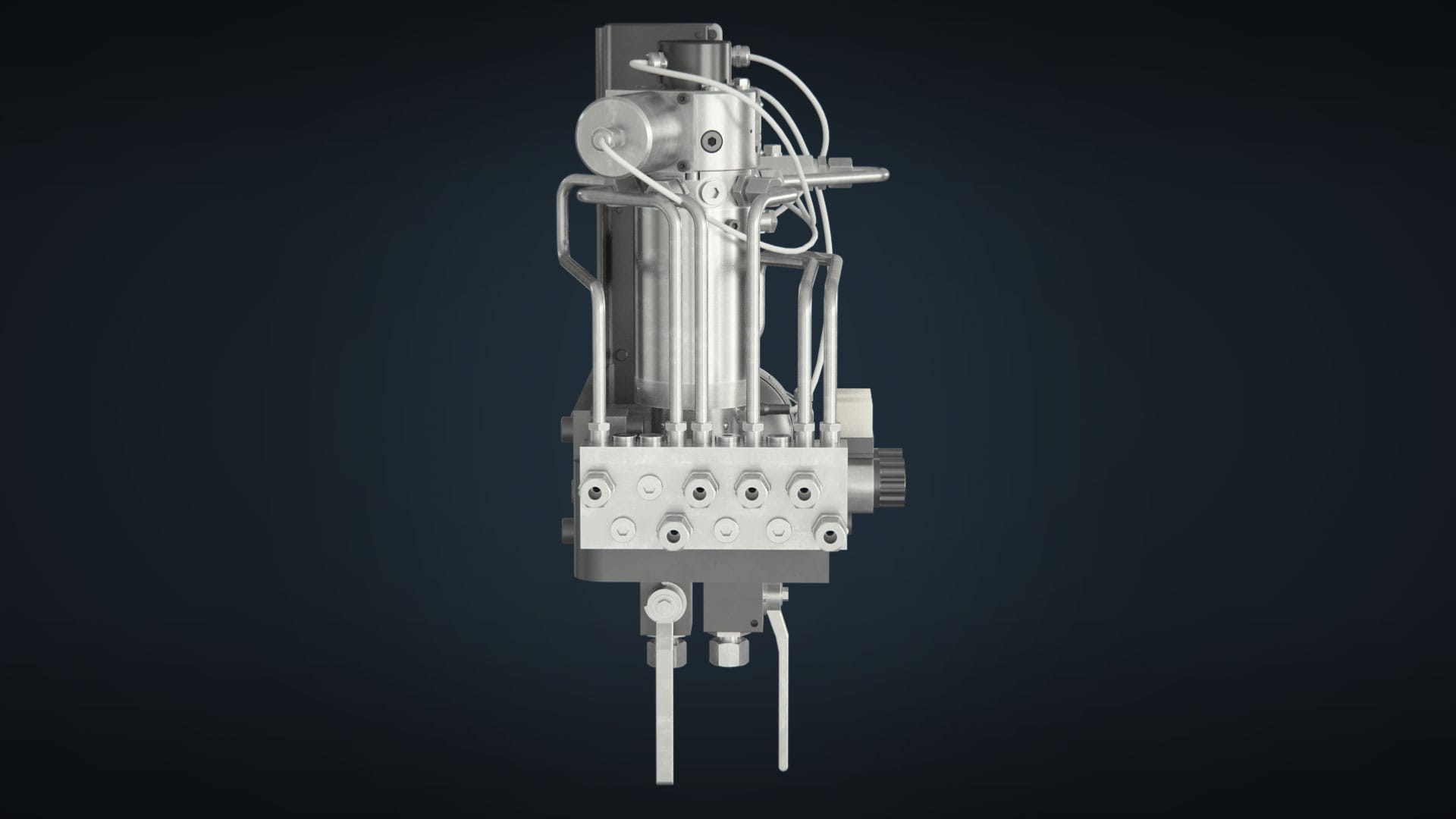

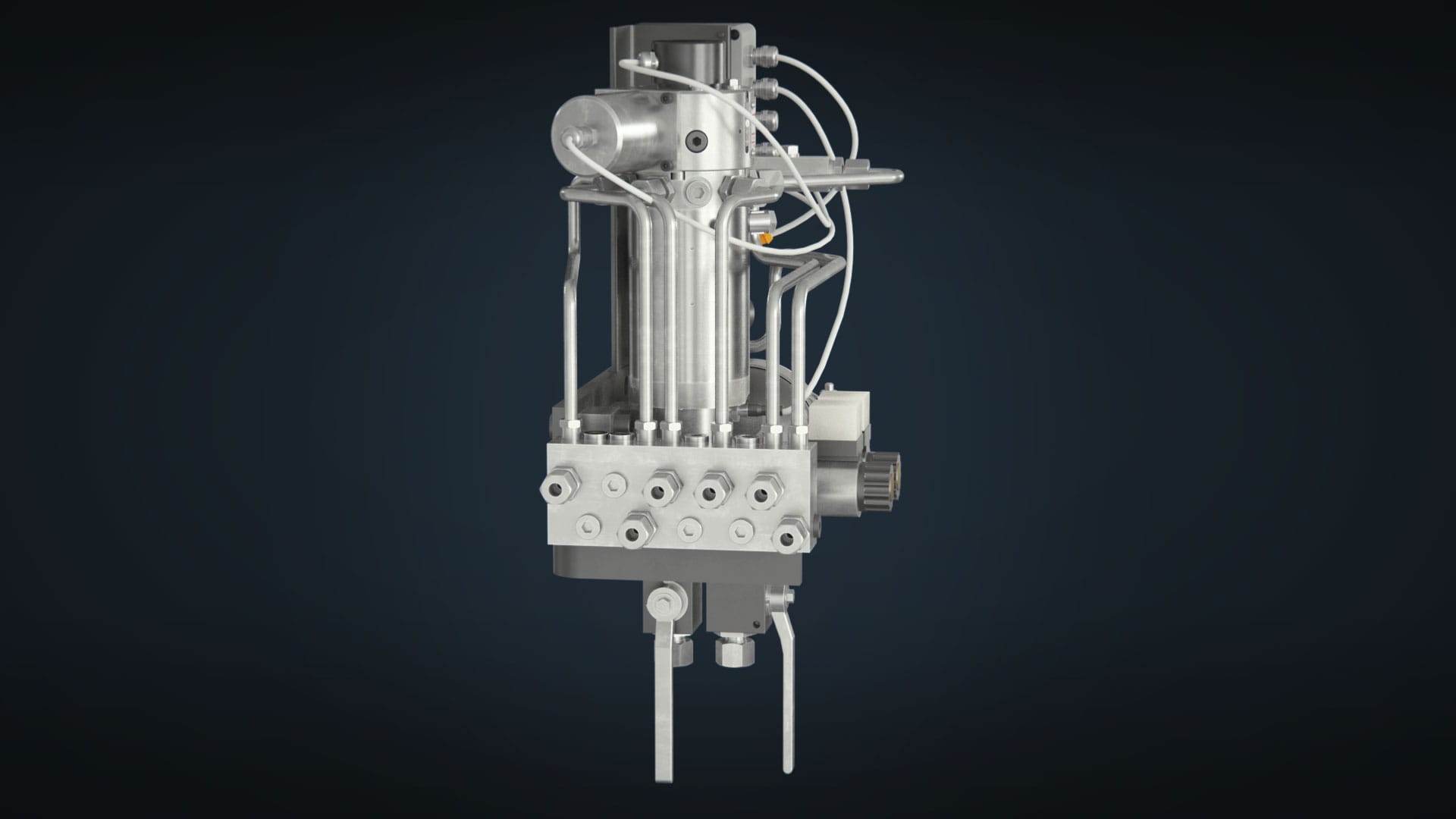

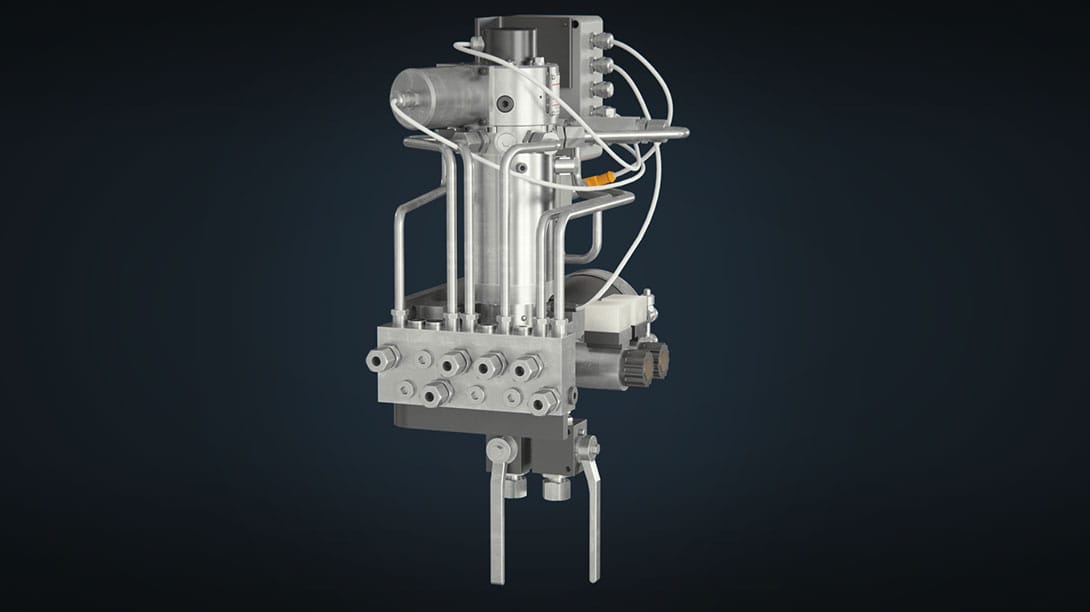

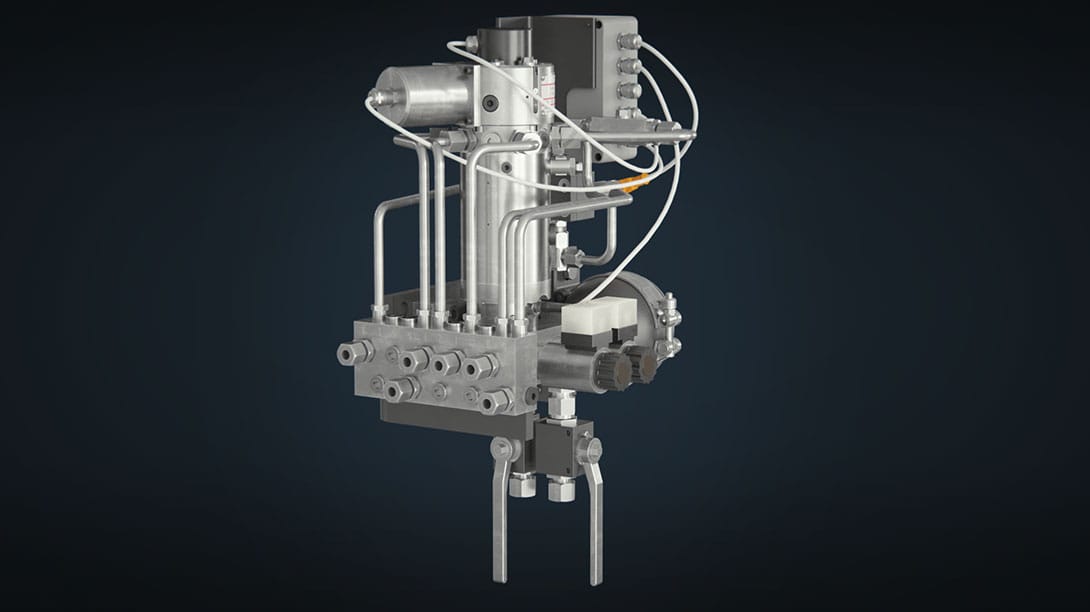

HJ LUBTRONIC

HJ Lubtronic is an electronic lubricator that adjusts feed rate according to ME load, BN number or sulphur content of the fuel oil.

This effectively reduces cylinder oil consumption and optimizes cylinder condition and engine reliability.

The system works on all engine types and designs.

- Oil injection in every piston stroke

- Atomizing cylinder oil into the combustion chamber

- Automatic load or sulphur dependent feed rate regulation

- Automatic Cleaning Sequence algorithm (patented technology)

- Delta-Timing algorithm ensures lubrication both into the ring pack and liner

- Sulphur-, load- and BN-dependent algorithms

- Possibility for online monitoring and preventive alarms

-

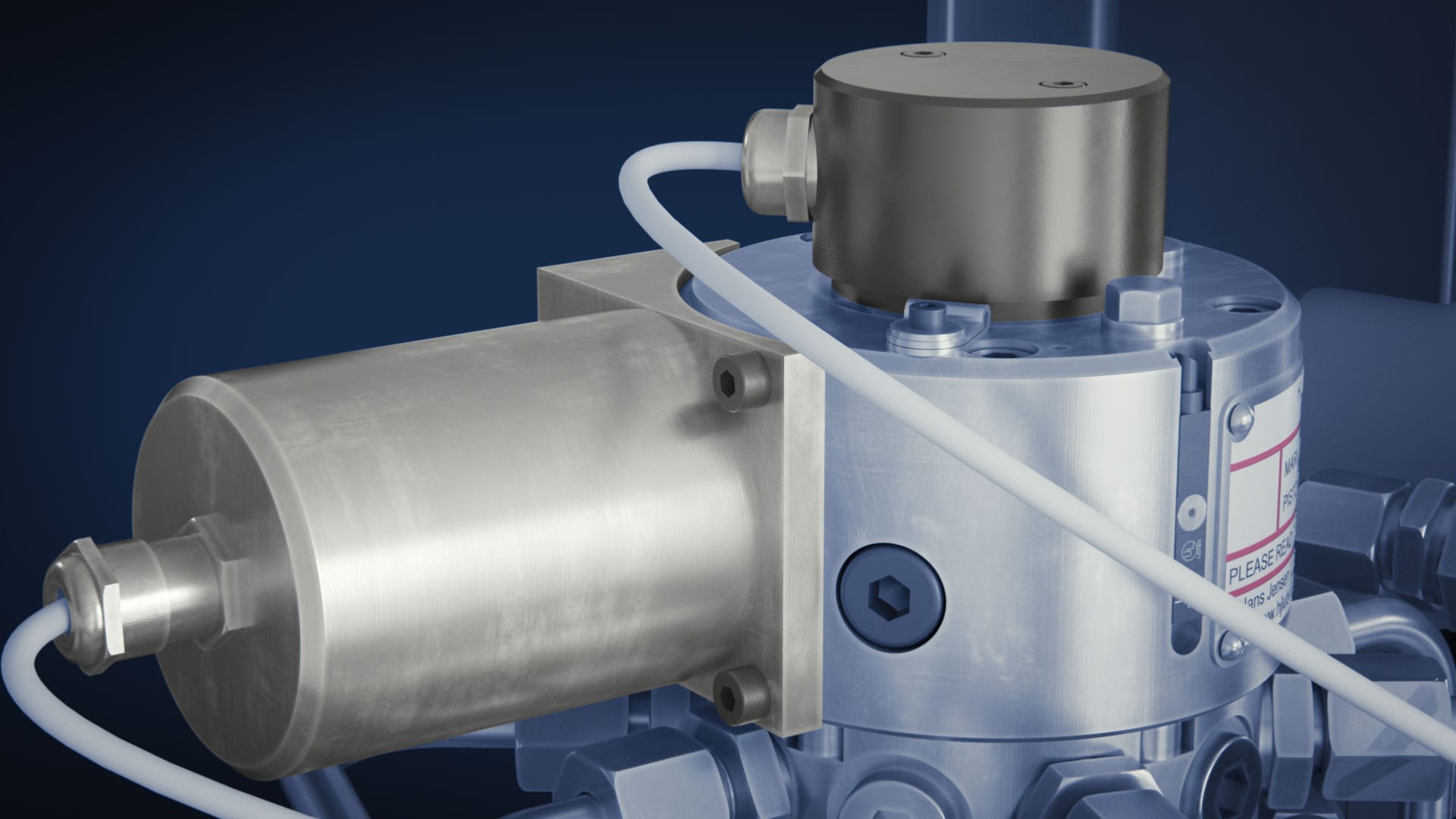

DC motor and potentiometer

The quantity of oil delivered from the lubricator is adjusted by the DC motor, by changing the stroke-setting.

The DC motor adjusts the stroke-setting and a high precision potentiometer measures the given setting.

The stroke length can be adjusted from 2 mm to 9 mm, enabling a volumetric dosing that matches the operating parameters of the engine.

-

Over pressure sensor

The over pressure sensor is added in order to protect the pressurized parts in the piping system. An alarm is generated if the sensor registers a pressure of 130 bars and above.

If an alarm is activated it means an injection valve is blocked and the system must be checked.

-

Flow meter

The flow meter measures at one of the lube points. The oil is delivered from one of the outlet pipes at the lubricator and flows through a magnet filter. After the magnet filter the oil runs through the flow meter. If the measured flow does not correspond with the stroke settings, first a warning, then an alarm and finally a slow-down is given, depending on the magnitude of the flow deviation.

-

Solenoid valve and lube check sensor

The solenoid valve receives an activation signal. The signal activates a hydraulic valve that opens for the pressure. This moves the pistons up and supplies oil to each lube point.

There is a master and a backup solenoid valve, for redundancy. When the pistons move up, there is a check sensor to confirm movement. If the pistons have not moved after 5 strokes the system will automatically change to backup and remain until the system is reset. When changing to backup a warning will generate.

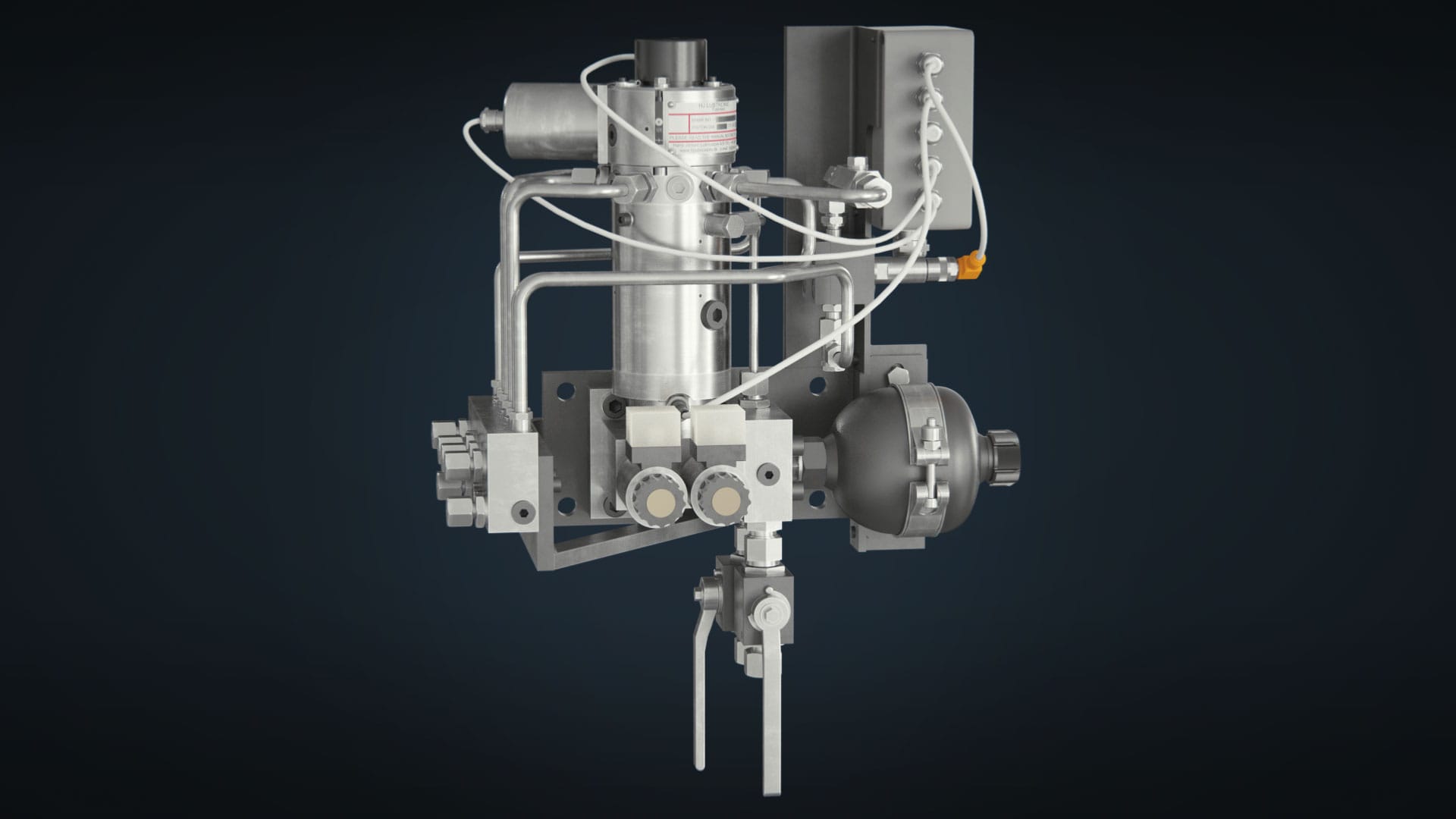

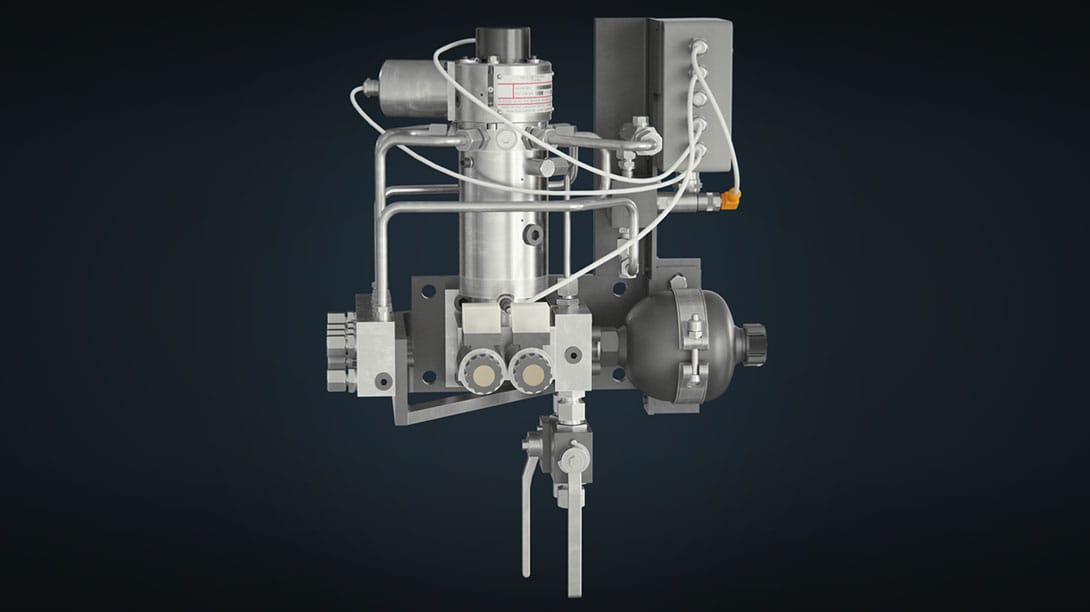

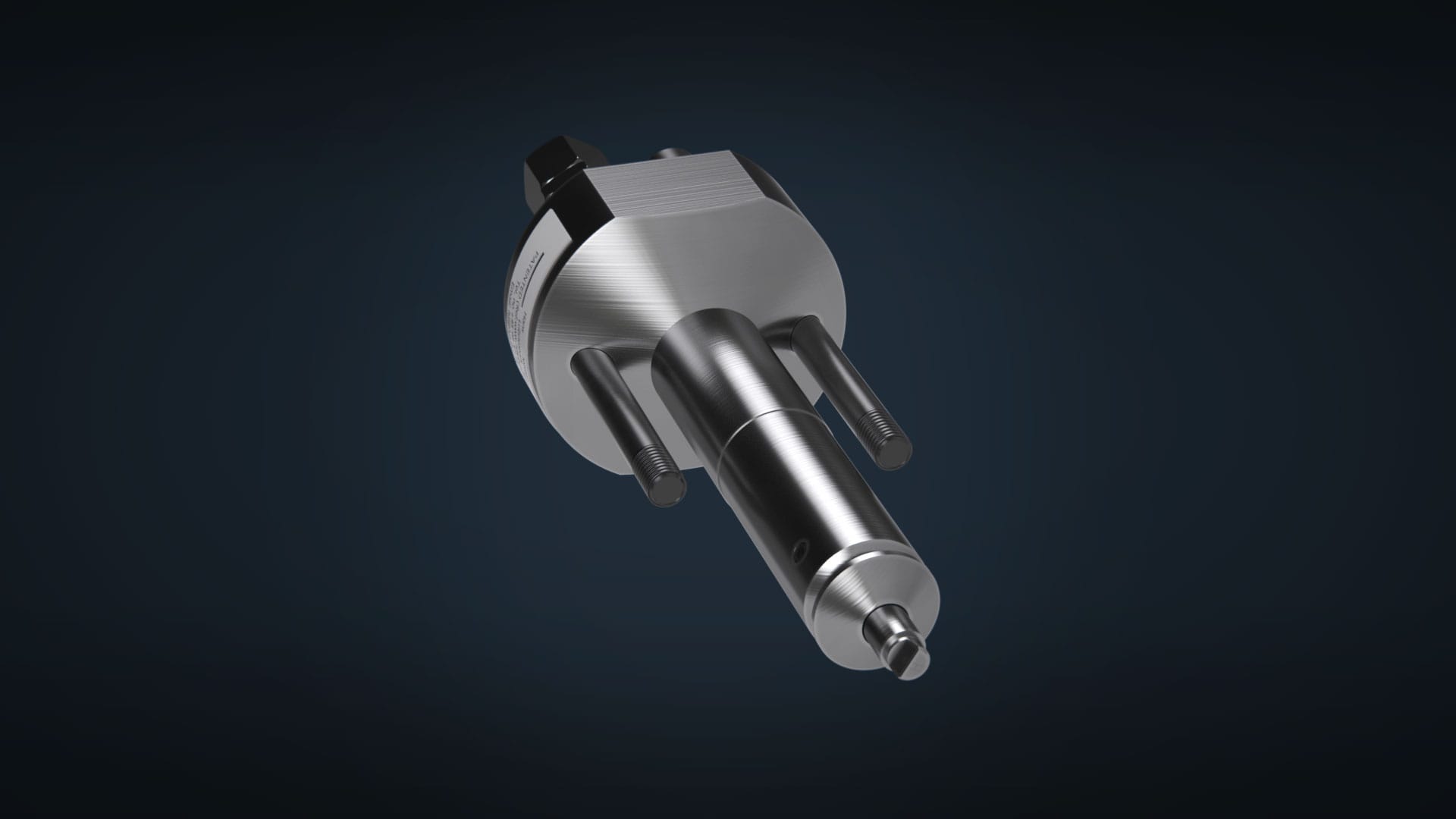

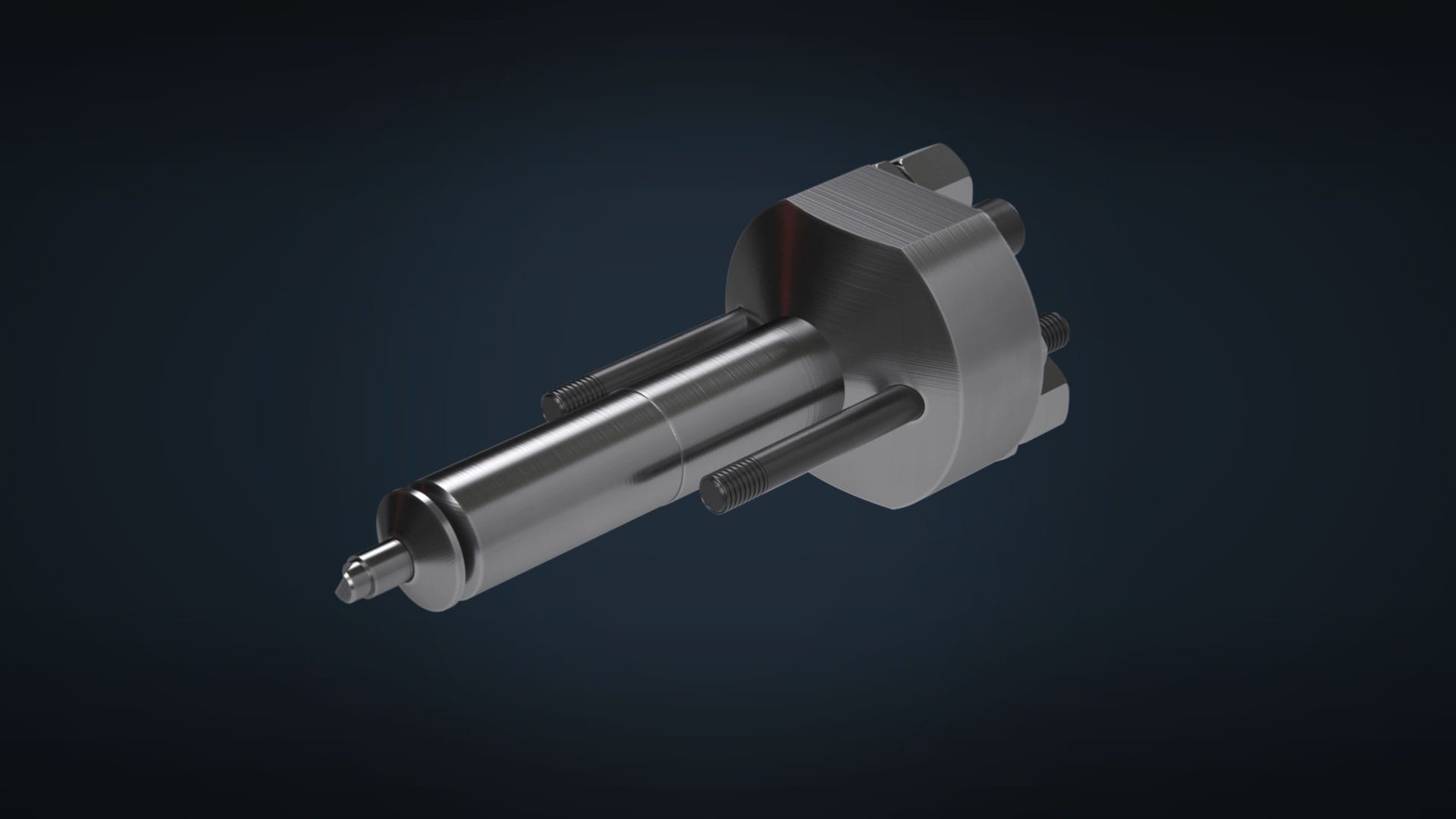

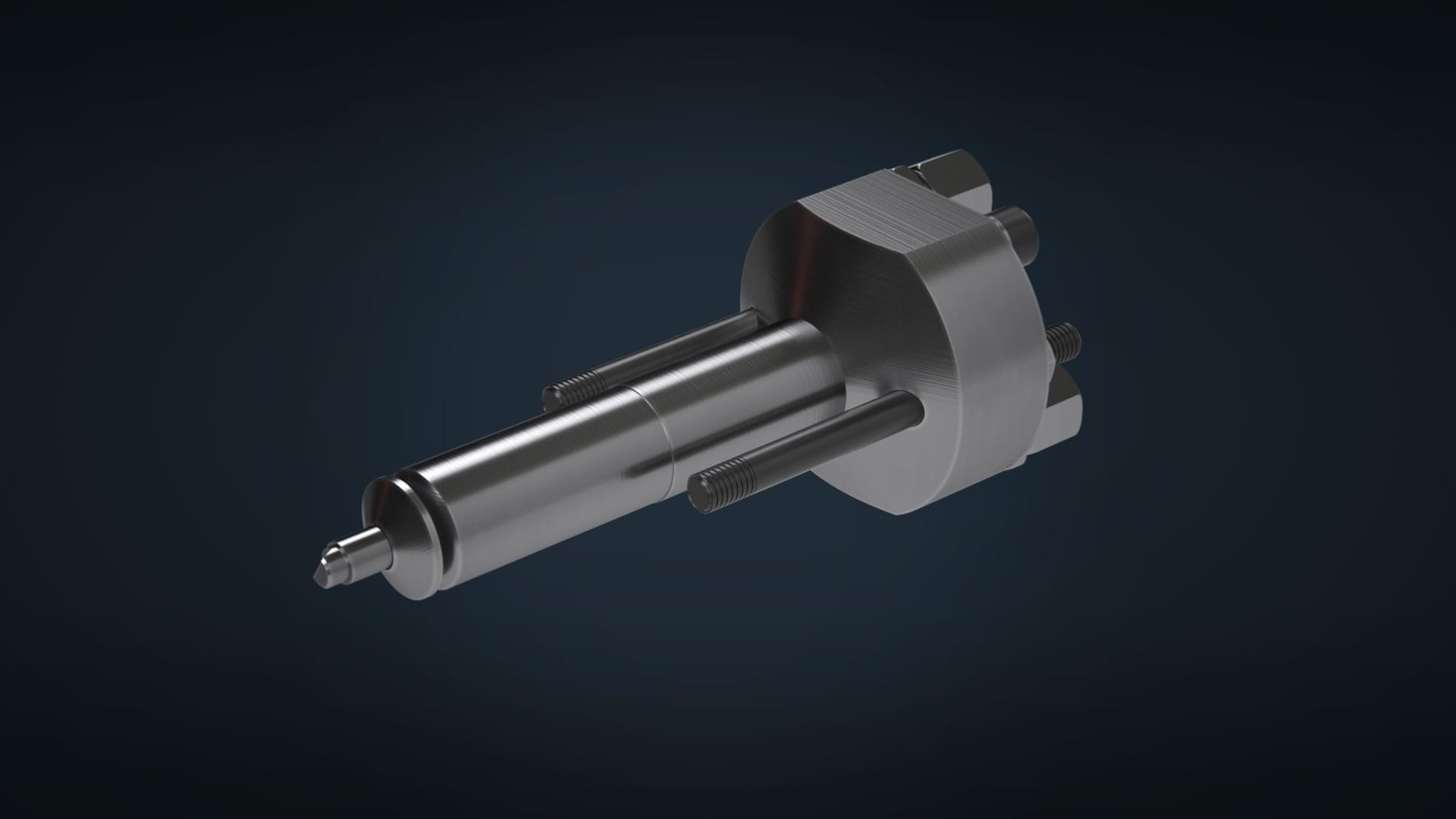

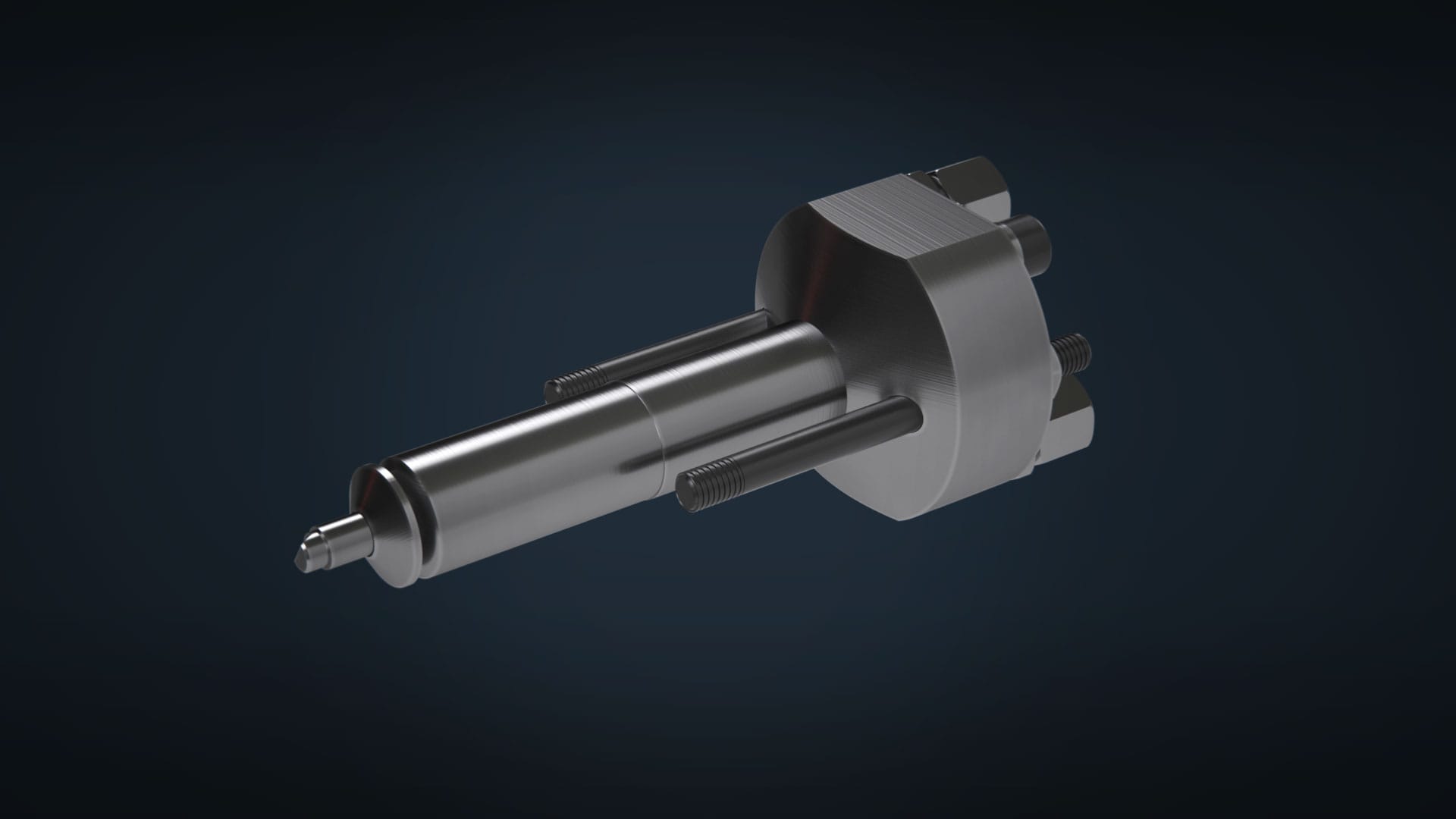

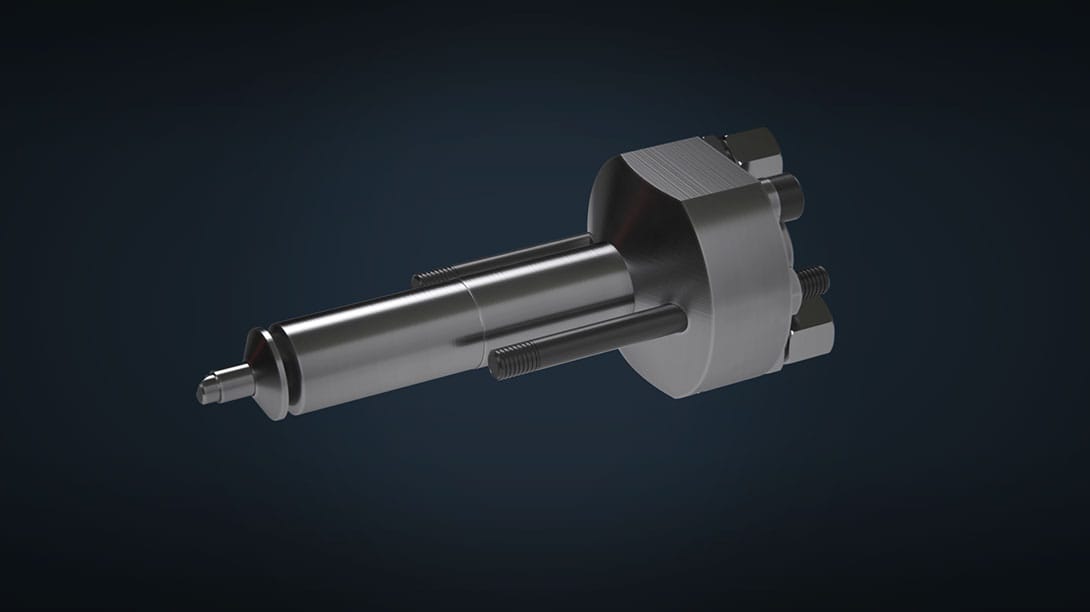

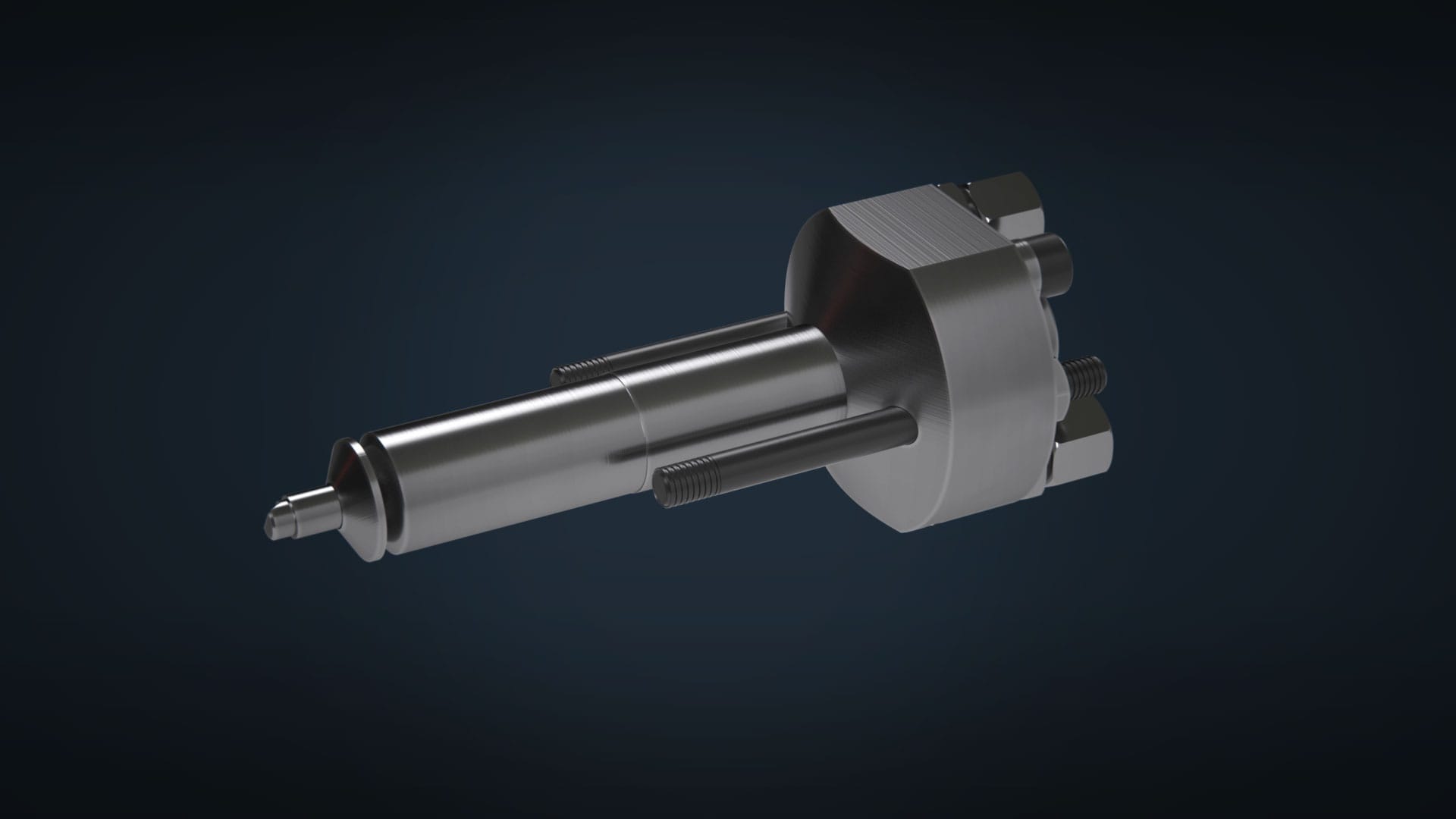

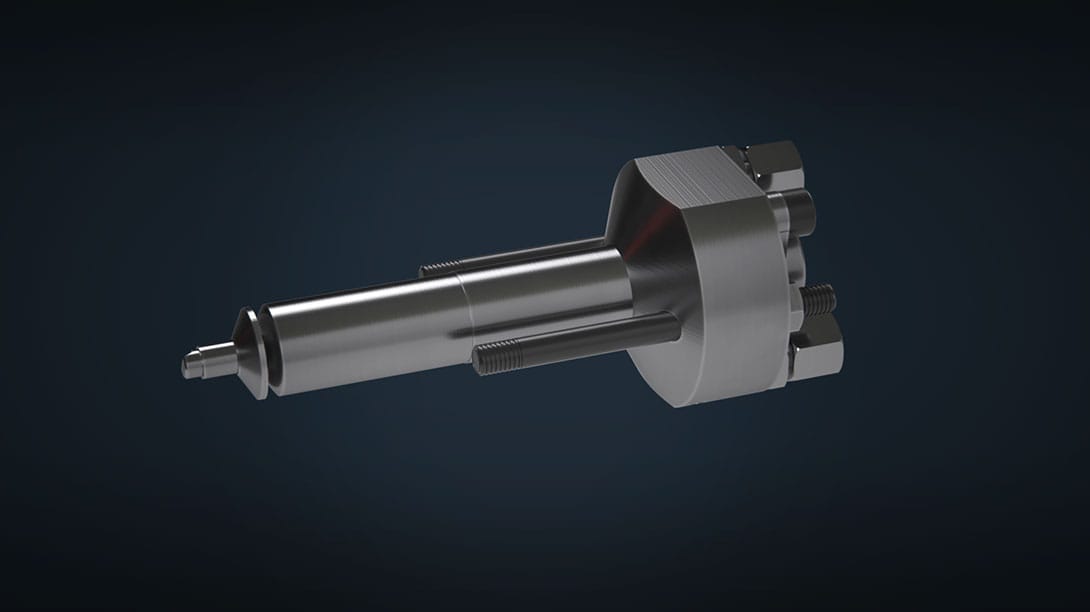

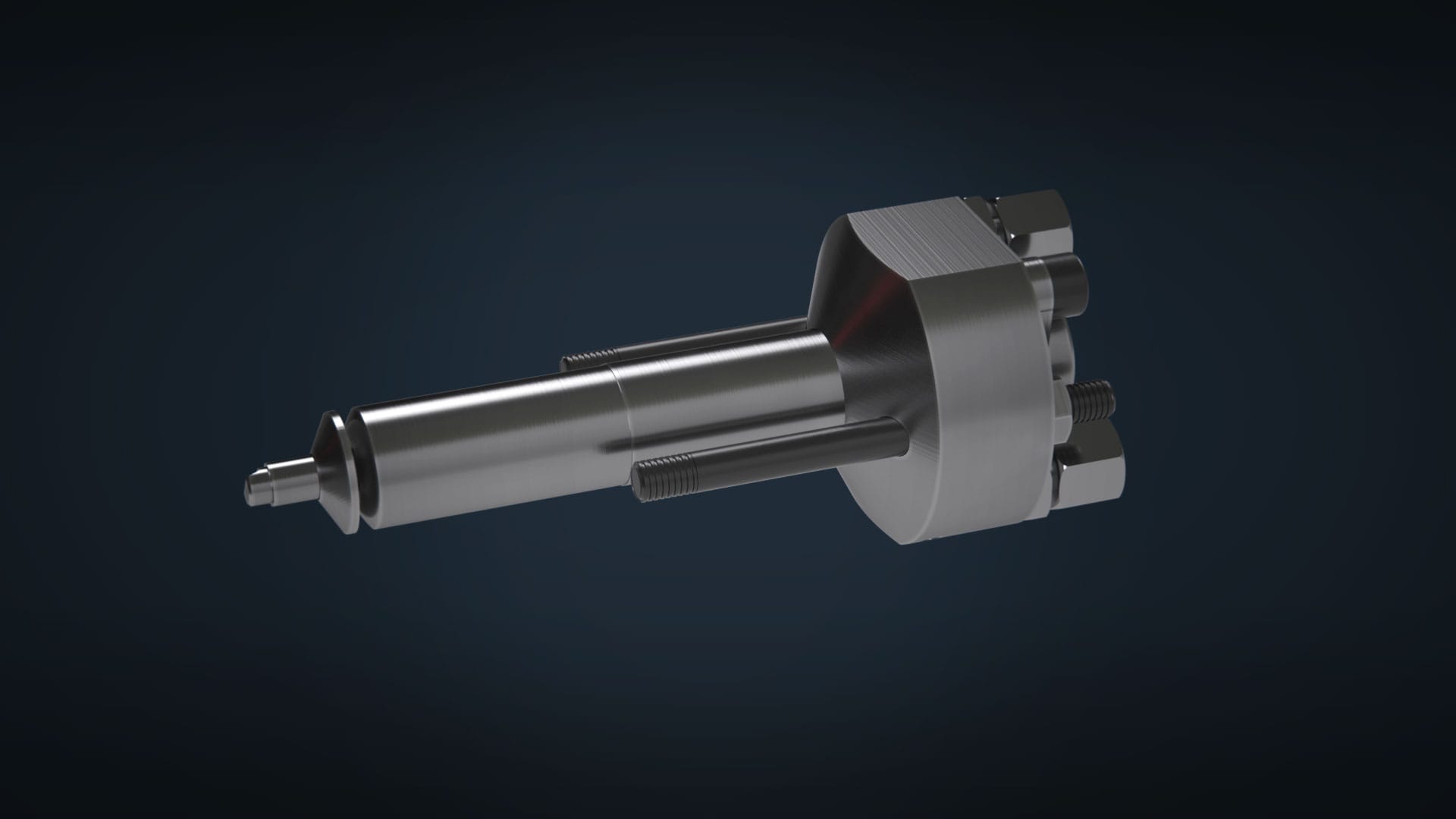

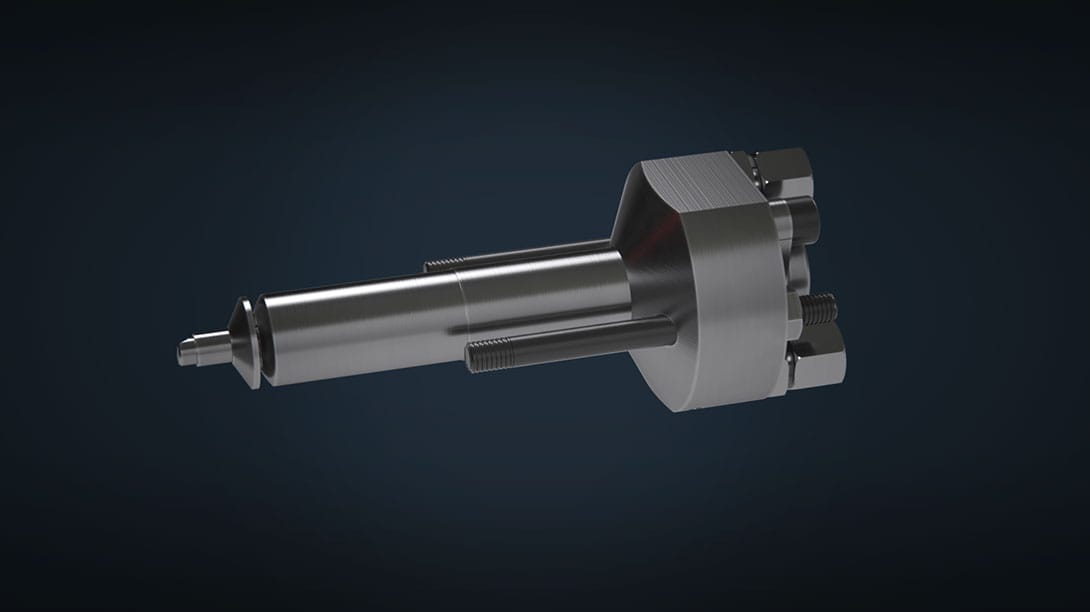

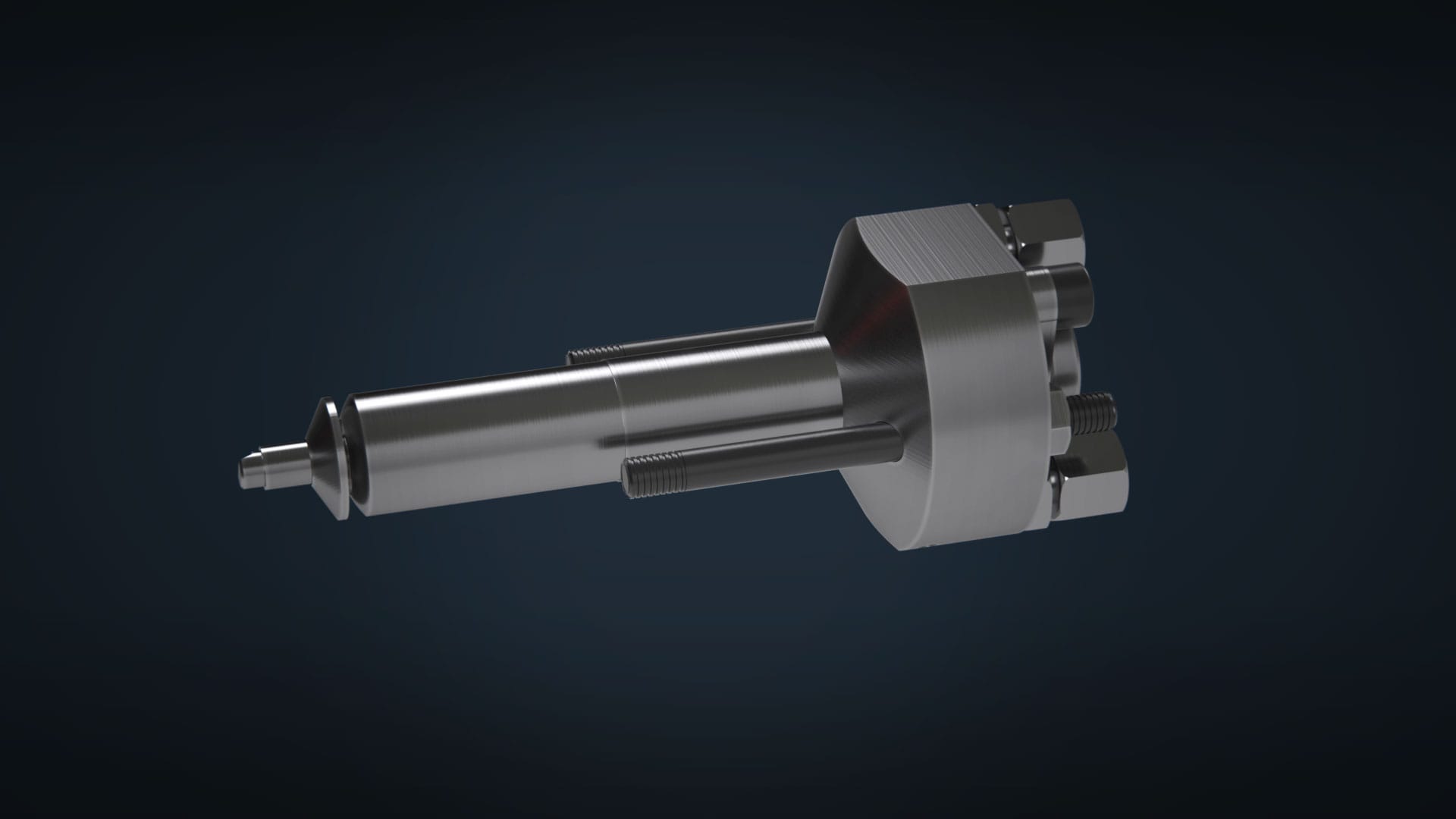

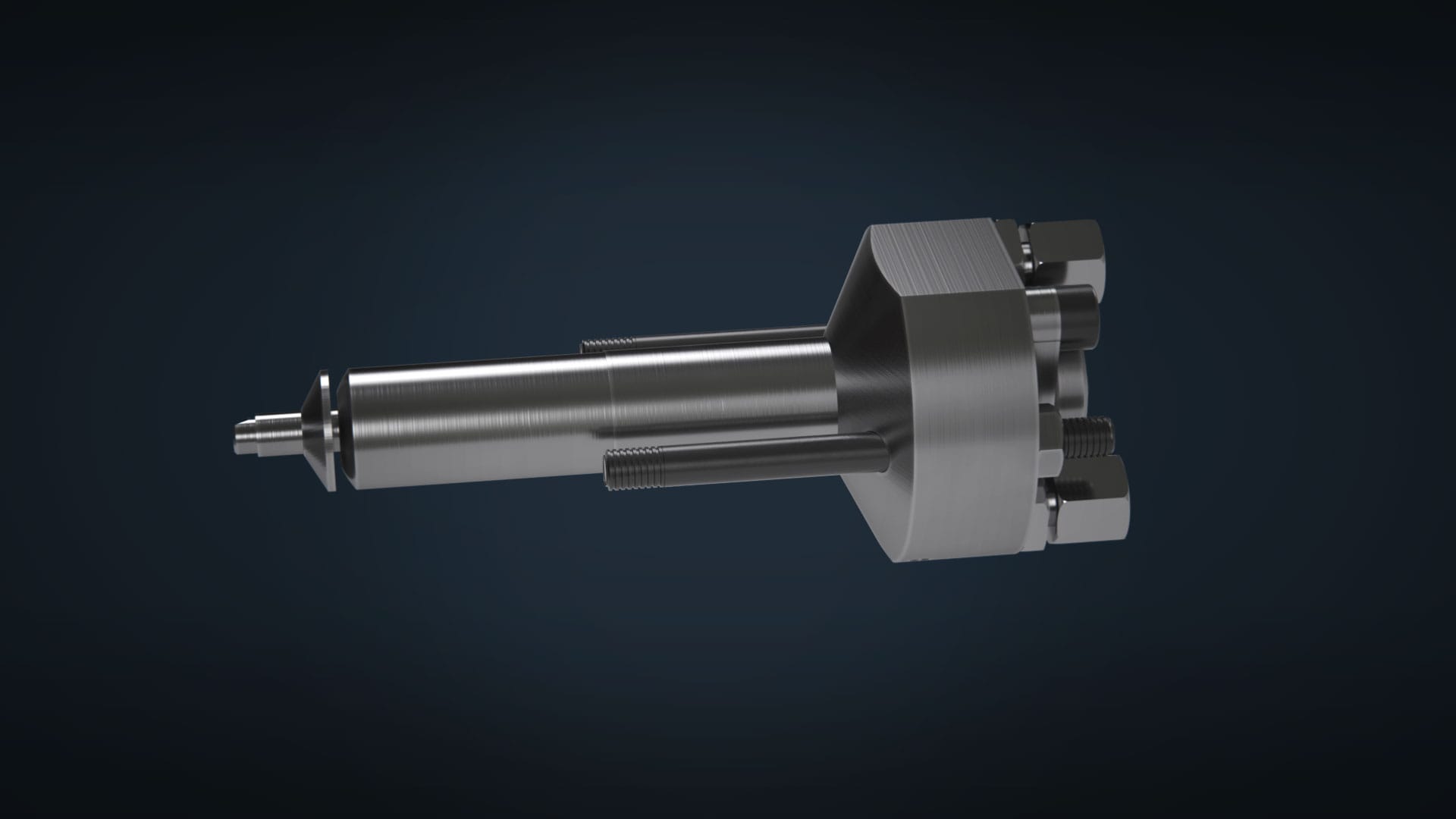

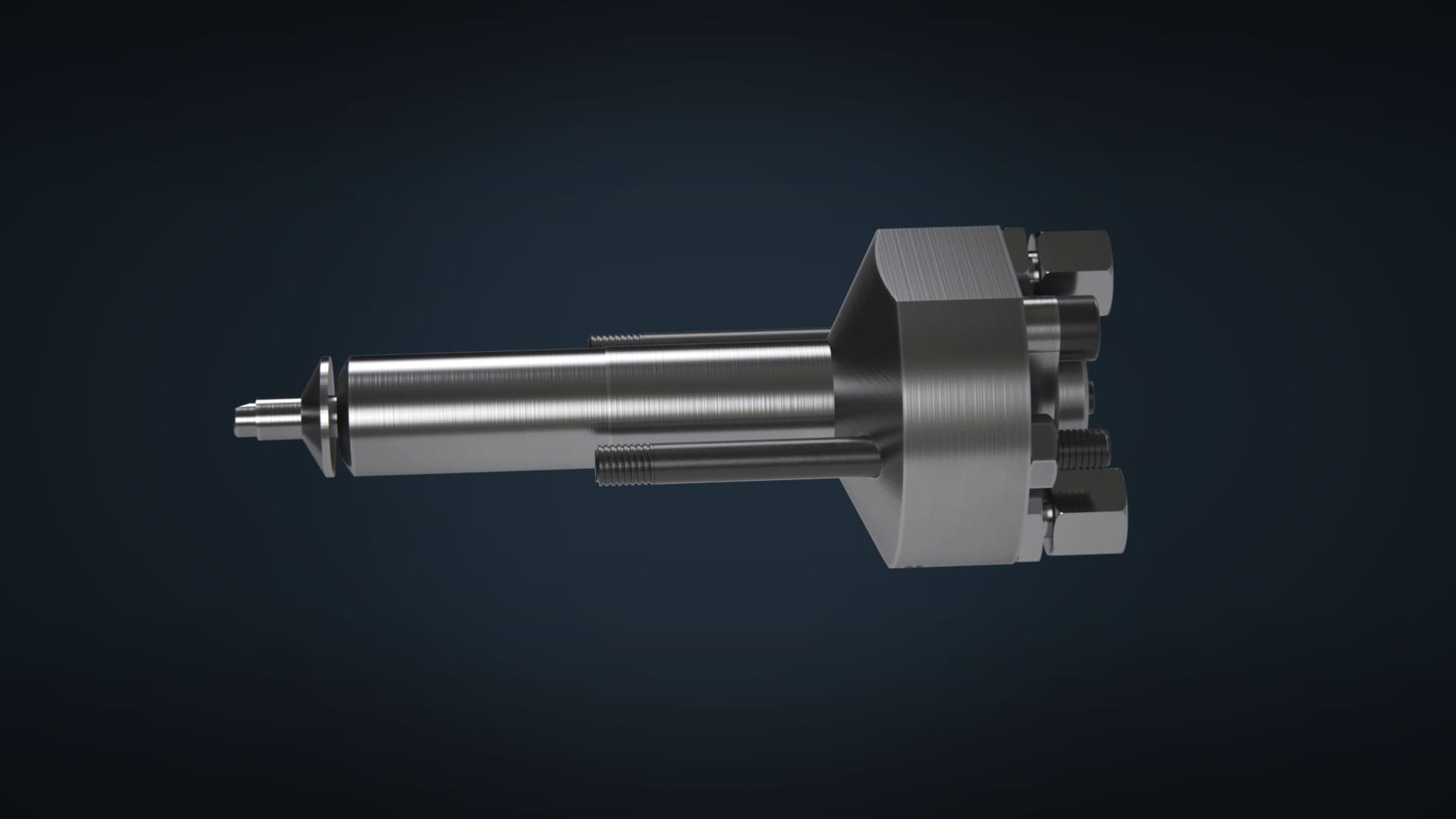

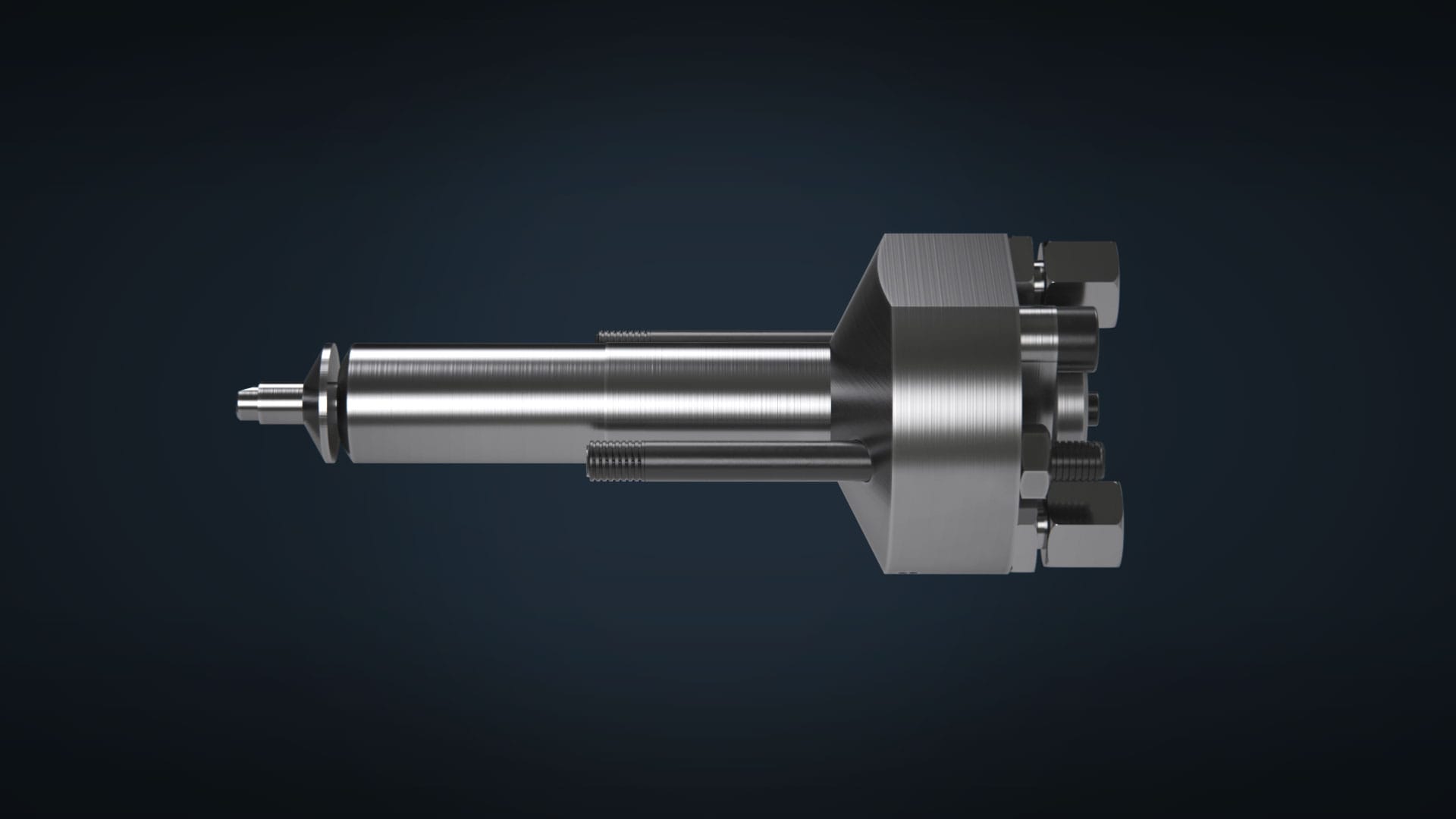

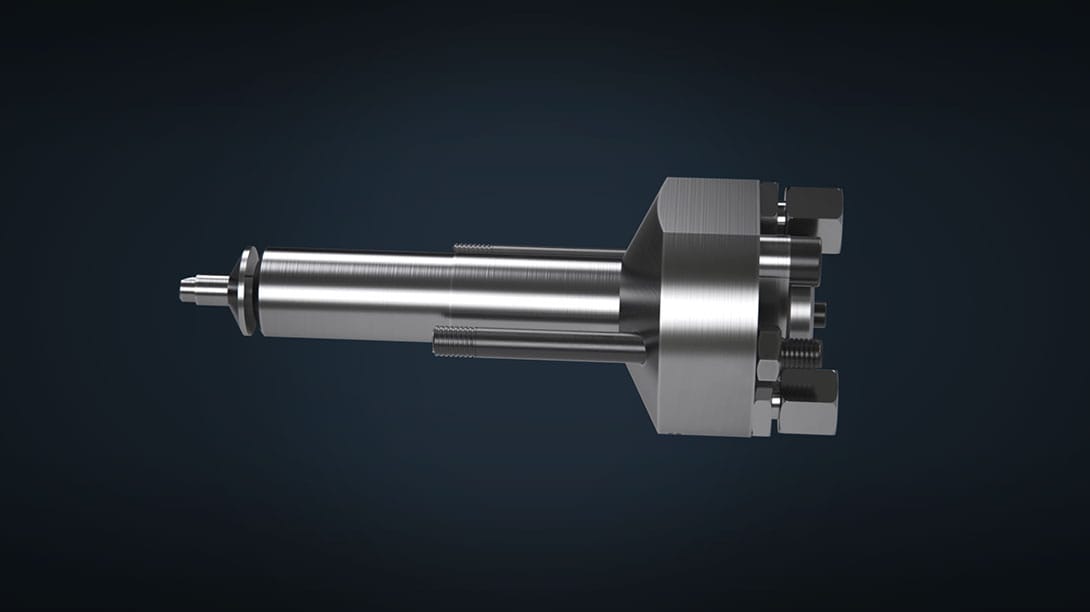

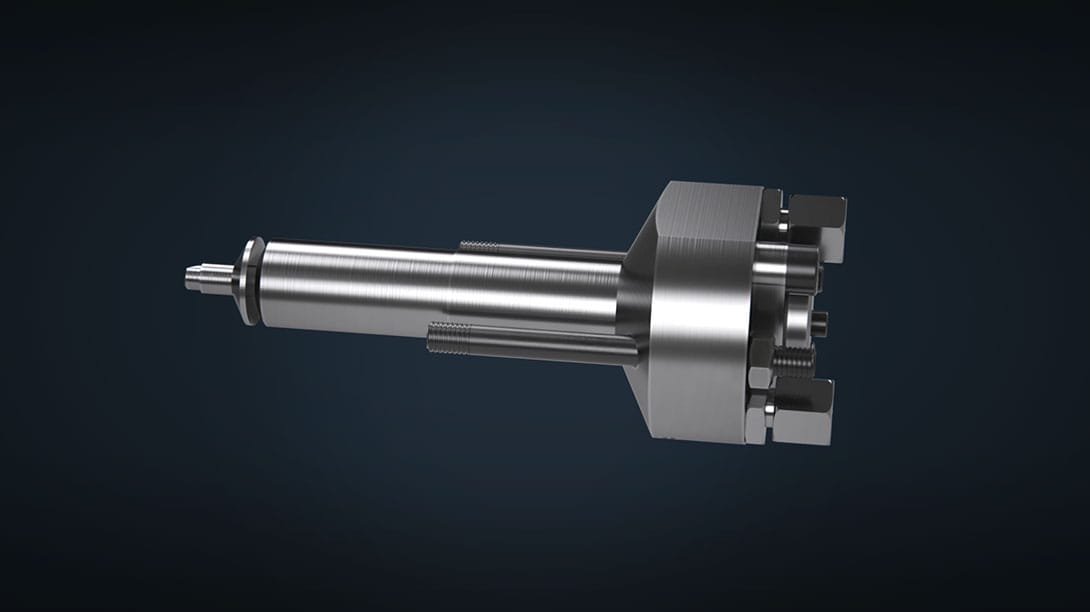

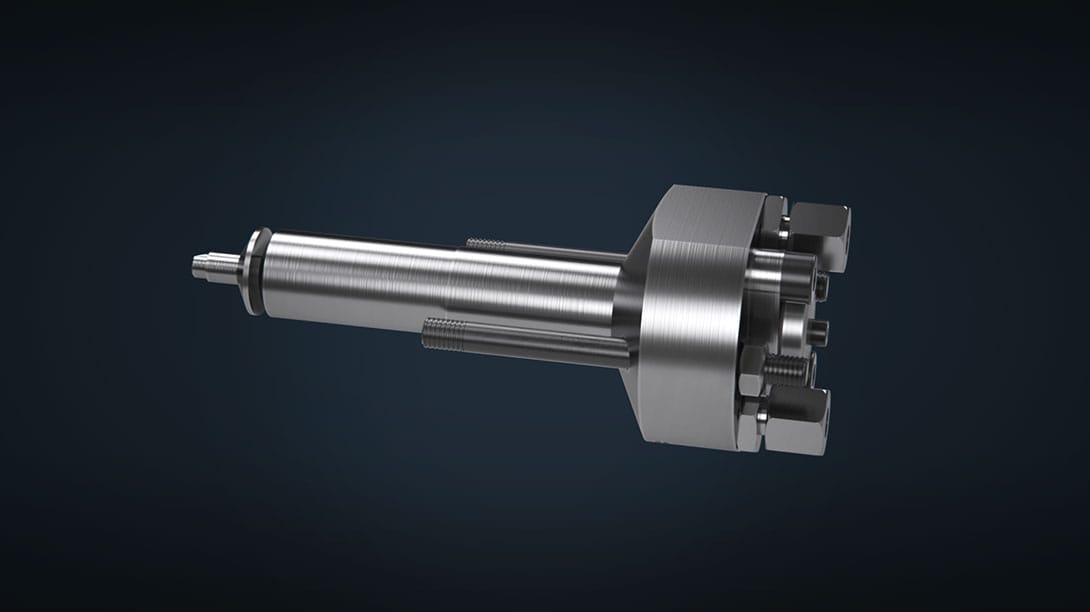

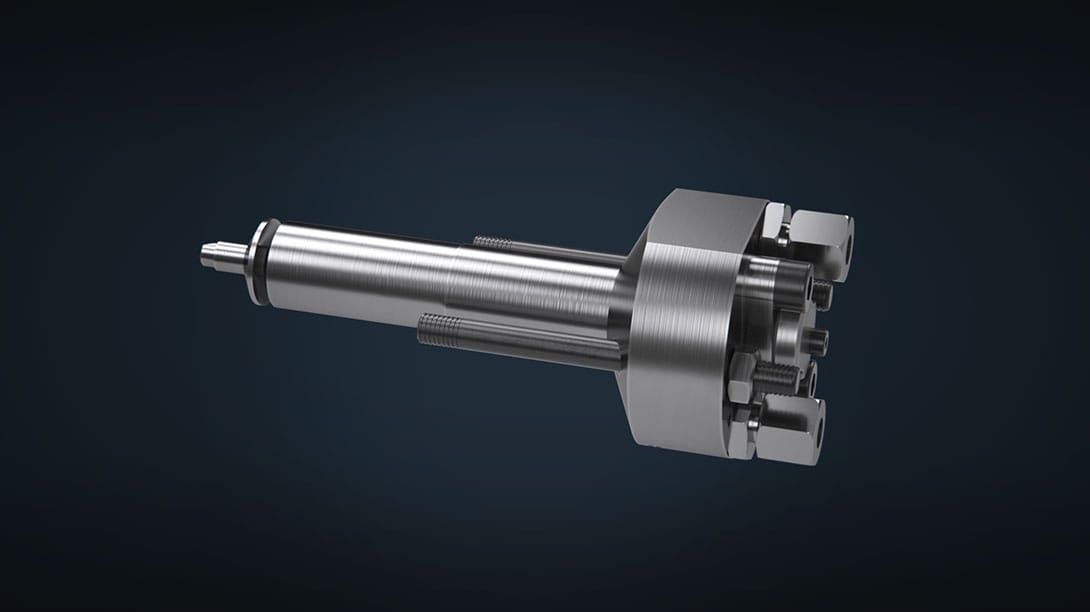

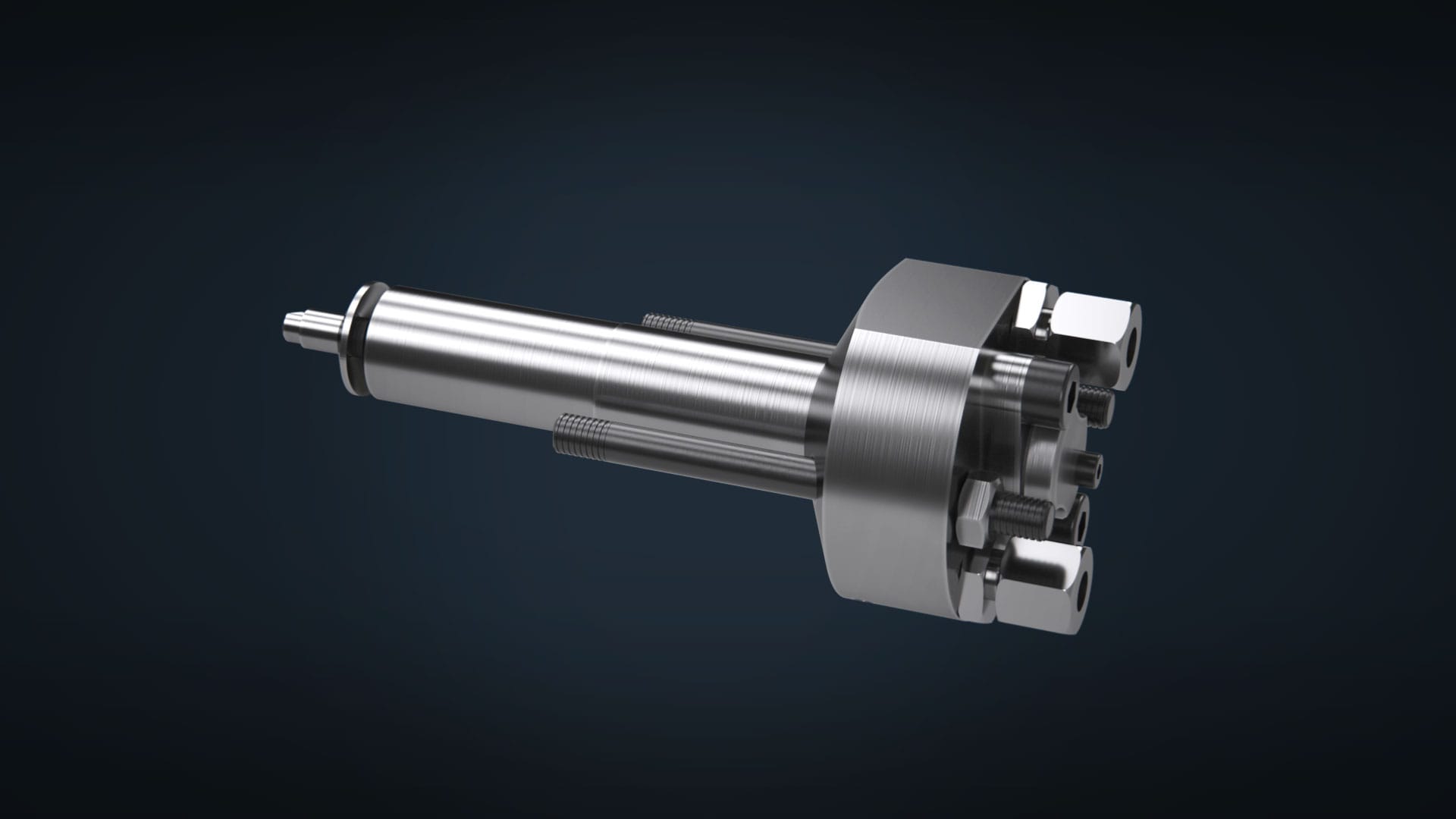

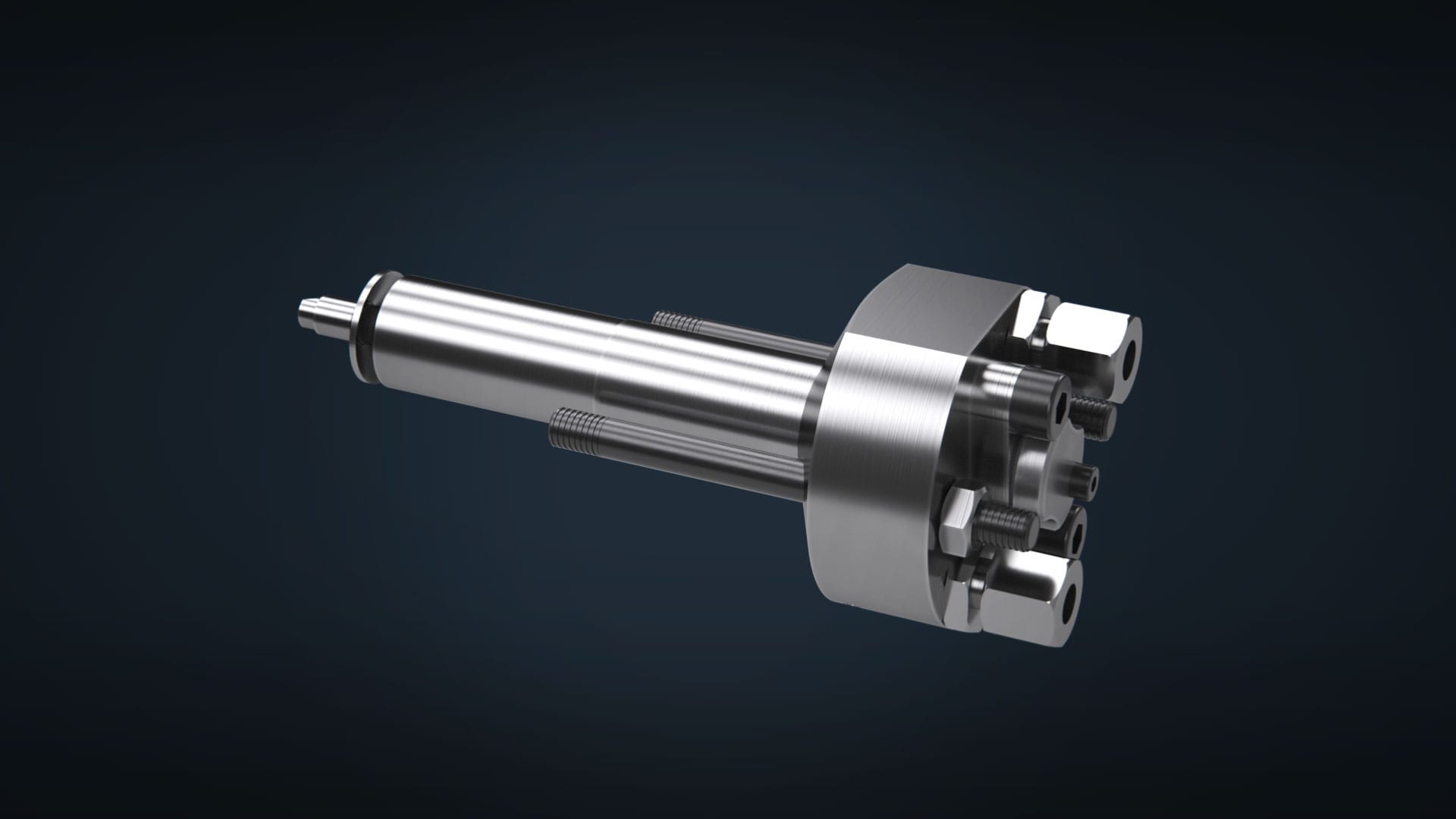

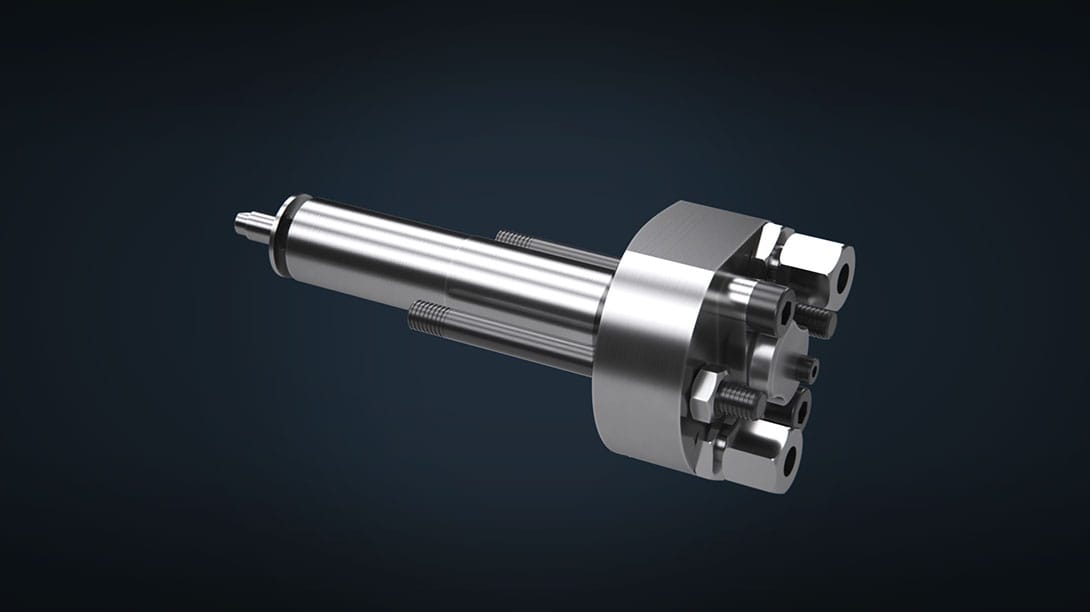

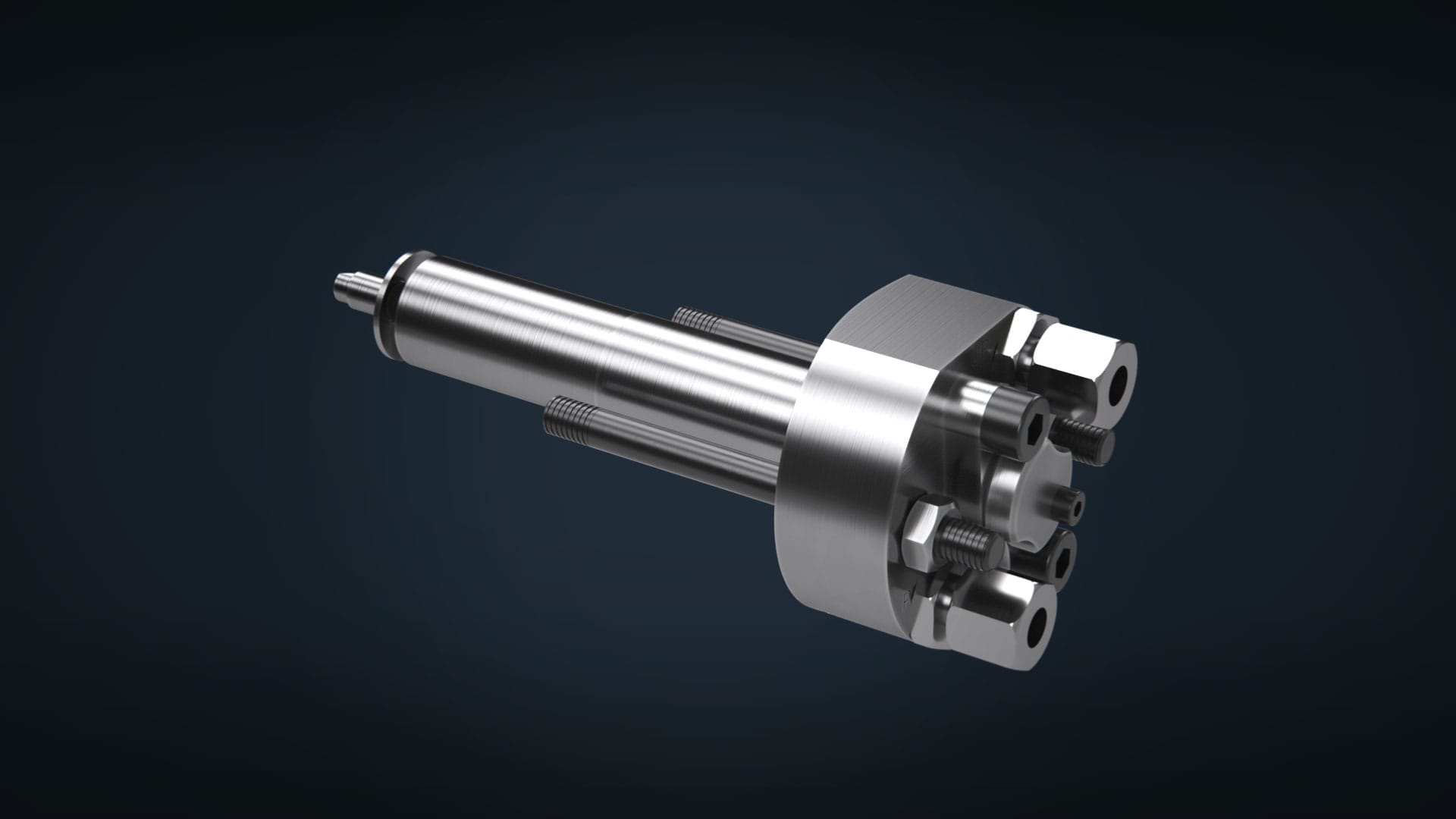

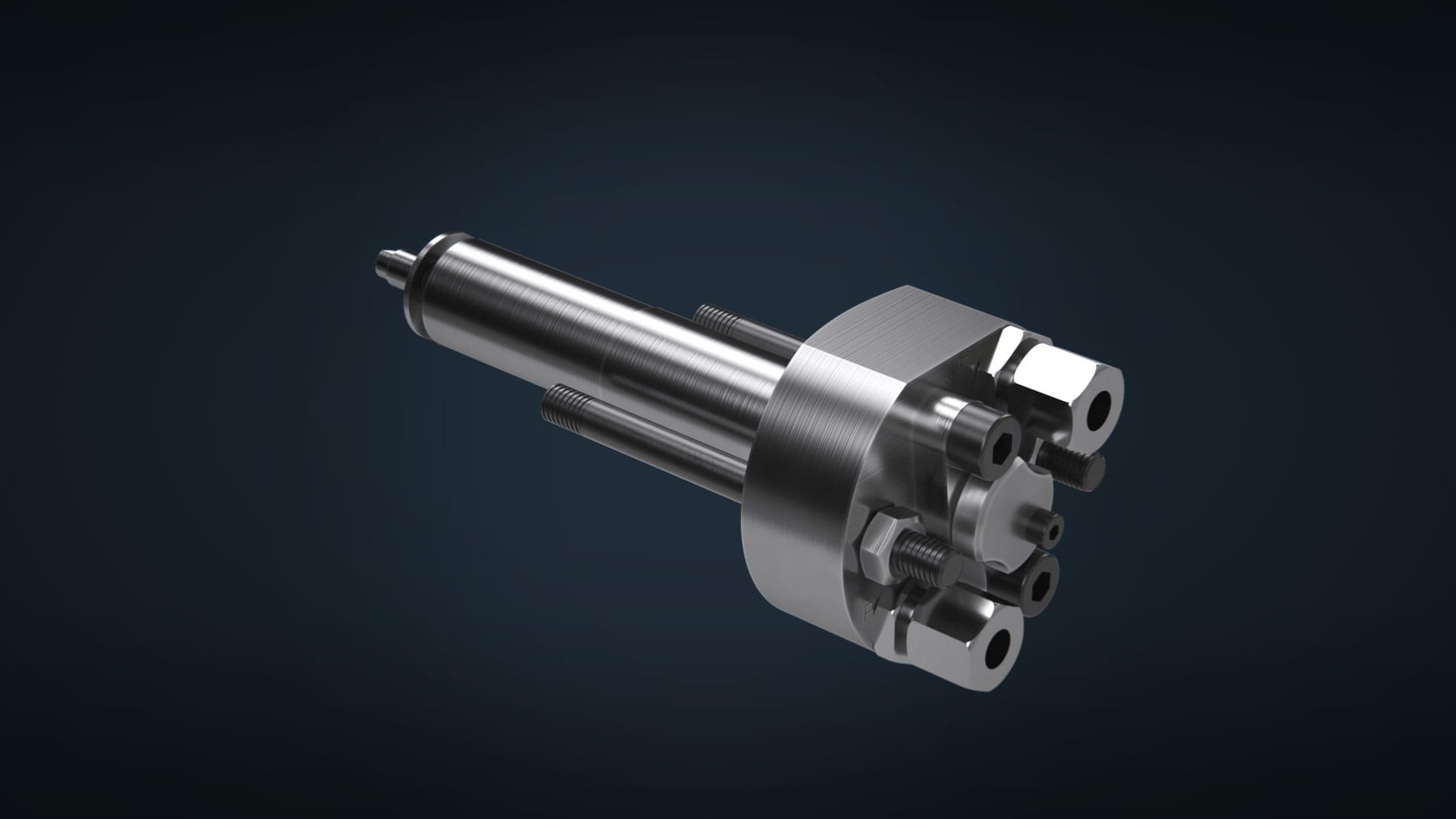

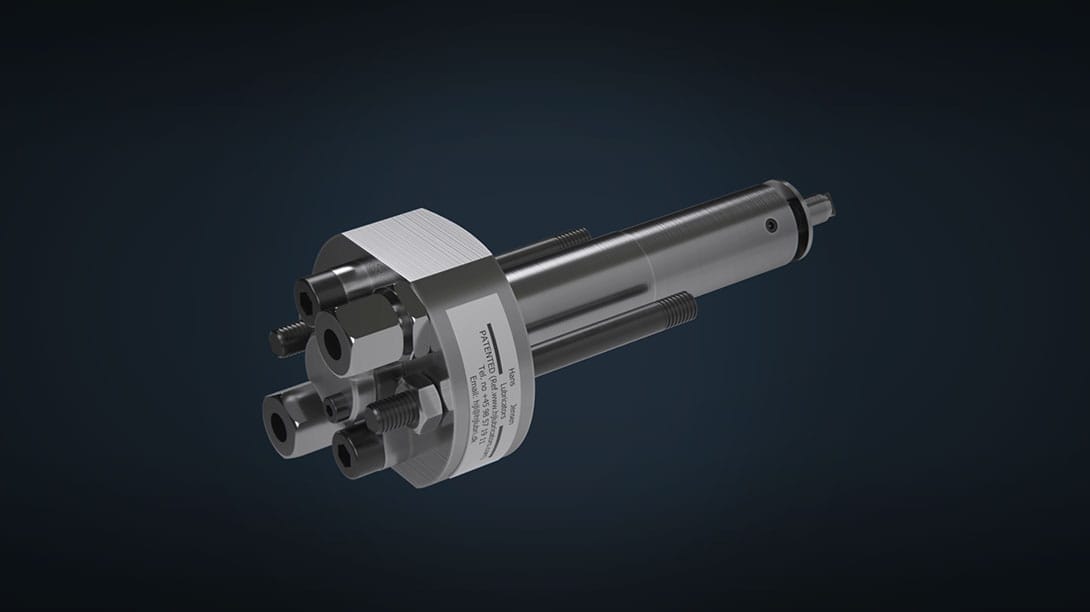

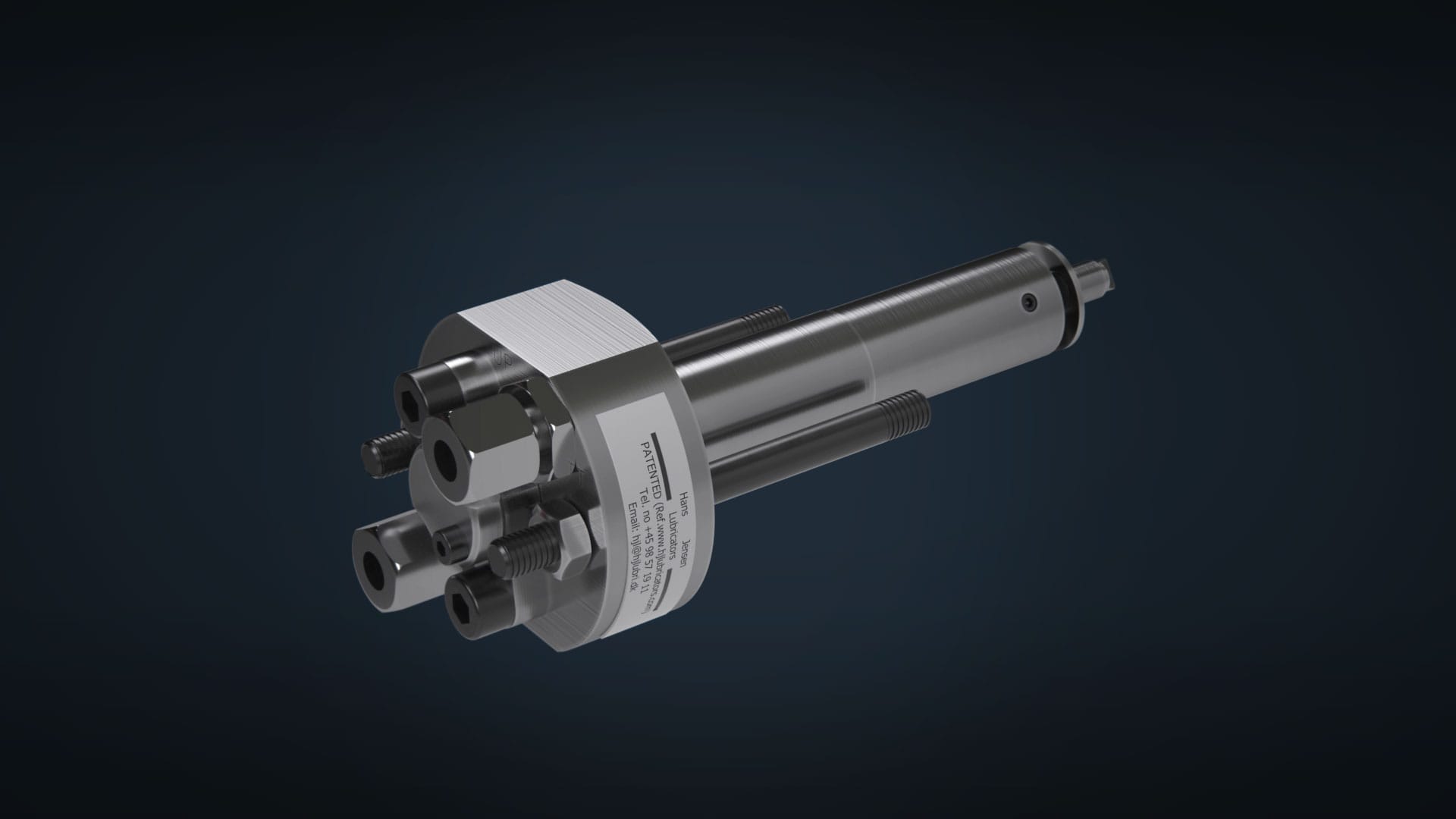

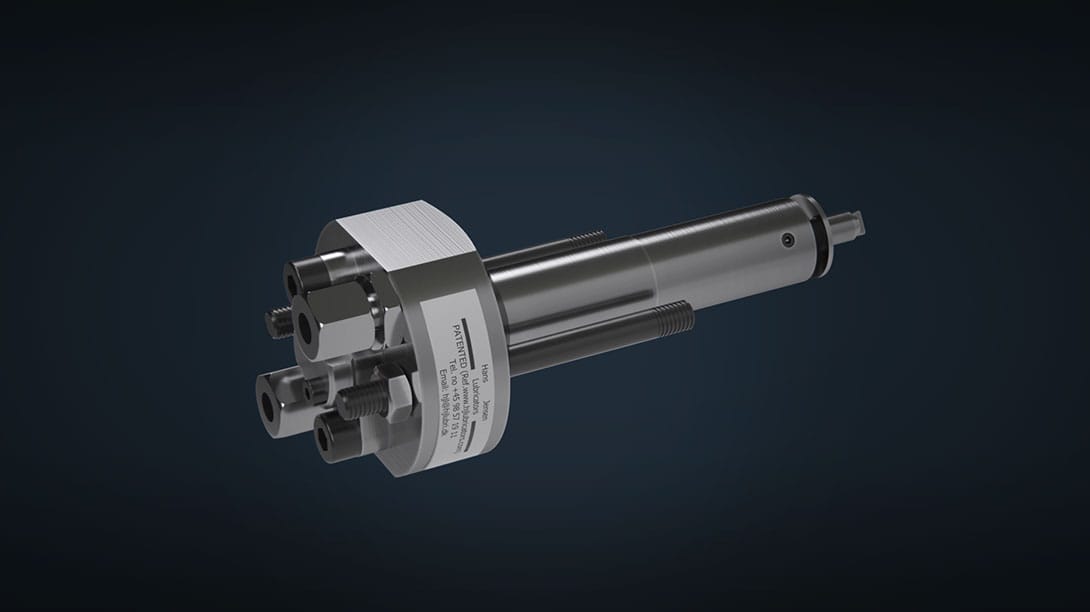

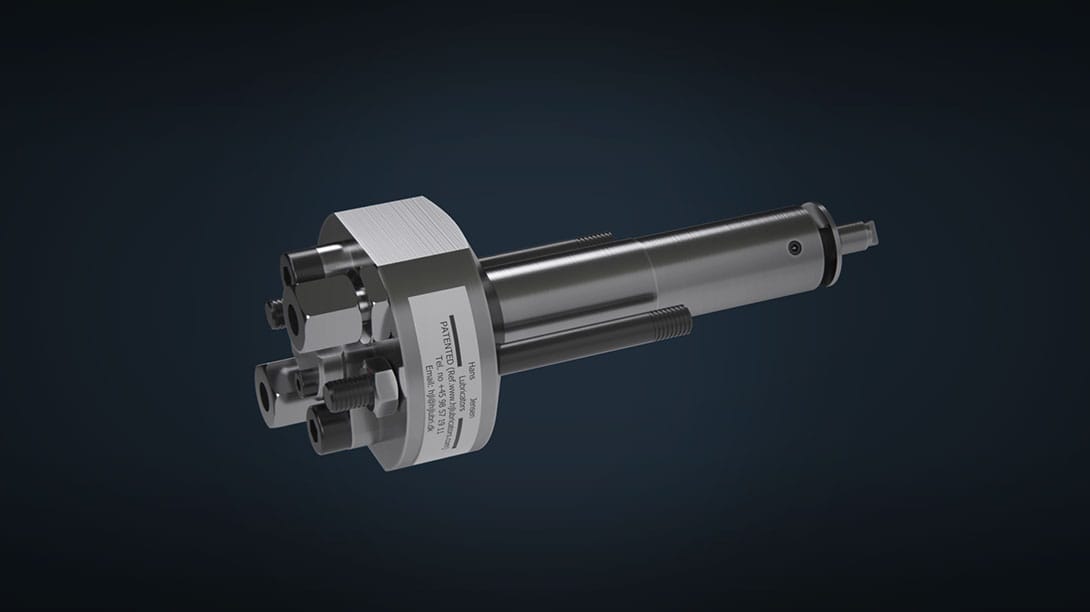

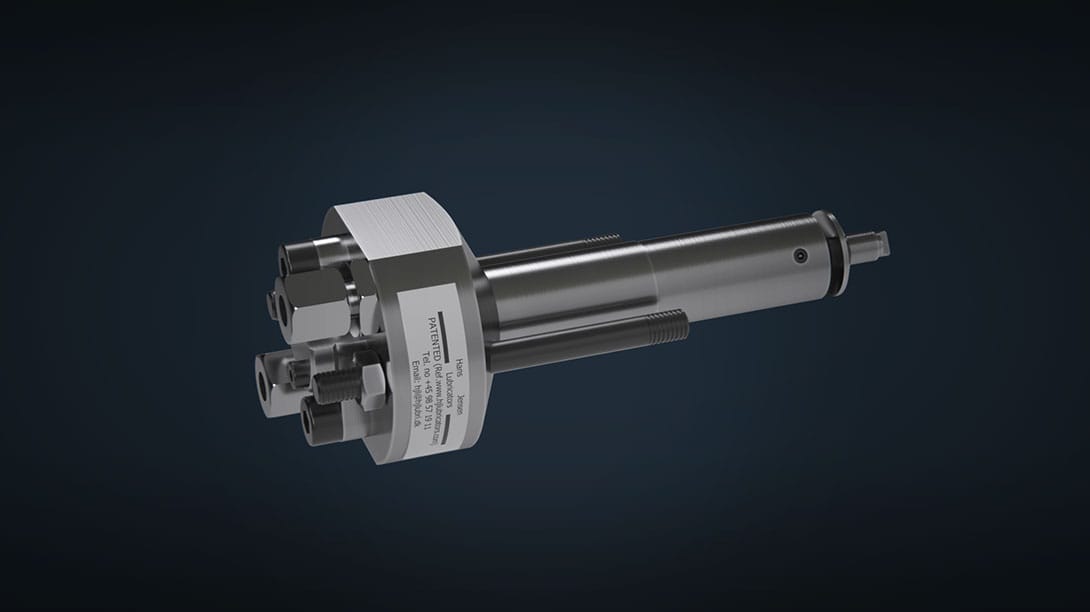

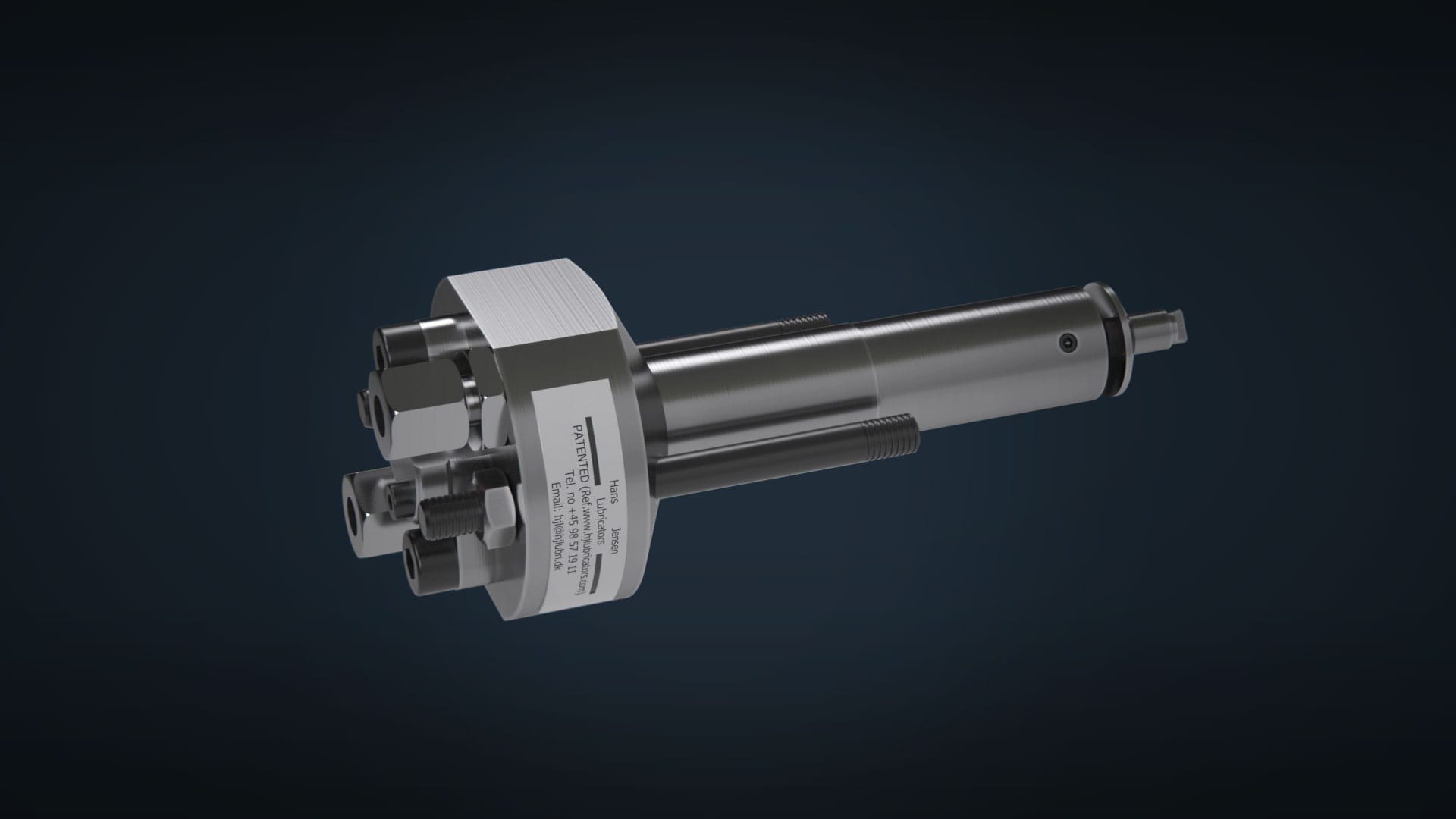

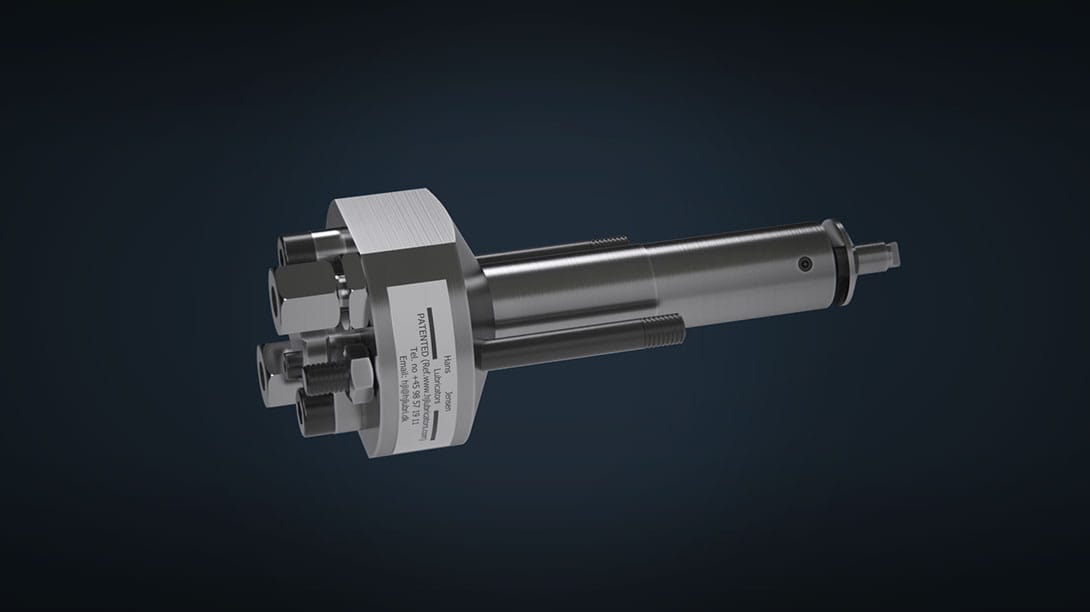

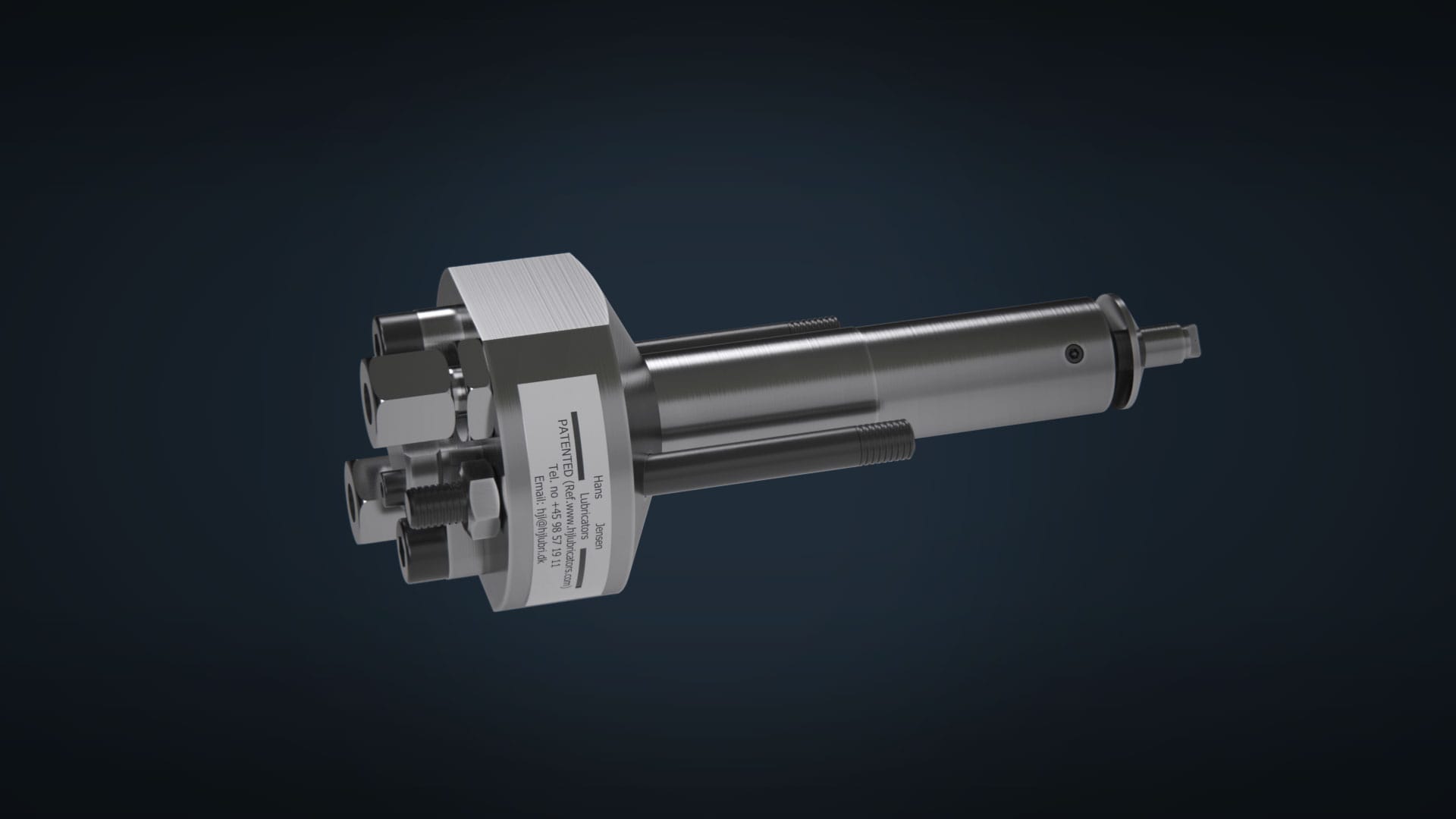

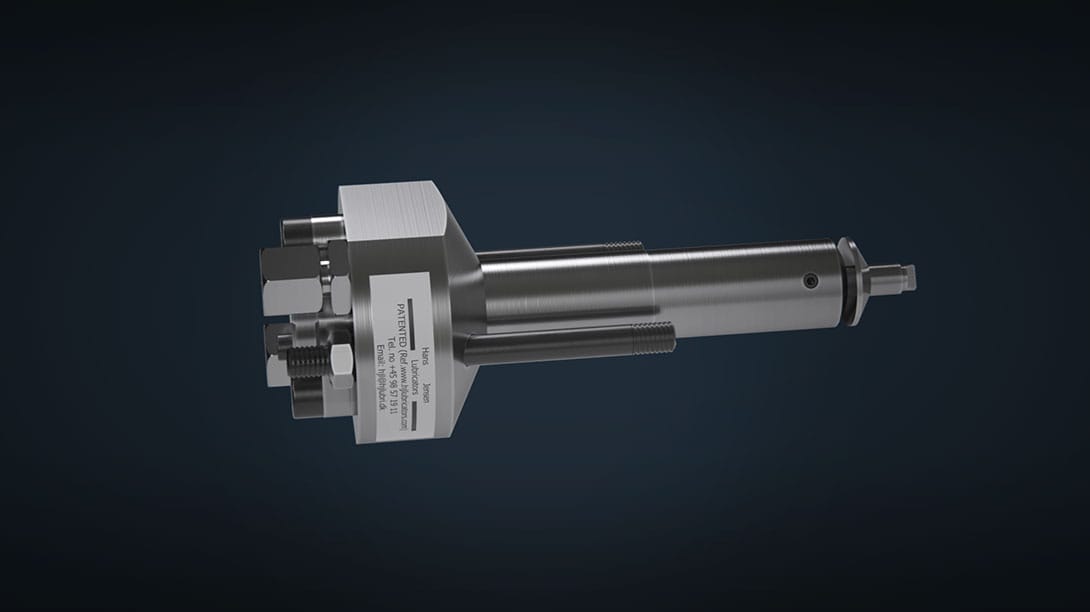

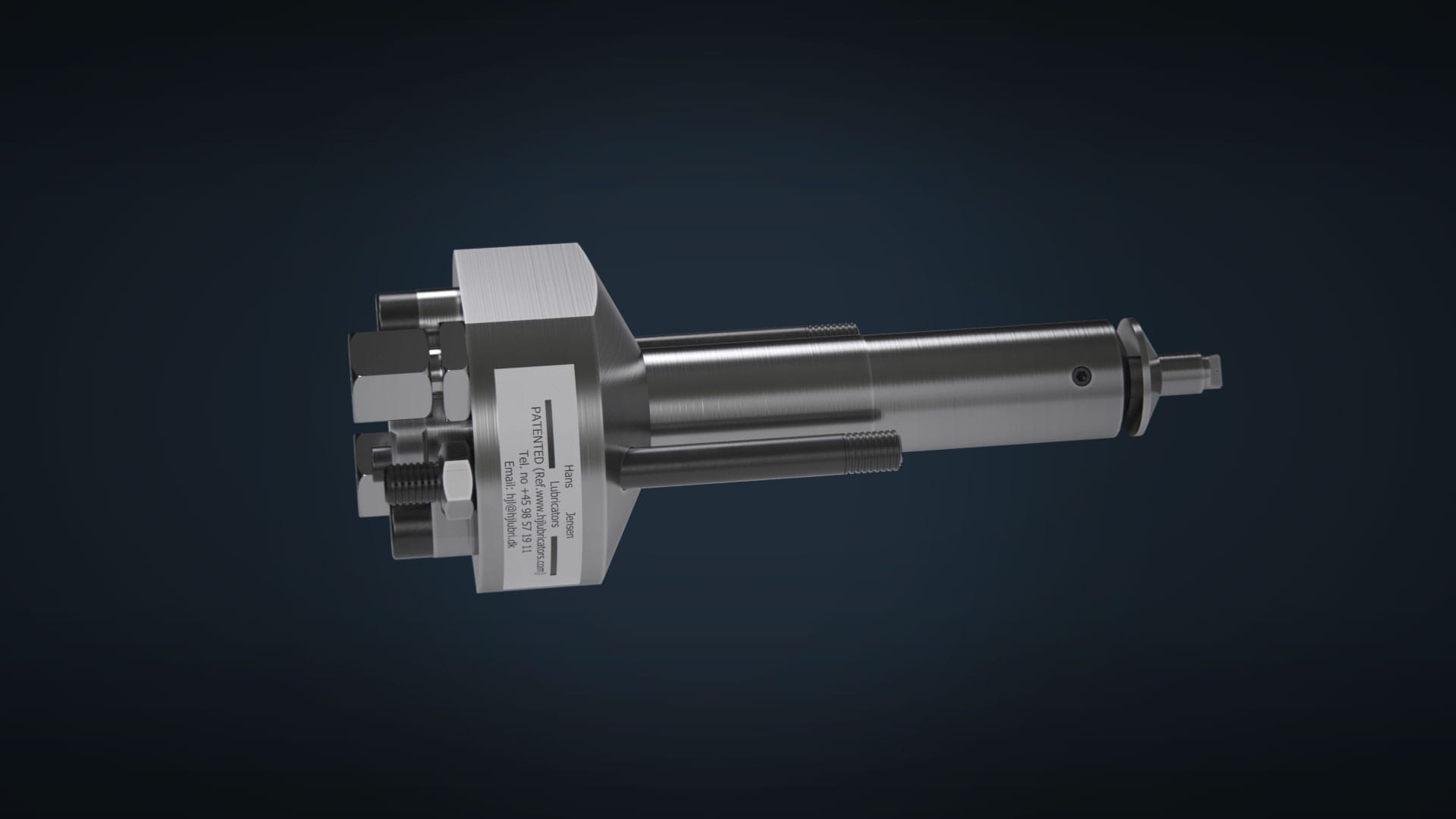

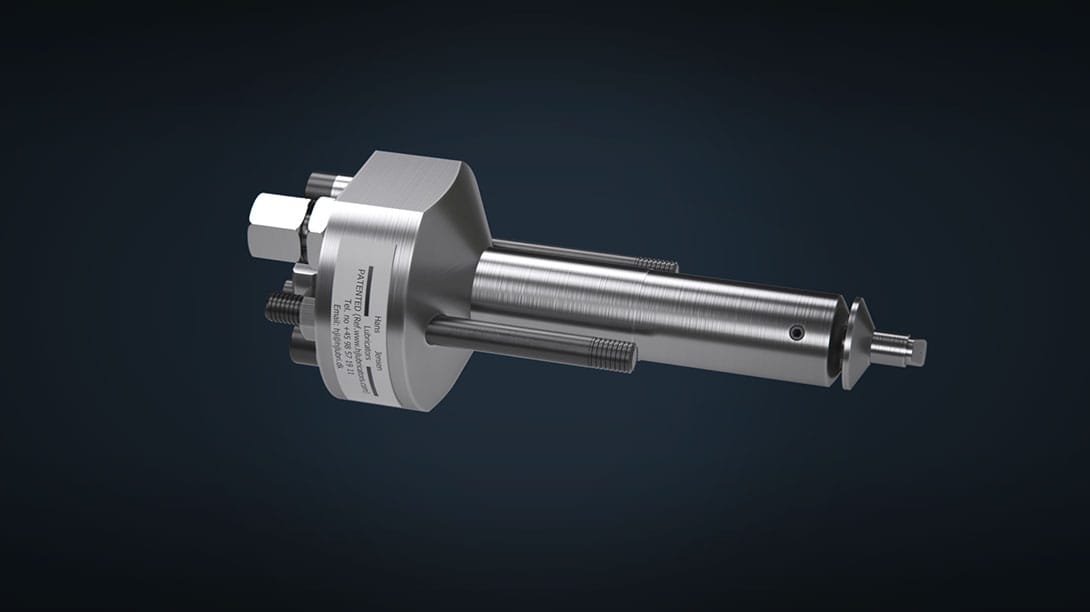

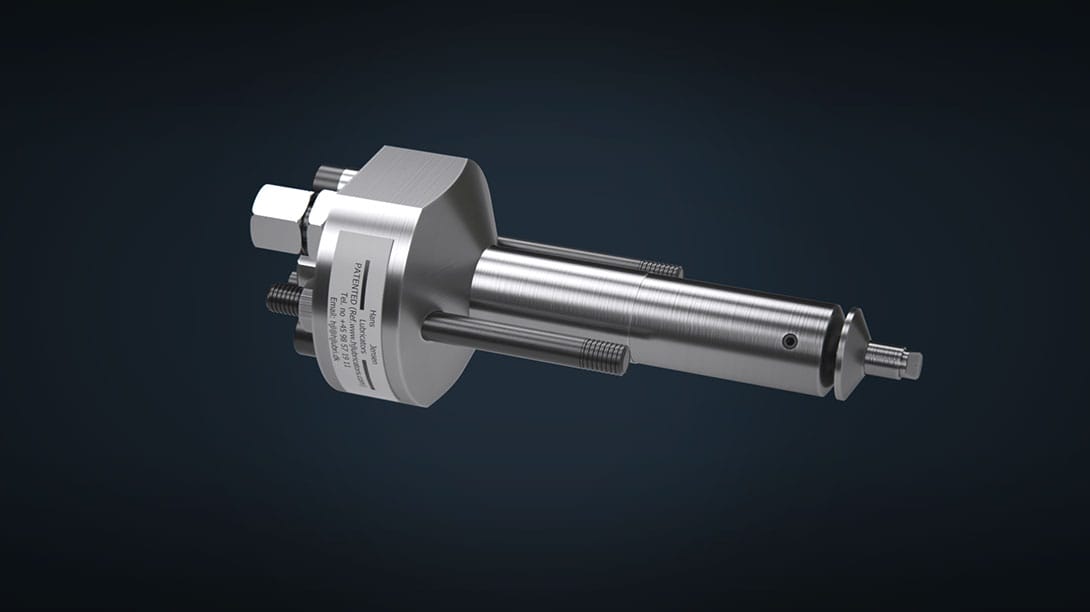

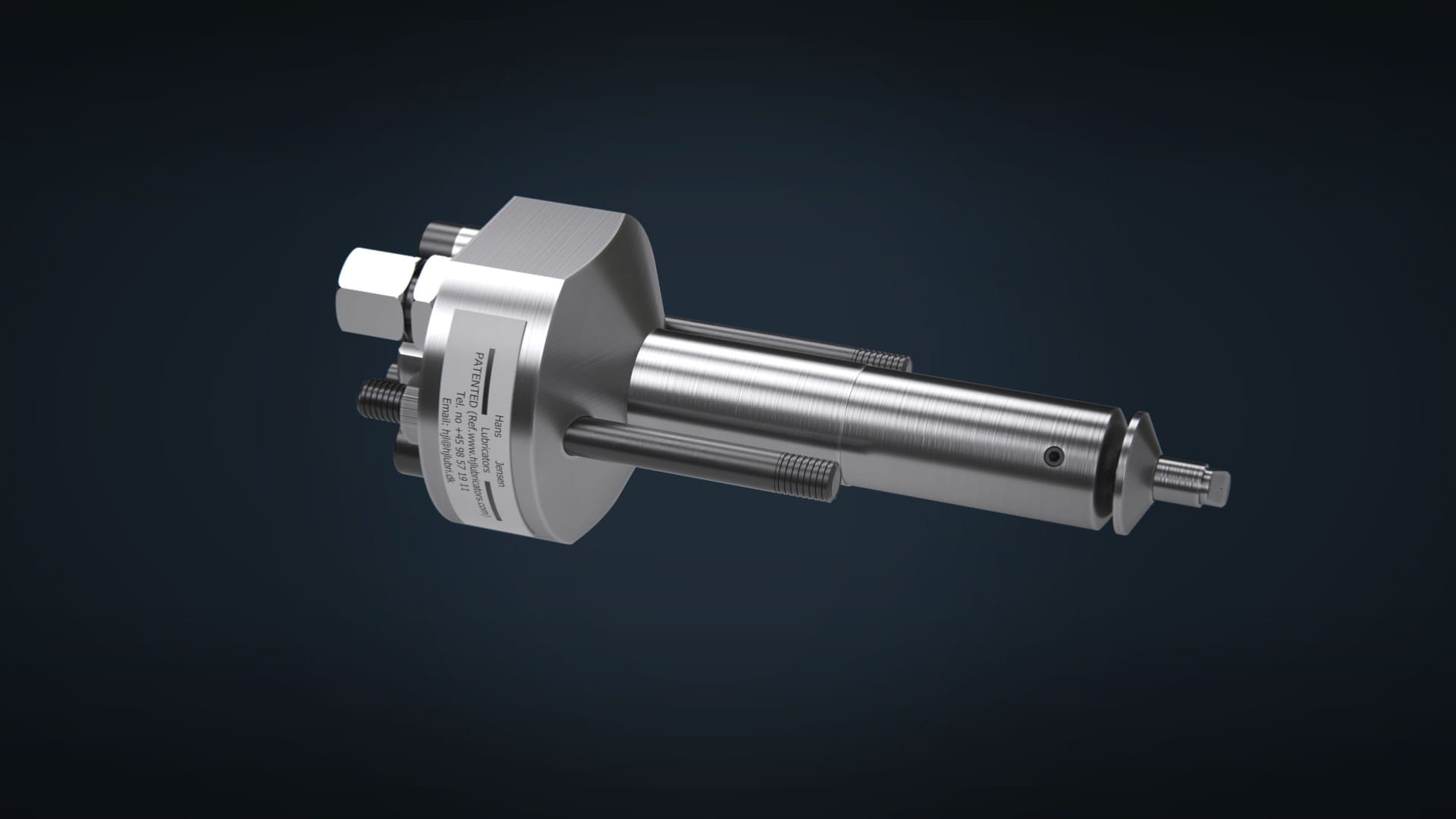

HJ SIP valves

The HJ SIP ”Swirl Injection Principle” is a cylinder lube oil injection valve that sprays oil in tiny droplets utilizing the centrifugal power of the scavenging air swirl, ensuring optimum distribution of injected oil and thus an efficient use of the lube oil. HJ SIP works on all engine types and designs

- Fresh oil injection in every piston stroke

- Atomizing cylinder oil into the combustion chamber

- Efficient dispersion on the liner wall and piston rings

- Automatic load or Sulphur dependent feed rate regulation

- Automatic Cleaning Sequence algorithm

- Delta-Timing algorithm ensures lubrication into the ring pack and liner

- Possibility for online monitoring and preventive alarms

-

Nozzle

The cylinder lube oil is sprayed into the cylinder through the nozzle opening. By spraying the lube oil in tiny droplets, into the scavenging air swirl a large surface area of the liner is covered to ensure optimal distribution of the cylinder oil. This in turn, ensures proper utilisation of the oil.

The nozzle opening is turned at an angle and injects the oil upwards onto the upper part of the cylinder liner where it is most needed, overlapping the next HJ SIP injection point.

-

Pressure plug

Adjustment of closing pressure (35-60 bar) of the HJ SIP valve is done by an adjustable screw on top of the pressure plug. The adjustable screw is kept in place by a lock cover and a screw.

-

Drain pipe

The drain pipe (T) is for the leak oil internally in the HJ SIP valve and is connected to the return pipe where the oil will be recirculated into the system.

-

Pressure pipe

The Pressure Pipe (P), is the oil inlet side of the HJ SIP valve.

The pressurized oil is pumped from the lubricator.

A strainer is mounted in the inlet of the HJ SIP valve at delivery. This must be removed after 500 running hours.